Method for preparing MCM-22, molecular sieve

A technology of MCM-22 and synthesis method, which is applied in the field of synthesis of MCM-22 molecular sieves, can solve problems that have not been reported, and achieve the effect that the method is simple and beneficial to industrial production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of the first step reaction mixture

[0026] Molar ratio of Al in aluminum source 2 o 3 : SiO in silicon source 2 : Na in alkali source 2 O: organic templating agent: H 2 O is 0.033: 1: 0.045: 0.35: 15 to prepare the reaction mixture, then add the MCM-22 molecular sieve crystal seed crystal of 5% of the dry basis weight of the mixture to the reaction mixture, the aluminum source is sodium metaaluminate, and the silicon source is silica sol, The alkali source is sodium hydroxide, and the content of HMI in the organic template is 100%;

[0027] The second step of hydrothermal crystallization

[0028] The reaction mixture obtained in the first step was hydrothermally crystallized at 140° C. for 5 days, filtered, washed, dried, and calcined to obtain the product MCM-22 molecular sieve.

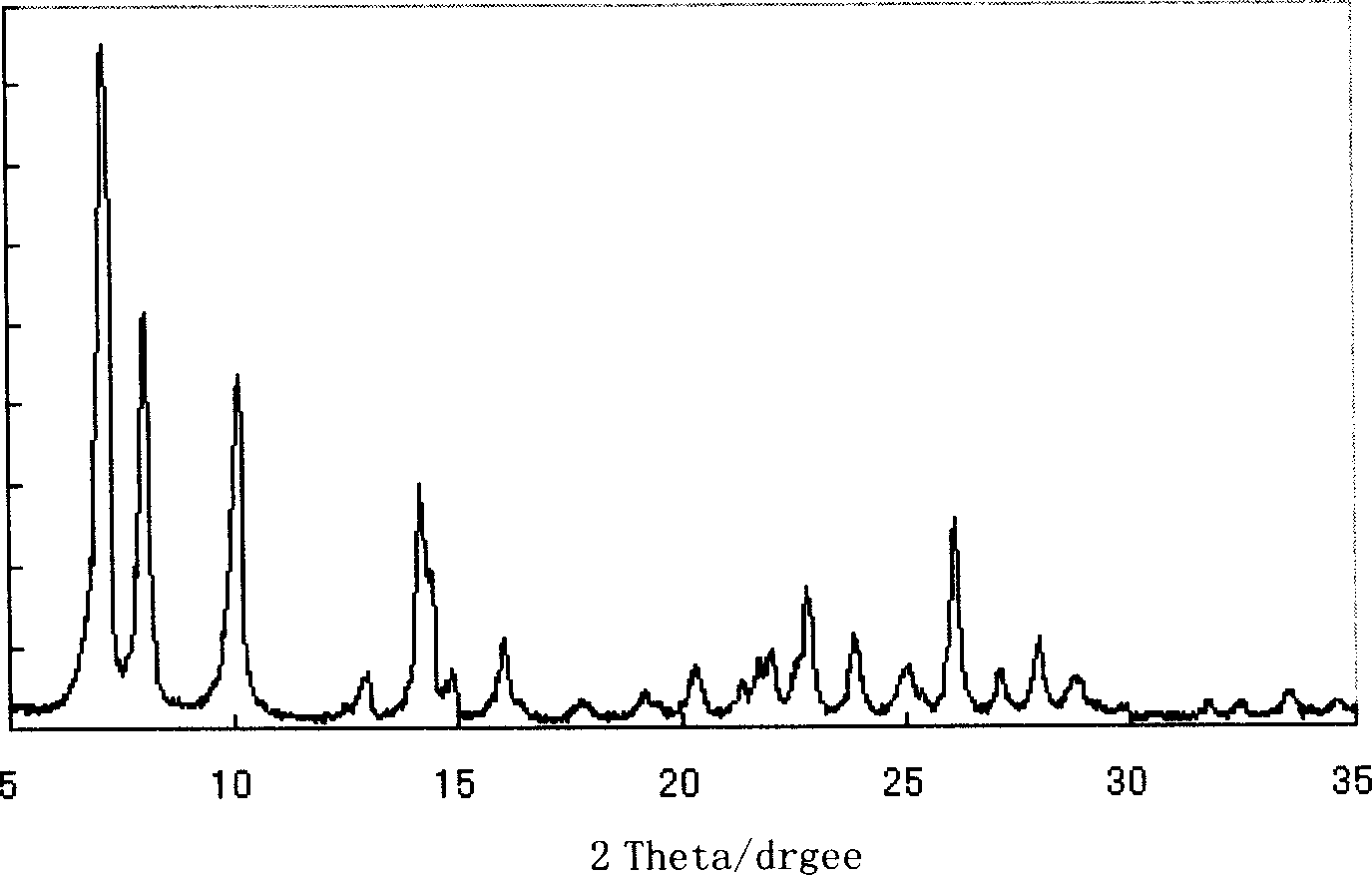

[0029] The product that obtains, MCM-22 molecular sieve, its XRD spectrogram is as figure 1 shown. The grain size of the molecular sieve was tested by a scanning electron...

Embodiment 2~5

[0031] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0032] Preparation of the first step reaction mixture

Embodiment 2

[0033] Example 2 The content of HMI in the organic template is 70%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com