Instant jellyfish food product, and its product, method

A production method and jellyfish technology are applied in the field of ready-to-eat jellyfish products and production, which can solve the problems of difficulty in guaranteeing the quality of rough processed pickled jellyfish, large loss of nutrients, long production cycle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

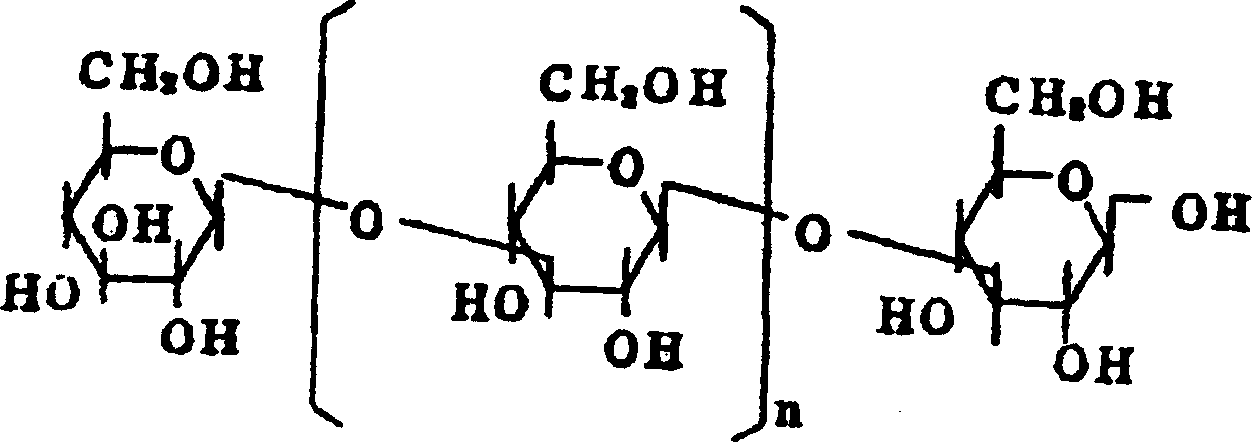

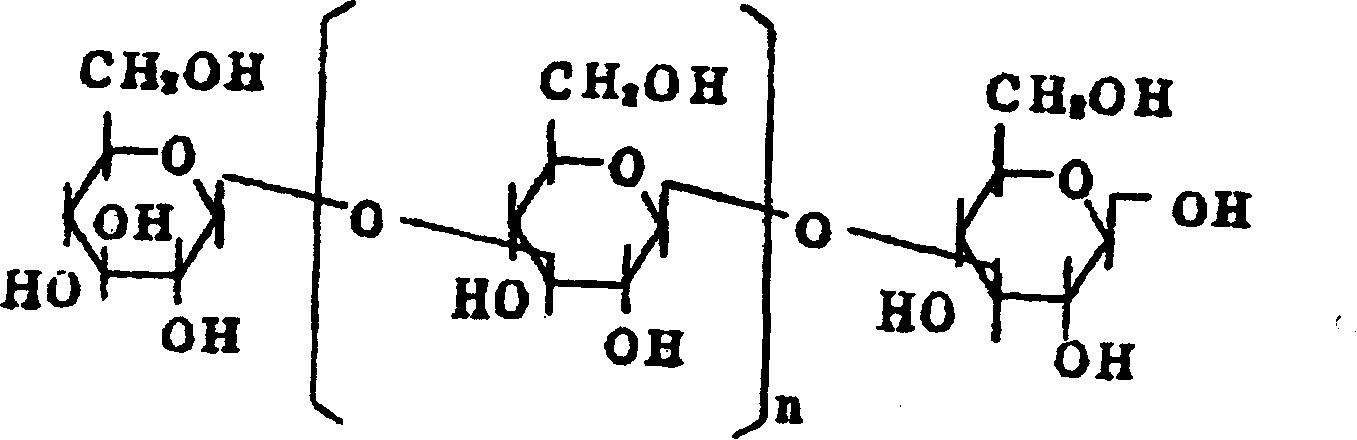

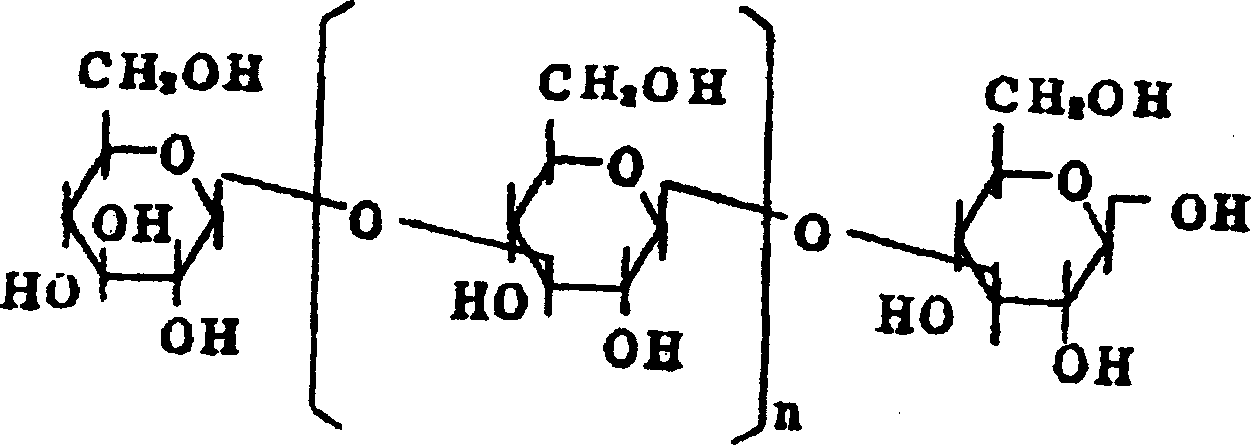

[0028] Take the freshly caught jellyfish (fresh jellyfish), cut it into strips and remove impurities, wash with water, and put the jellyfish strips in hot water to remove salt as needed, repeat the desalination process again after cooling, and let it stand for 2 ~ 3 days to remove fishy smell. The jellyfish strips are pulverized by a high-speed rotary grinder to make jellyfish paste. While crushing, you can add thermal gelling polysaccharide named CRADRUN produced by Takeda Kirin Co., Ltd. in Japan. The amount added is 0.5-5.0% of the jellyfish jelly. If the jellyfish jelly is 20 kg, you can add 0.1 kg or 1 kg of CRADRUN. . Put the mixture of jellyfish paste and CRADRUN into a mold and heat it to 80-120°C with hot water, steam or direct fire until the mixture is gelled. Usually, the heating time is 20-120 minutes. The heating temperature and time are related to the amount of CRADRUN added. The more CRADRUN is added, the lower the heating temperature and the heating time. Th...

Embodiment 2

