Developing method and developing device using the same

一种显影方法、显影装置的技术,应用在显影剂、应用电荷图形的电记录工艺、应用电荷图形的电记录工艺等方向,能够解决图像浓度变化和摩擦变化少等问题,达到良好画质、全面均匀性高、防止调色剂残余的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

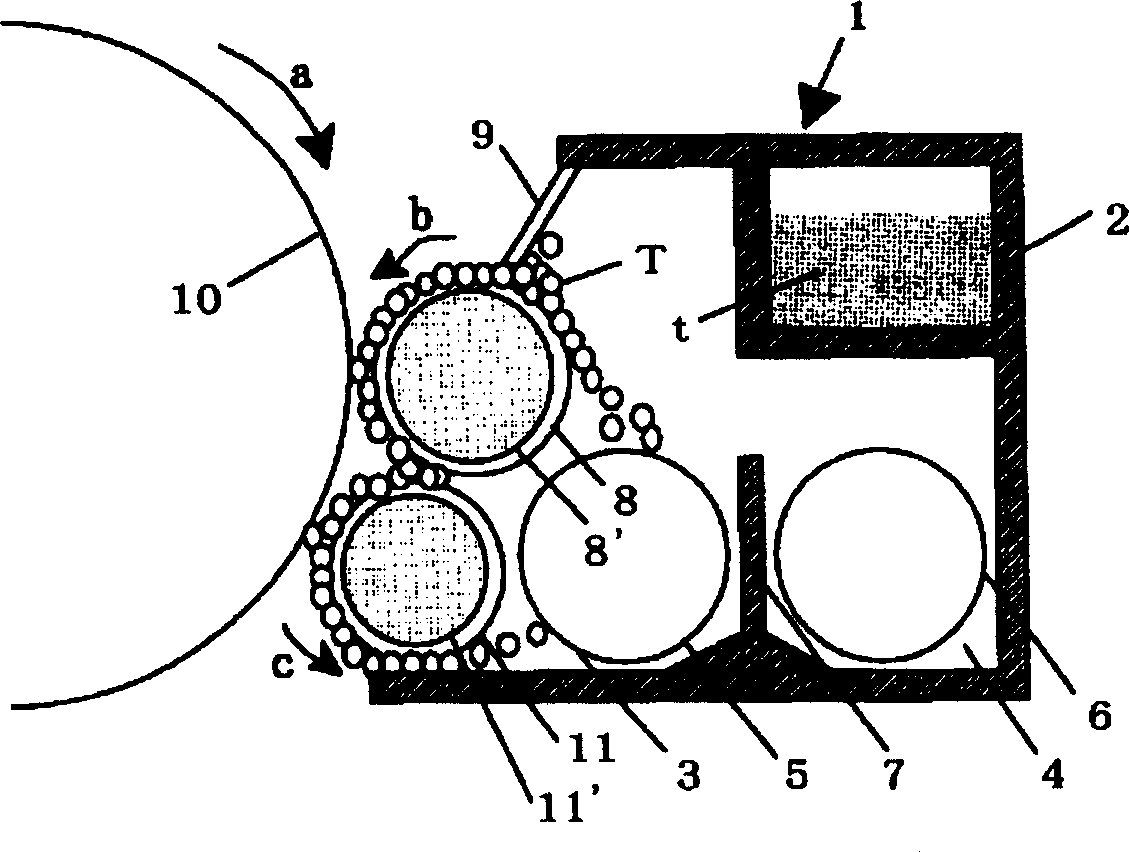

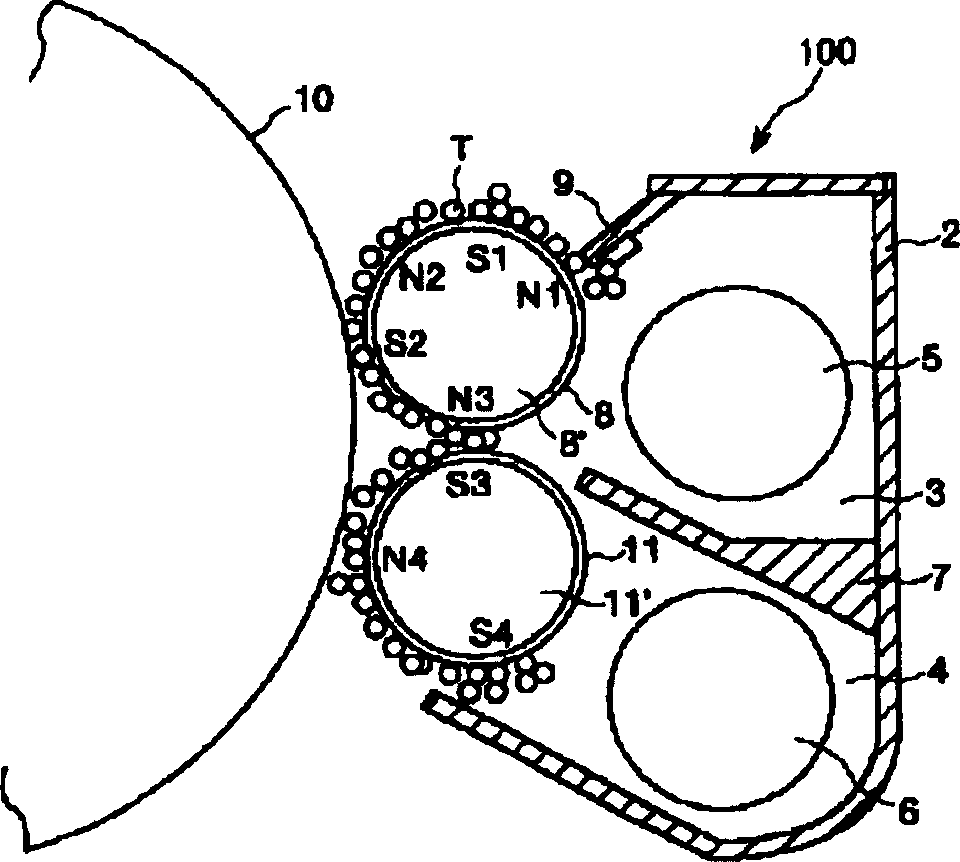

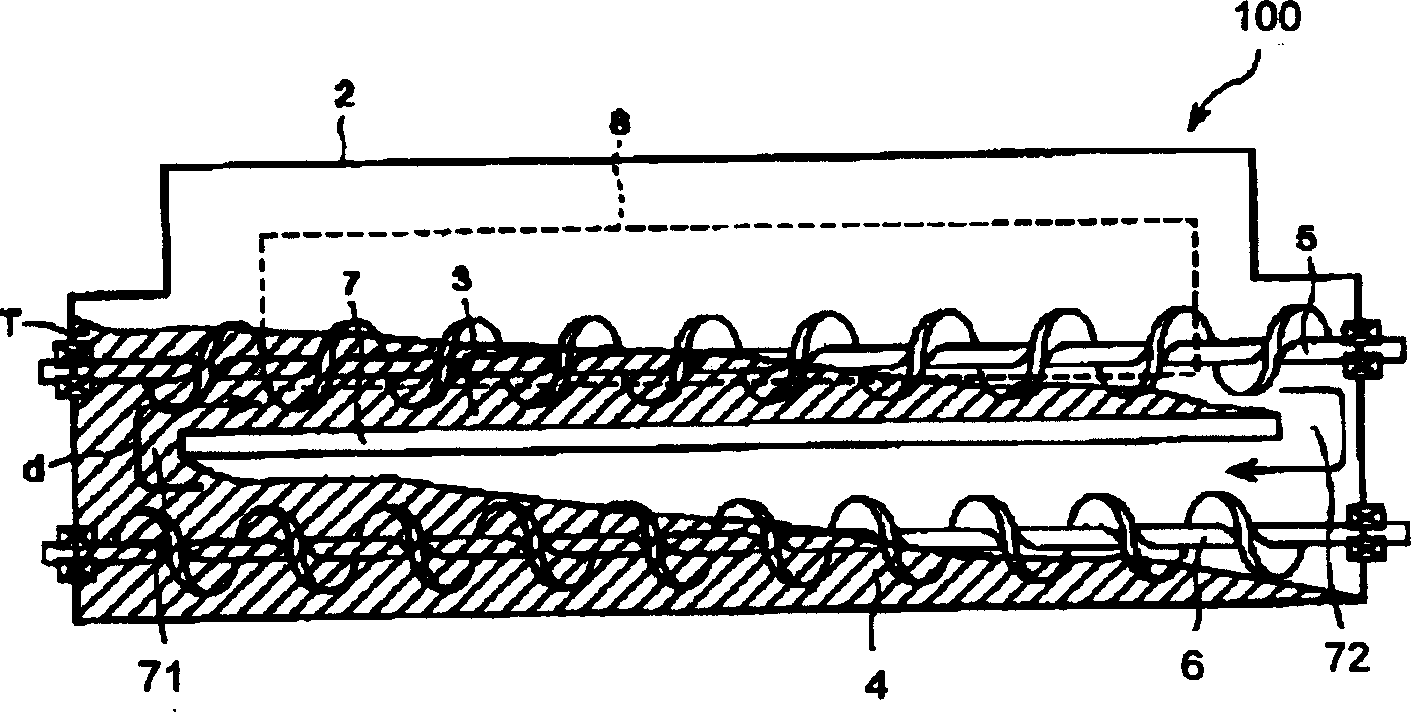

Method used

Image

Examples

preparation example Construction

[0253] Preparation of toner dispersion

[0254] First, an aqueous solution having a volume mixing ratio of methanol:water of 45:55 was prepared. 10 ml of this aqueous solution was put into a 30 ml sample container (Nichiden Rika Glass: SV-30), 20 mg of toner was added to the liquid surface, and the container was capped. After that, use a Yayoi vibrator (style: YS-LD) at 2.5S -1 Vibrate for 10 seconds. At this time, the angle of vibration is such that if the directly above (vertical) of