Side frame depression bar for liquid crystal display

A technology of liquid crystal display devices and beading, which is applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of insufficient holding force, the size of the visible area, the inability to play the role of fixing, and the small width of the frame, so as to save materials and save Full mold time, the effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The above and other purposes of the present invention will become more apparent through the following detailed description of preferred embodiments in conjunction with the accompanying drawings.

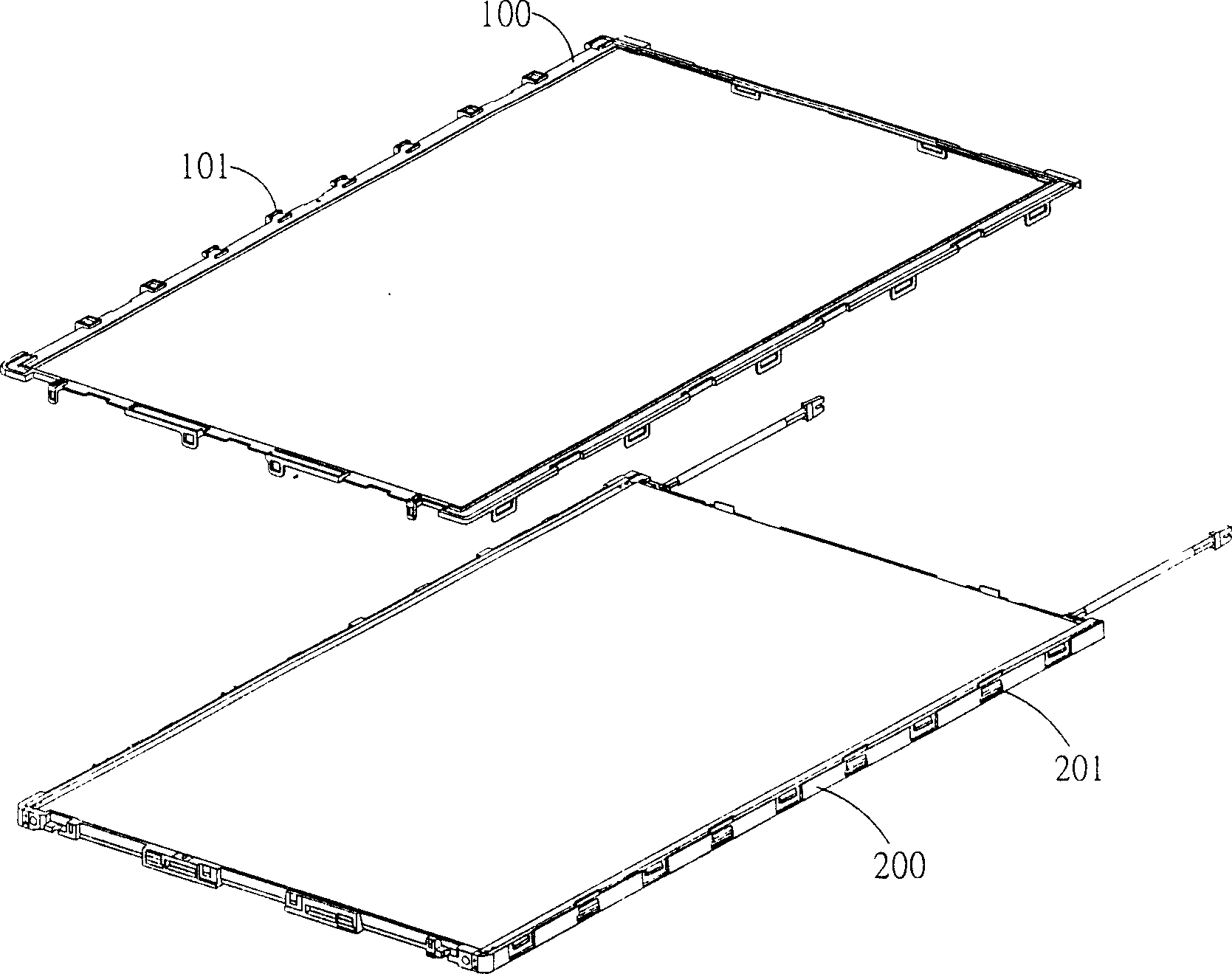

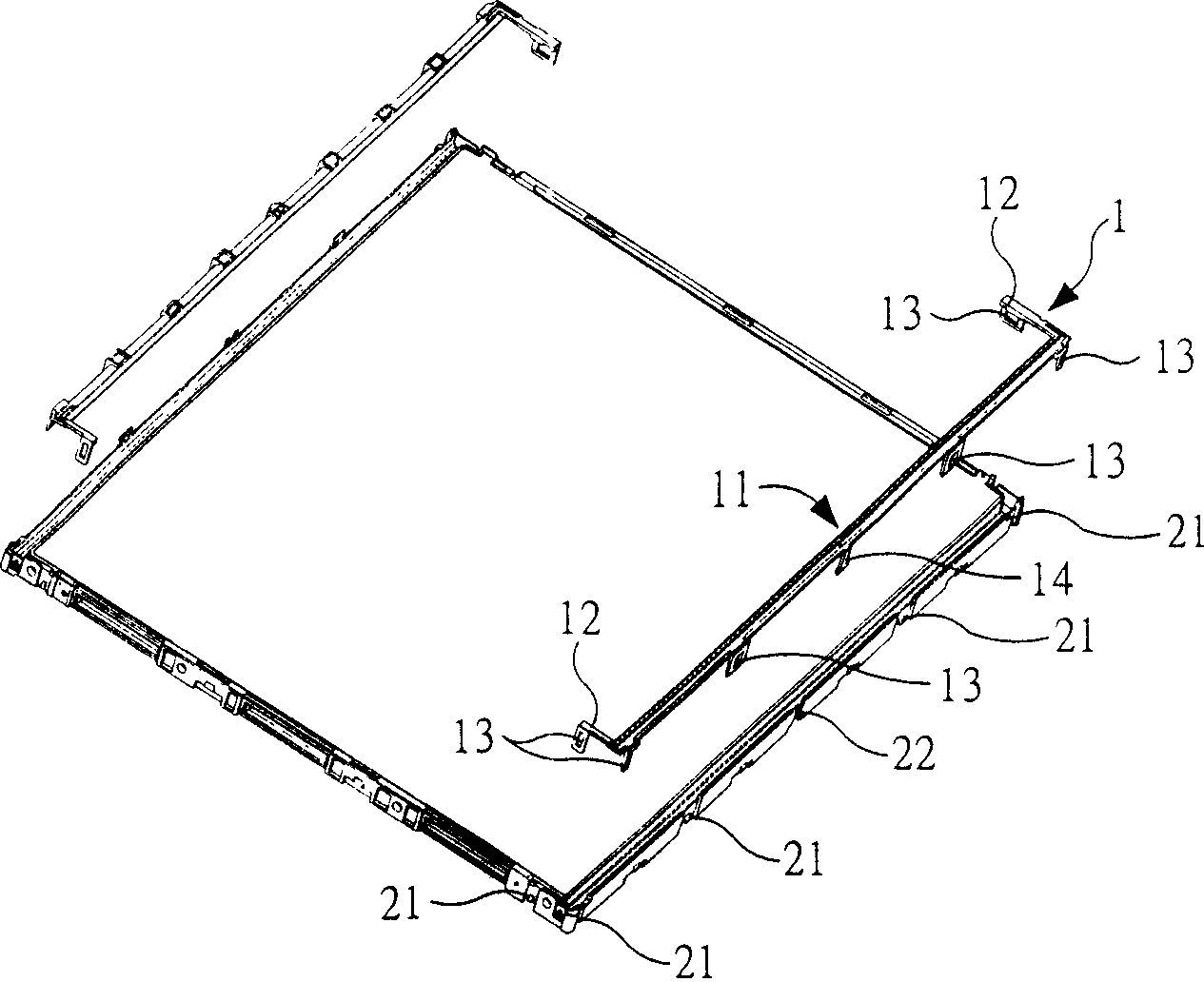

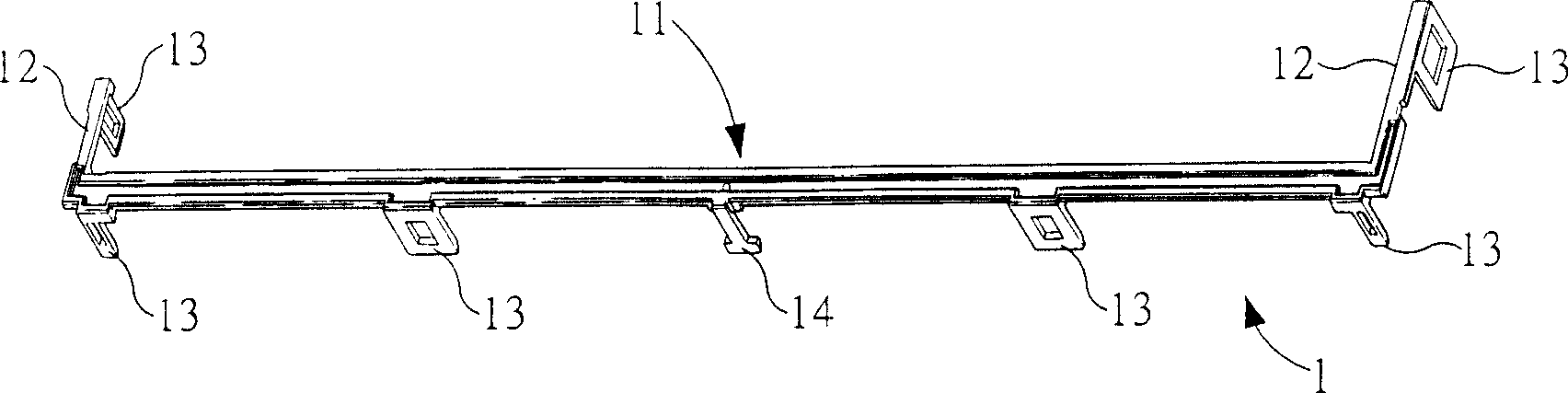

[0019] figure 2 It is a schematic diagram of the side frame bead 1 for the liquid crystal display device of the present invention and the supporting frame of the liquid crystal display device when they are not combined. image 3 The schematic view of the side frame bead 1 for liquid crystal display devices of this invention is shown. Depend on image 3 It can be seen that the side frame bead 1 for the liquid crystal display device of the present invention is mainly composed of a bead body 11 and a pair of extension parts 12 . The bead body 11 and the pair of extensions 12 form a "ㄇ" shape, and a plurality of fitting elements 13, 14 are provided on the bead body 11, and at the ends of the pair of extensions 12 are also provided with At least one fitting element 13 . The nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com