Light emitting device and fabrication method thereof and light emitting system using the same

A technology for light-emitting devices and light-emitting elements, applied in the field of light-emitting systems, can solve problems such as difficulty in production, increased cost, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] The light-emitting device according to the present invention can be implemented in various ways, and its preferred

[0032] Example.

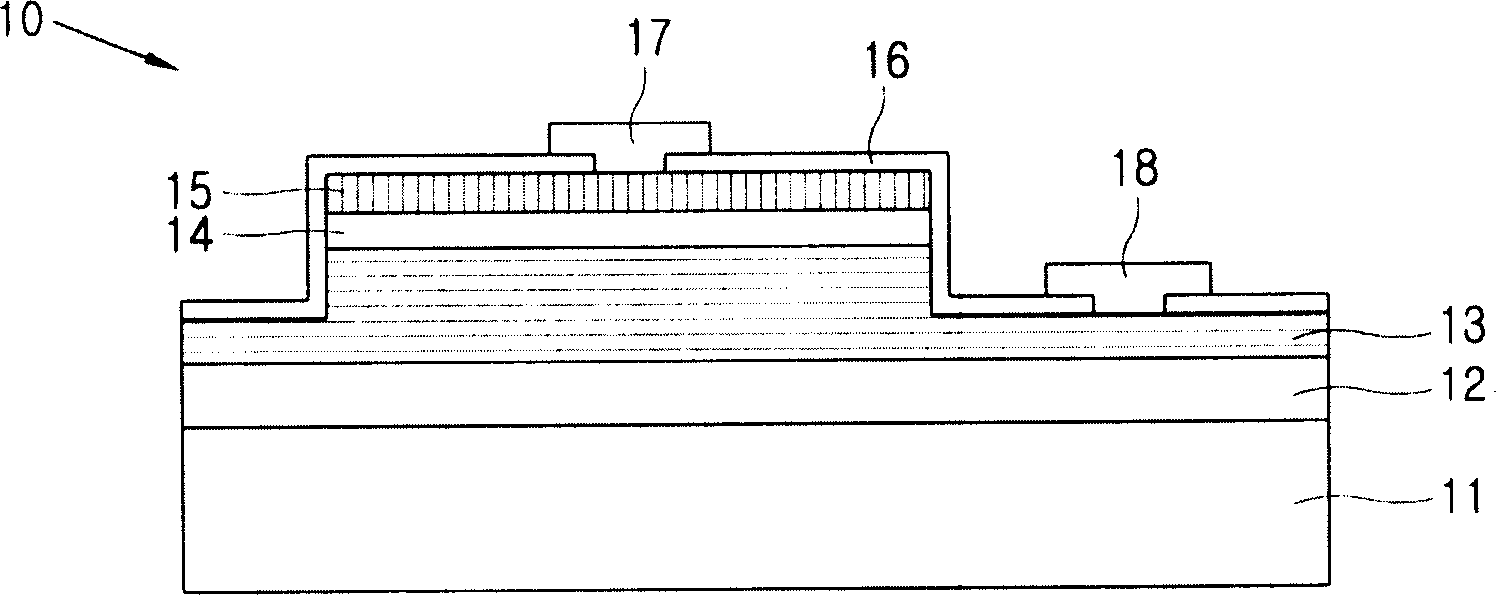

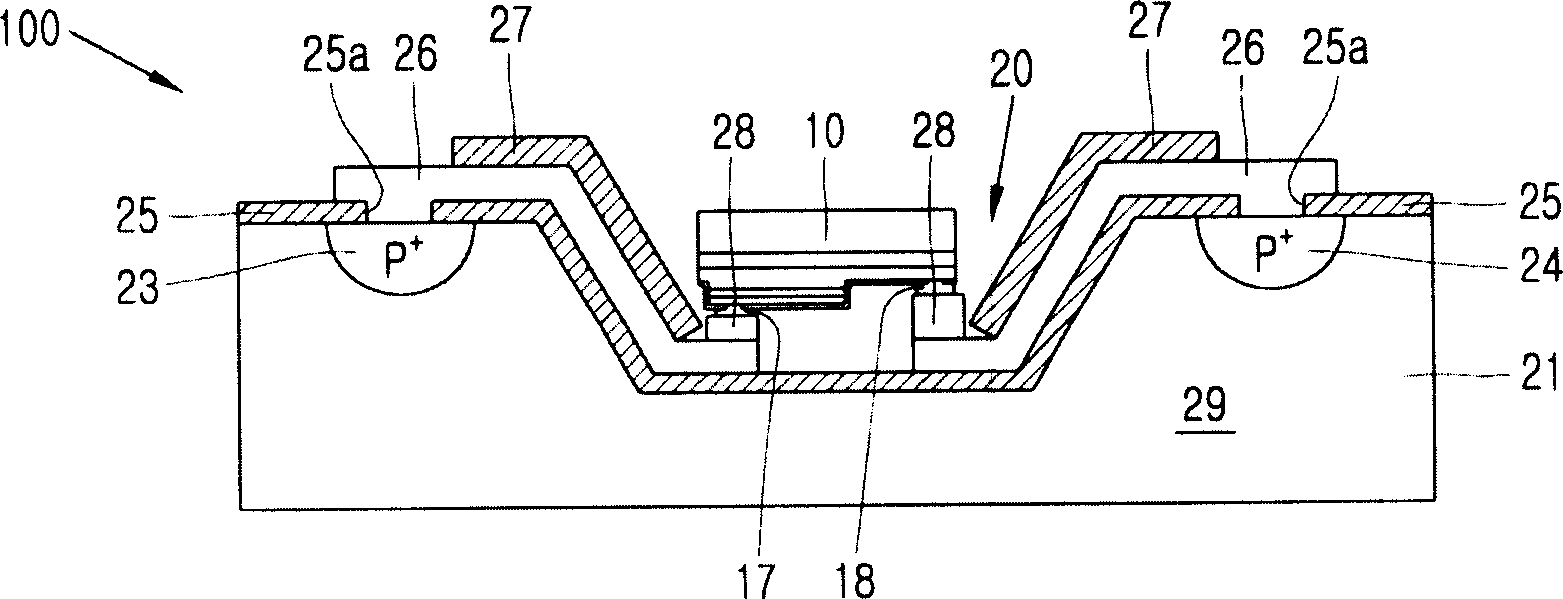

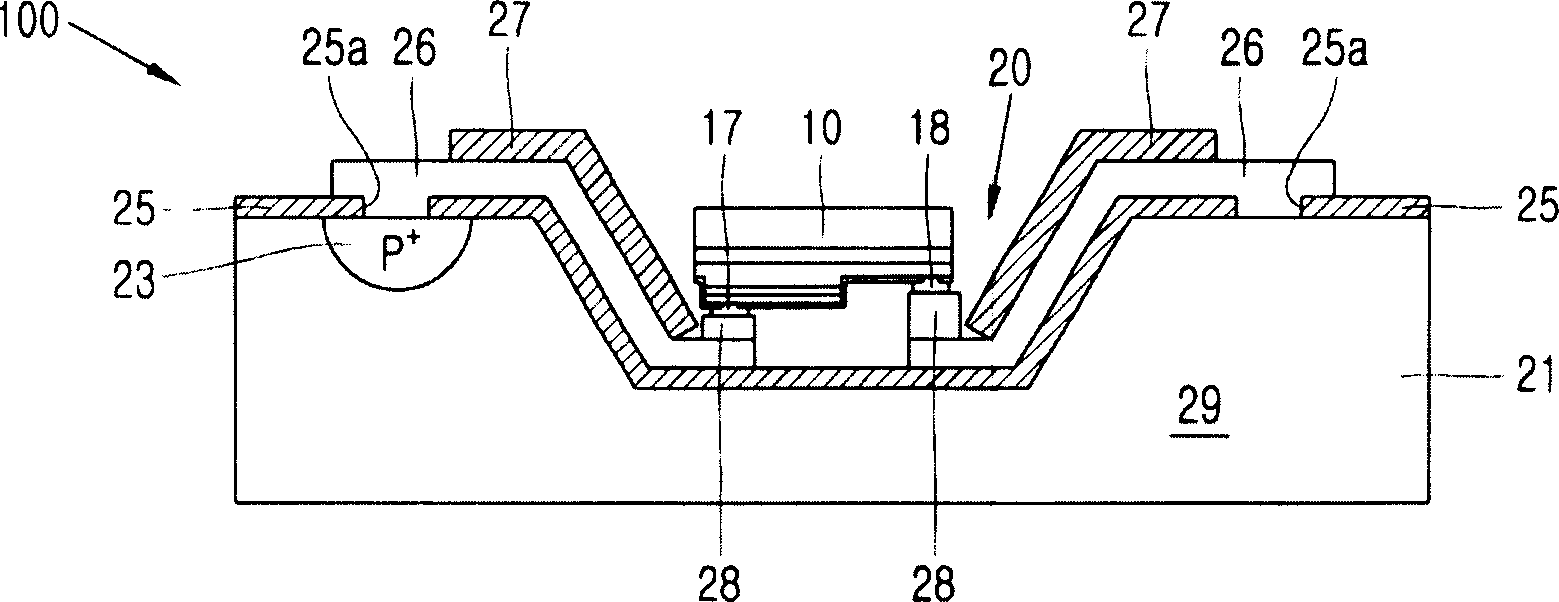

[0033] figure 2 is a cross-sectional view of the light emitting device according to the first embodiment of the present invention.

[0034] As shown in the figure, a light emitting device 100 according to a first embodiment of the present invention includes a light emitting element 10 having a first electrode 17 and a second electrode 18, and a cavity 20 having a light emitting element 10 mounted therein on its main surface and The semiconductor component 21 is electrically connected to the light emitting element 10 .

[0035] The depth of the hole 20 is preferably greater than the height of the light emitting device 10 so that the light emitted by the light emitting element 10 will not affect other elements and the overall size of the light emitting device 100 can be minimized.

[0036] The semiconductor member 21 is made of a silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com