Diwu saponin W3 standard product extracted from Linyin anemone and preparing process

A kind of technology of kinarin and diwu, applied in the field of diwusaponin W3 standard product and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

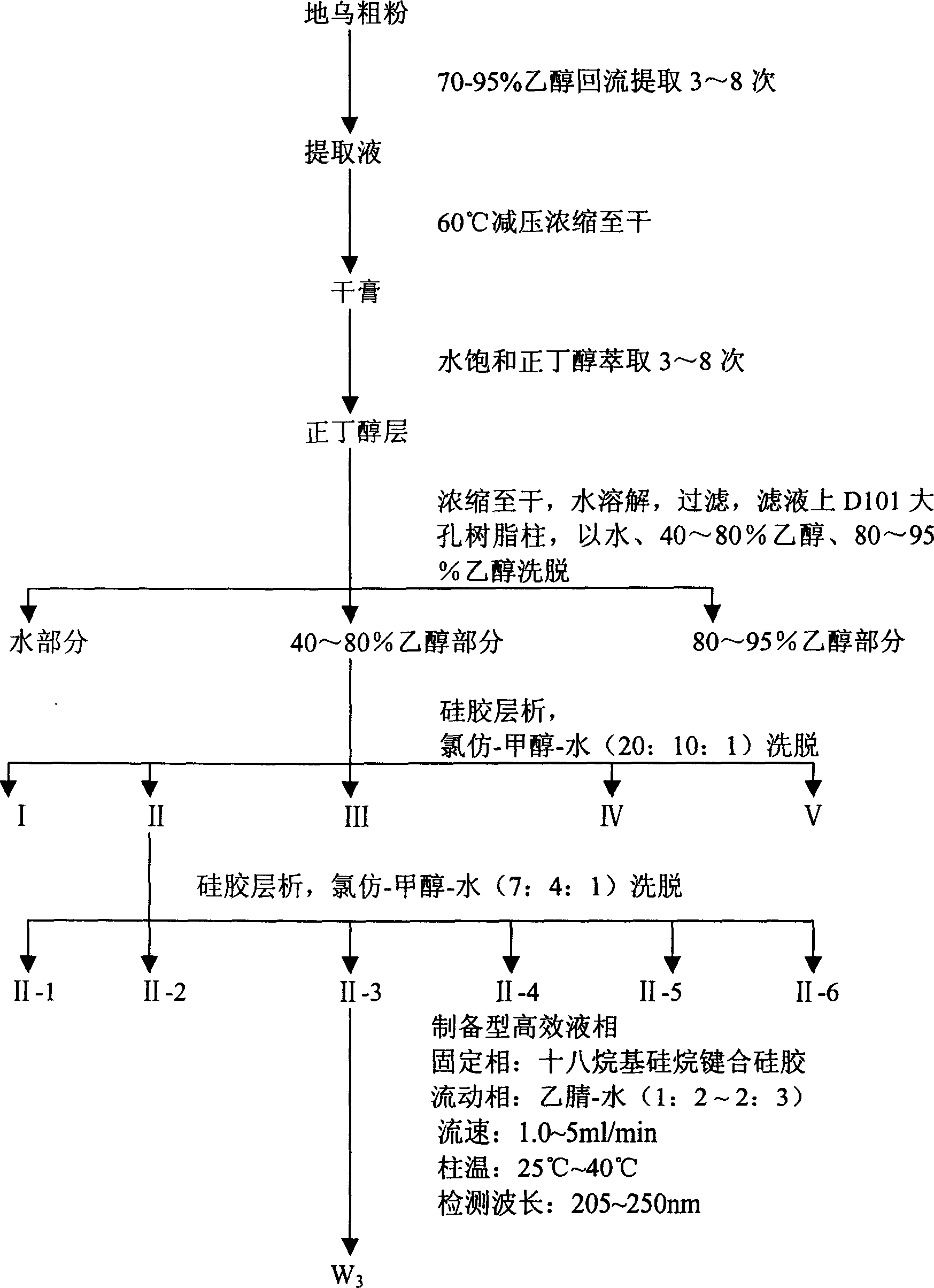

[0017] Extract and isolate diguanin W from Diwu 3 process such as figure 1 As shown, take Diwu coarse powder, heat and reflux extraction with 70-95% ethanol for 3 times, each time for 3 hours, combine the extracts, concentrate to dryness under reduced pressure at 60°C, and obtain dry extract; suspend the dry extract in water , extracted 3 times with water-saturated n-butanol, and the n-butanol layer was concentrated to dryness under reduced pressure to obtain n-butanol dry extract; , 40-80% ethanol, 80-95% ethanol elution; collect 40-80% ethanol eluate, reclaim ethanol and evaporate to dryness in a water bath to obtain diglucoside; carry out silica gel chromatography with chloroform:methanol : Water was eluted with a mixture of 20:10:1 volume ratio, roughly divided into 5 sections, detected by TLC, and collected rich in diguanin W 3 Part of the second paragraph, then silica gel chromatography, eluted with a mixture of chloroform:methanol:water at a volume ratio of 7:4:1, TLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com