Multiple choke coil and electronic equipment using the same

A technology of choke coils and coils, applied in circuits, inductors, electrical components, etc., can solve problems such as uneven inductance values, small DC resistance values, and increased heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

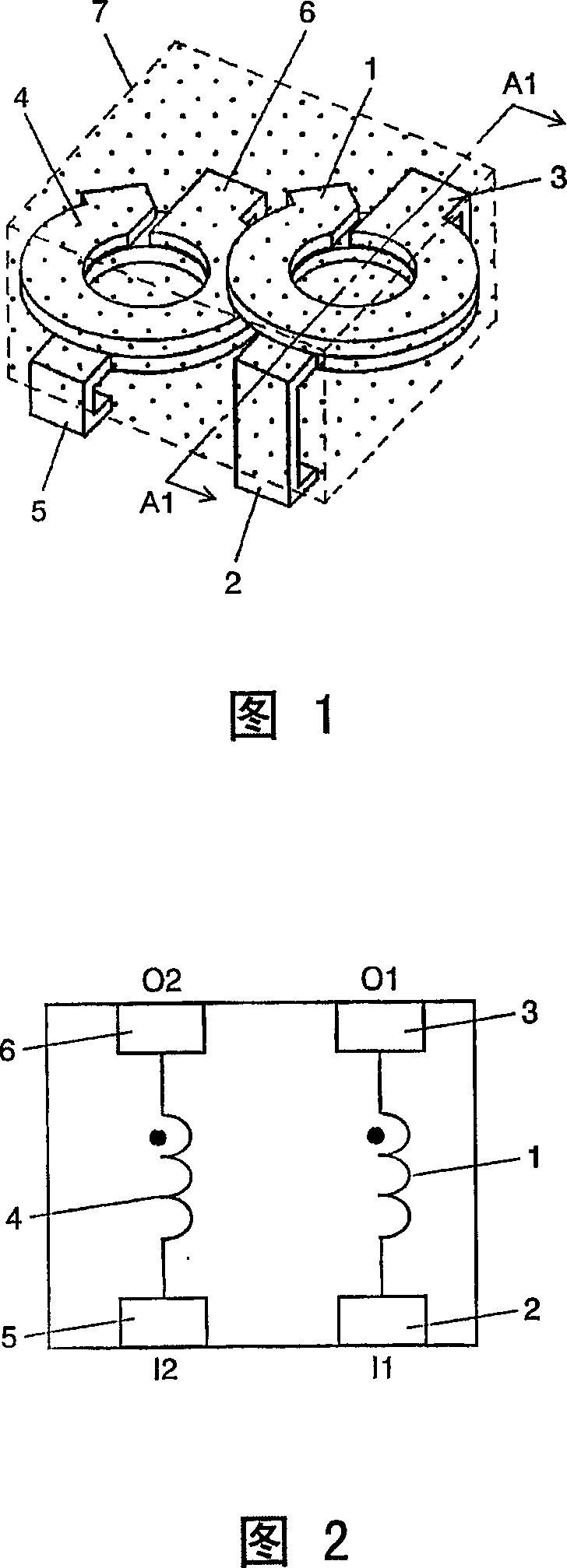

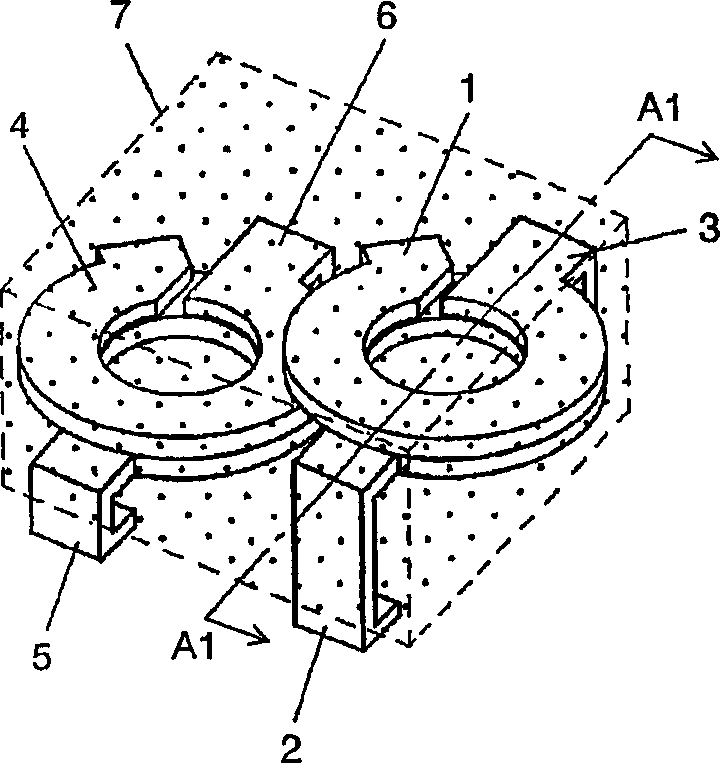

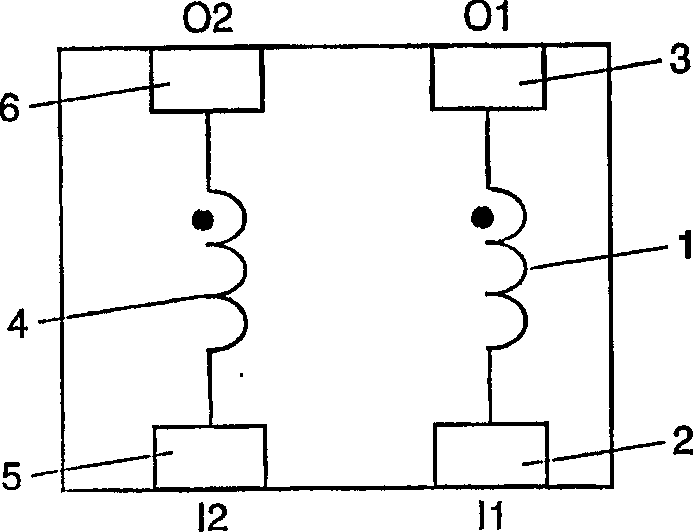

[0146] Fig. 1 is a perspective perspective view of a multiple choke coil according to Embodiment 1 of the present invention. And Figure 2 is the wiring diagram of the multiple choke coil. The first coil 1 is composed of a first input terminal 2 and a first output terminal 3 which are integrally formed. The second coil 4 is likewise composed of a second input terminal 5 and a second output terminal 6 formed integrally. The first coil 1 and the second coil 4 are wound in the same direction, and their number of turns is 1.5 turns. In this way, when current flows from the first input terminal 2 of the first coil 1 and the second input terminal 5 of the second coil 4, the directions of the magnetic fluxes in the coils of the first coil 1 and the second coil 4 are the same. direction.

[0147] In addition, the central axis of the first coil 1 and the central axis of the second coil 4 are parallel, and they are arranged such that the first coil 1 is located in the upper layer and ...

Embodiment 2

[0176] Next, a multiple choke coil according to Embodiment 2 of the present invention will be described with reference to FIGS. 7 to 10 . Although the basic structure of the multiple choke coil of this embodiment is the same as the multiple choke coil of Embodiment 1 of the present invention, the feature of this embodiment is that a terminal-integrated coil is added and arranged in a V shape. .