the vibrator is regarded as 0 degrees, the vibrating pillar is moved 15 degrees in front and 20 degrees in the rear. The sample container is fixed on a fixing bracket (fixing the cover of the sample container on the extension line of the post) installed in front of the post. After taking out the sample container, the dispersion liquid after 30 seconds was used as the dispersion liquid for measurement.

[0255] Determination of transmittance

[0256] The above-mentioned dispersion liquid was...

Embodiment

[0290] Hereinafter, the present invention will be described in more detail based on specific production examples and examples, but the present invention is not limited thereto.

manufacture example

[0292] As the material of the ethylene copolymer unit, 10 parts by weight of styrene, 5 parts by weight of 2-ethylhexyl acrylate, 2 parts by weight of fumaric acid, and 5 parts by weight of α-methylstyrene dimer are added with diperoxide Cumyl was added to the dropping funnel. In addition, as a material for the polyester unit, 25 parts by weight of polyoxypropylene (2.2)-2,2-bis(4-hydroxyphenyl)propane, 15 parts by weight of polyoxyethylene (2.2)-2,2-bis(4 -Hydroxyphenyl) propane, 9 parts by weight of terephthalic acid, 5 parts by weight of trimellitic anhydride, 24 parts by weight of fumaric acid and dibutyltin oxide add in the four-necked flask made of glass of 4L, install on the four-necked flask A thermometer, a stirring rod, a condenser, and a nitrogen inlet tube were used to set the four-neck flask in a mantle-type resistance heater. Next, after replacing the inside of the four-necked flask with nitrogen, the temperature was slowly raised while stirring, and at a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com