Waste heat utilizing loop-closing system of industrial furnace with producer gas as fuel

A technology for producing furnace gas and industrial furnaces and kilns, which is used in furnaces, waste heat treatment, furnace components, etc. to achieve high output, improve thermal efficiency of gasification, and improve thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

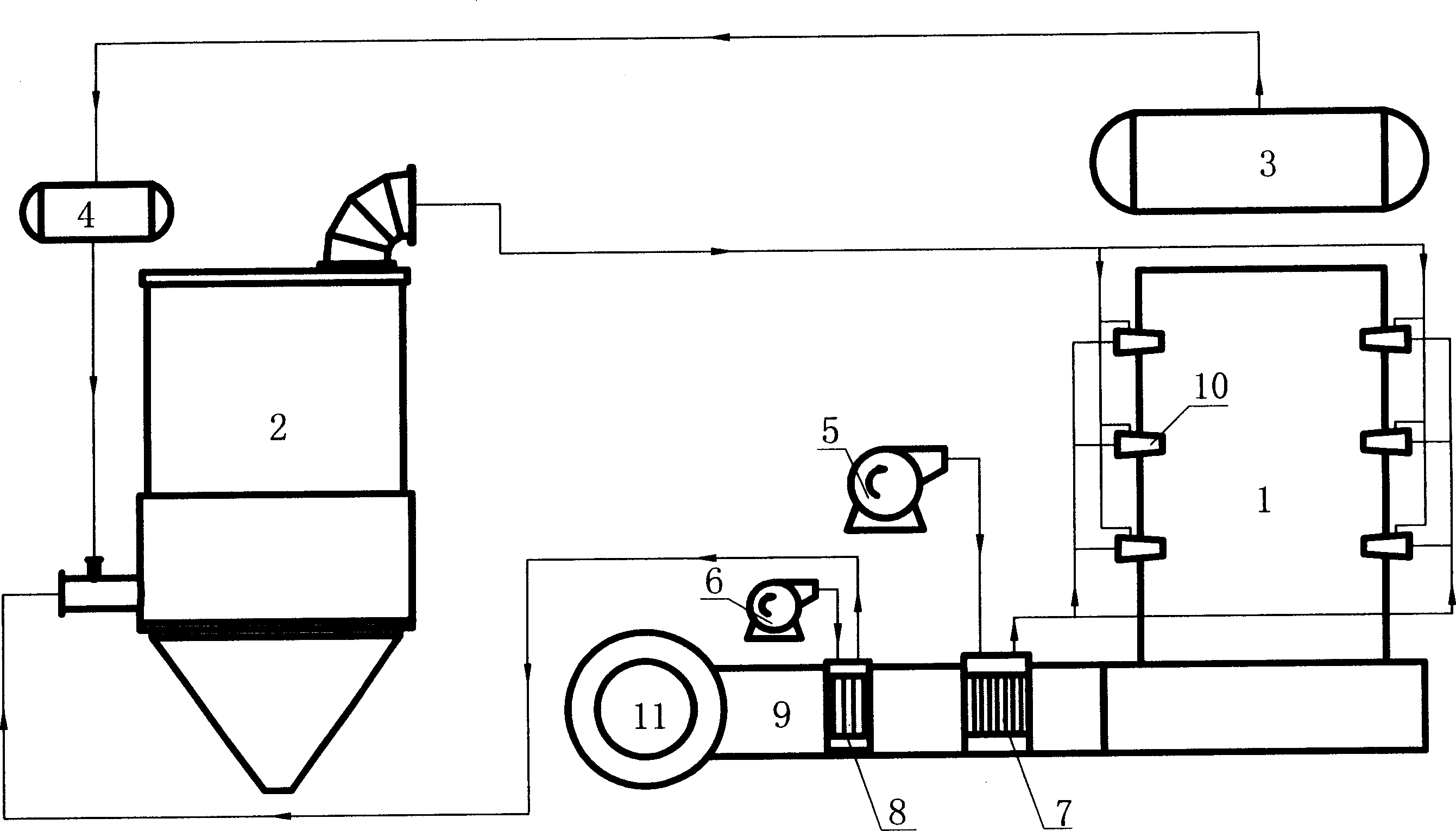

[0007] from figure 1 It can be seen that two heat exchangers are installed in series in the flue 9 outside the furnace 1 of the industrial furnace 1 burning hot dirty gas. The exchanger 8 exchanges heat. The hot air generated by the high-temperature heat exchanger 7 enters the industrial furnace for combustion, and the hot air generated by the low-temperature heat exchanger 8 enters the gasifier 2 as a gasification agent. The steam produced by the industrial furnace 1 adopts the vaporization cooling method to enter the sub-cylinder 4 from the steam drum 3; Saturated air enters the coal gasifier 2 as a gasifying agent, reacts with charcoal to generate hot dirty gas with high calorific value, and sends it to the hot dirty gas burner 10, and the industrial furnace uses a blower 5 to blow normal-temperature air into the high-temperature heat exchanger 7 , the preheated air enters the hot dirty gas burner 10 to support combustion, and the high-temperature flue gas produced enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com