[0030] Take 12 kg of pickled jellyfish sold in the market, cut it into short strips with a width of 5-10mm and remove impurities, put it in a washing machine for cleaning, and put the jellyfish strips in hot water to remove salt as needed , After cooling, repeat the desalination process again, and let it stand for 2 to 3 days to remove the fishy smell. Move the cleaned jellyfish strips to a water tank, add water containing 1% bleach and stir repeatedly, wait until the color of the pickled jellyfish turns yellowish white, let it stand, and then wash repeatedly until there is no bleach smell, and then dehydrate. Get 1 kilogram of processed pickled jellyfish strips, add 0.5 kilograms of concentration and add 0.5 kilograms of thermal gelation polysaccharide solution named CRADRUN produced by Japan Takeda Kirin Co., Ltd., put it into a high-speed rotary grinder and pulverize the jellyfish strips, into jellyfish paste. Put the mixture of jellyfish paste and CRADRUN into roll-shaped...

Embodiment 3

[0033] Take pickled jellyfish sold in the market, cut it into short strips with a width of 5-10mm and remove impurities, put it in a washing machine for cleaning, and put the jellyfish strips in hot water to remove salt, cool Then repeat the desalination process again, and let it stand for 2 to 3 days to remove the fishy smell. Get 1 kilogram of processed pickled jellyfish strips, adding 0.1 kilogram of concentration is the thermogelling polysaccharide dissolving solution and 0.0005~0.025 kilogram of thermocoagulant ( Bone collagen, carrageenan, cold weather, etc.), put it into a high-speed rotary grinder to crush the jellyfish strips to make jellyfish pulp. Put the mixture of jellyfish paste and CRAD-RUN into roll-shaped, plate-shaped, rod-shaped molds, etc., heat the mold with hot water, steam or direct fire, and heat at 90°C for 60-120 minutes. Afterwards, the gelled jellyfish is cooled immediately, which can be carried out in a water tank or a refrigerator, or directly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com