Remote analysis using aerosol sample transport

A sample transportation and aerosol technology, applied in the preparation of test samples, chemical analysis by combustion, material analysis, etc., can solve problems such as spikes, unreliable analysis results, false positive signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

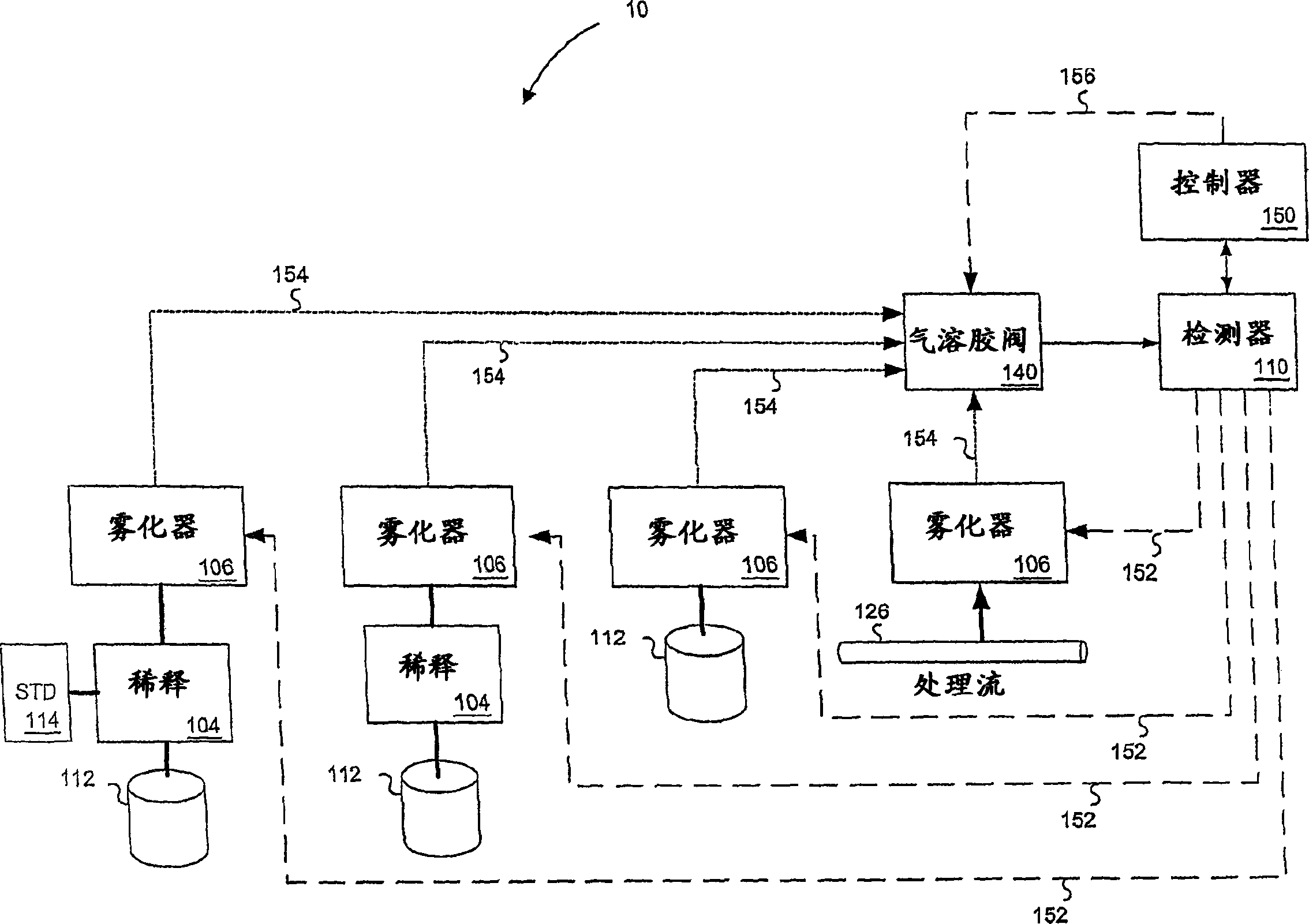

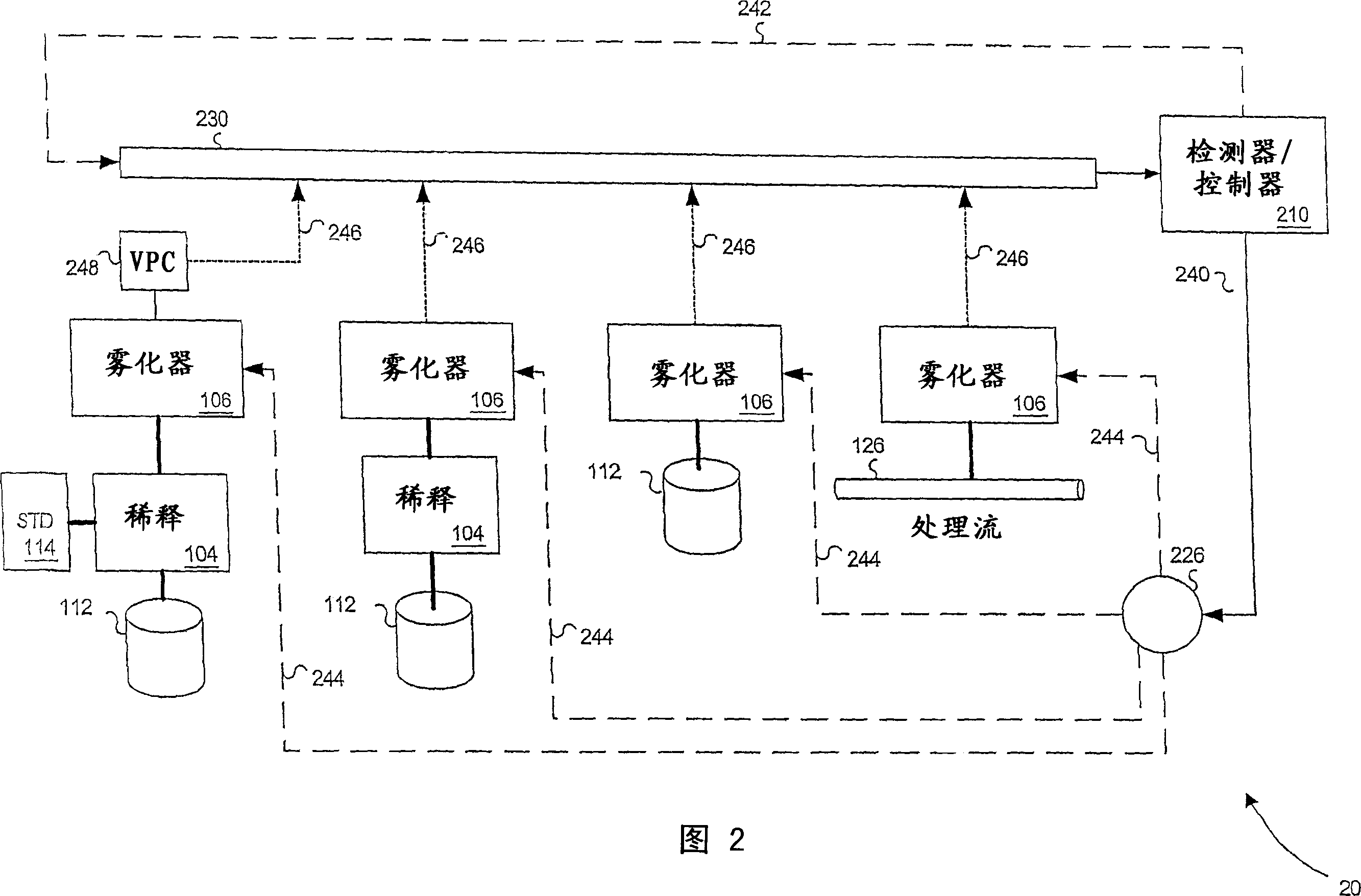

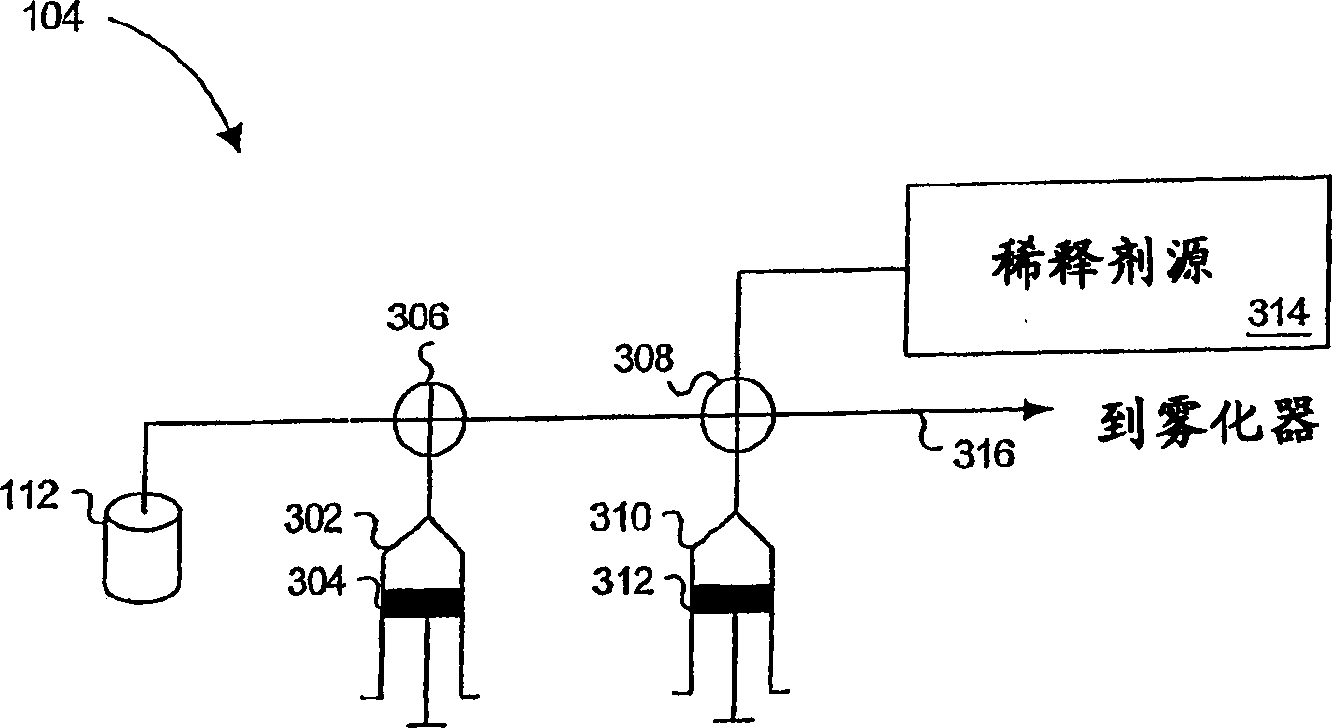

[0012] refer to figure 1 2, remote sampling systems 10 and 20 according to the present invention include the use of a remote nebulizer 106 to rapidly provide a sample in aerosol form to a central analyzer or detector 110, allowing the sample to be located at a considerable distance from the detector 110. distances, such as between different locations in a semiconductor manufacturing or petrochemical manufacturing enterprise.

[0013] An aerosol is a suspension of liquid droplets or solid particles in a gas. A wet aerosol is an aerosol comprising liquid droplets in the liquid phase. A dry aerosol is an aerosol in which there are substantially no suspended liquid droplets. Wet aerosols may also contain solid particles suspended in a dry gas. For example, a wet stream is a wet aerosol because it contains water droplets in liquid form. Dry aerosols can be produced by aerosolizing the sample at relatively low flow rates where the solvent exists essentially only in the gaseous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com