Striped liquid personal cleansing compositions containing a cleansing phase and a separate benefit phase

A cleaning composition, striped technology, applied in the direction of detergent composition, surface active detergent composition, medical preparations containing active ingredients, etc., can solve the problem of incompatibility and uniform performance, high cost, cleaning phase Problems such as uneven distribution ratio of conditioning phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

[0174] The following examples described in Table 1 are non-limiting examples of cleansing phase and benefit phase compositions.

[0175] Table 1: Clean phase and benefit phase composition

[0176]

Example 1

Example 2

Example 3

ingredient

Weight percentage

(%)

Weight percentage

(%)

Weight percentage

(%)

I. Cleansing phase composition

Polyoxyethylene laureth-3 ammonium sulfate

3.0

3.0

3.0

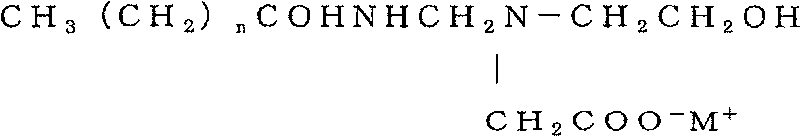

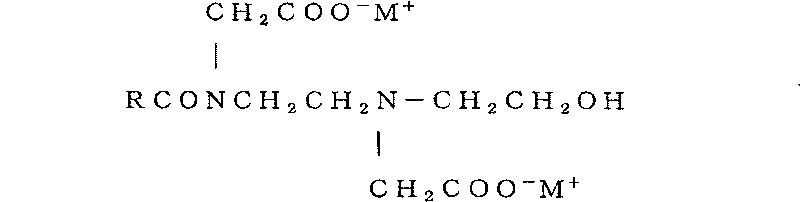

N-Lauroamido ethyl-N-hydroxyethyl sodium acetate

(Miranol L-32Ultra, available from Rhodia)

16.7

16.7

16.7

1.0

1.0

1.0

0.9

0.9

0.9

Tris(hydroxystearic acid) glyceride (Thixcin R)

2.0

2.0

2.0

Guar Hydroxypropyl Trimethyl Ammonium Chloride

(N-Hance 3196, available from Aqualon)

0.17

0.75

0.75

[0177]

Example 1

Example 2

Example 3

Guar Hydroxypropyl Trimethyl Ammonium Chloride (Jaguar

C-17, available from Rhodia)

0.58

-

-

(UCARE polymer JR-30M, available from Amerchol)

...

Embodiment 4 to 6

[0185] The following examples described in Table 2 are non-limiting examples of the cleansing phase and benefit phase compositions of the present invention.

[0186] Table 2: Cleansing phase and benefit phase composition

[0187]

[0188] The above composition is prepared by conventional formulation and mixing techniques. The cleansing phase composition was prepared by first adding citric acid to water in a ratio of 1:3 to form a citric acid premix. Then, in the following order, add the following ingredients to the main mixing vessel: water, Miracare SLB-354, sodium chloride, sodium benzoate, disodium edetate, 1,3-dimethylol-5,5 -Dimethylhydantoin. Start the mixing of the main mixing vessel. In another mixing vessel, the dispersing polymer (polyquaternary amine 10, Jaguar C-17 or N-Hance 3196) was added to the water at a ratio of 1:10 and formed a polymer premix. Under continuous stirring, add the fully dispersed polymer premix to the main mixing vessel. Disperse Polyox WSR 3...

Embodiment 7 to 9

[0192] The following examples described in Table 3 are non-limiting examples of the cleansing phase and benefit phase compositions of the present invention.

[0193] Table 3: Clean phase and benefit phase composition

[0194]

[0195] The above composition is prepared by conventional formulation and mixing techniques. The cleansing phase composition was prepared by first adding citric acid to water in a ratio of 1:3 to form a citric acid premix. Then, in the following order, add the following ingredients to the main mixing vessel: water, Miracare SLB-354, sodium chloride, sodium benzoate, disodium edetate, 1,3-dimethylol-5,5- Dimethylhydantoin. Start the mixing of the main mixing vessel. Then, the fragrance is added to the batch. Continue stirring until a homogeneous solution is formed.

[0196] Prepare the benefit phase by adding Versagel to the mixing vessel. Heat the container to 190°F. Then, add cosmetic pigments while stirring. Allow the container to cool under slow st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com