[0177] Fig. 7 is a perspective perspective view of the multiple choke coil of this embodiment. And Fig. 8 is the wiring diagram of this multiple choke coil. The first coil 71 integrates the first input terminal 72 and the first output terminal 73 . In the second coil 74, the second input terminal 75 and the second output terminal 76 are similarly integrated. In addition, the third coil 77 also integrates the third input terminal 78 and the third output terminal 79 . The winding direction of each coil is the same, and the number of turns is 1.5 turns. In this way, when a current f...

Embodiment 3

[0204] Next, a multiple choke coil according to Embodiment 3 of the present invention will be described with reference to FIGS. 15 and 16 . The basic structure of the multiple choke coil of this embodiment is the same as that of the multiple choke coil of the first embodiment.

[0205] Fig. 15 is a perspective perspective view of the multiple choke coil of this embodiment. The first coil 131 , the second coil 132 and the third coil 133 are the same as the coils used in the multiple choke coil of the first embodiment, and are composed of terminal-integrated coils formed by stamping and folding a metal plate. The number of turns of each coil is 2.5 turns.

[0206] Fig. 16 is a sectional view along line B2-B2 of the multiple choke coil shown in Fig. 15 . The central axis of the first coil 131, the central axis of the second coil 132 and the central axis of the third coil 133 are parallel to each other, and are arranged such that the first coil 131 and the third coil 133 are loc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com