Sputtering target and sputtering method using the target

A sputtering and sputtering device technology, applied to the sputtering target and the sputtering field using the target, can solve the problems of reproducibility of film formation, abnormal discharge, particle generation, etc., to prevent abnormal discharge and particles production, high target service efficiency, and high film formation reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

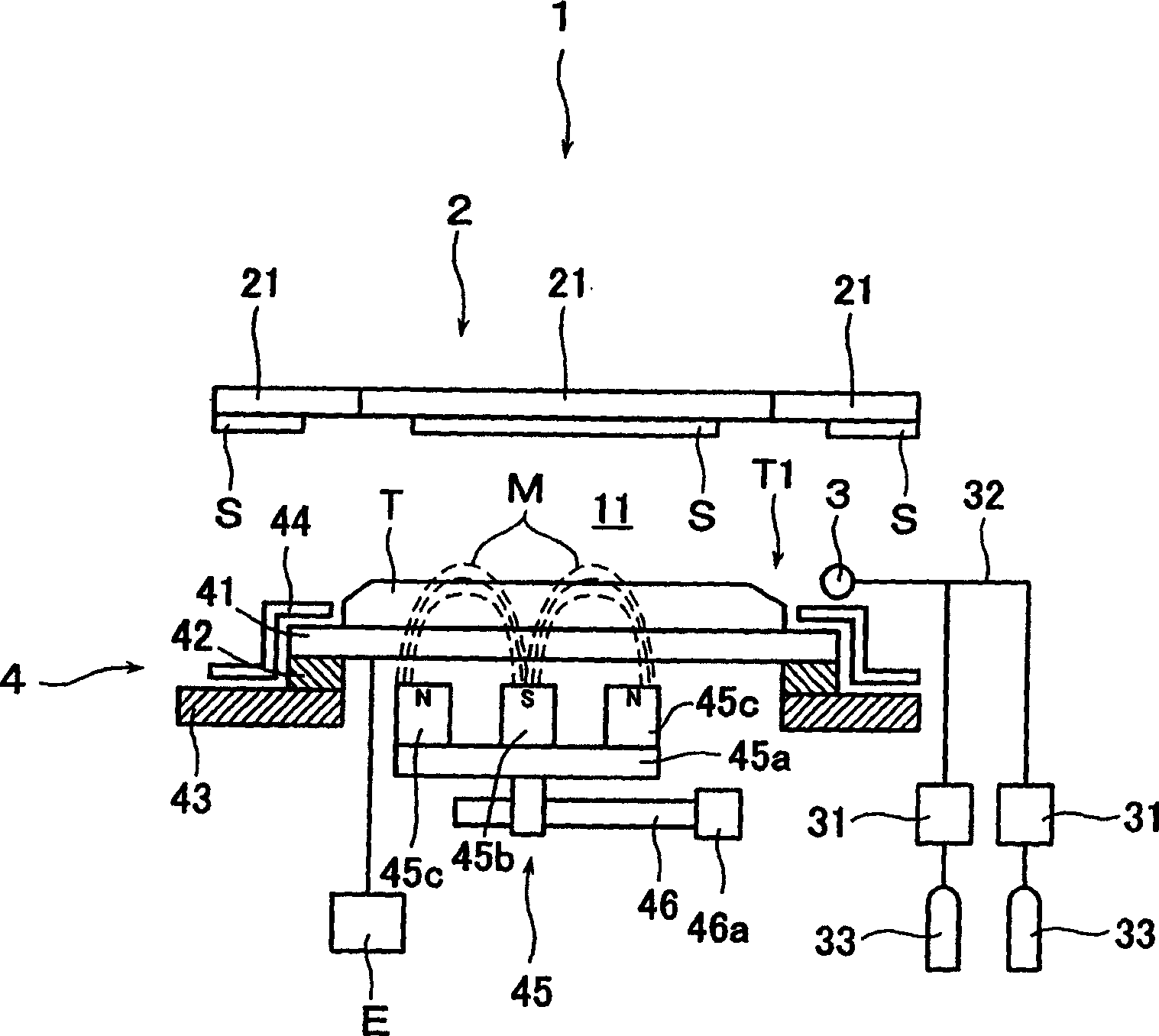

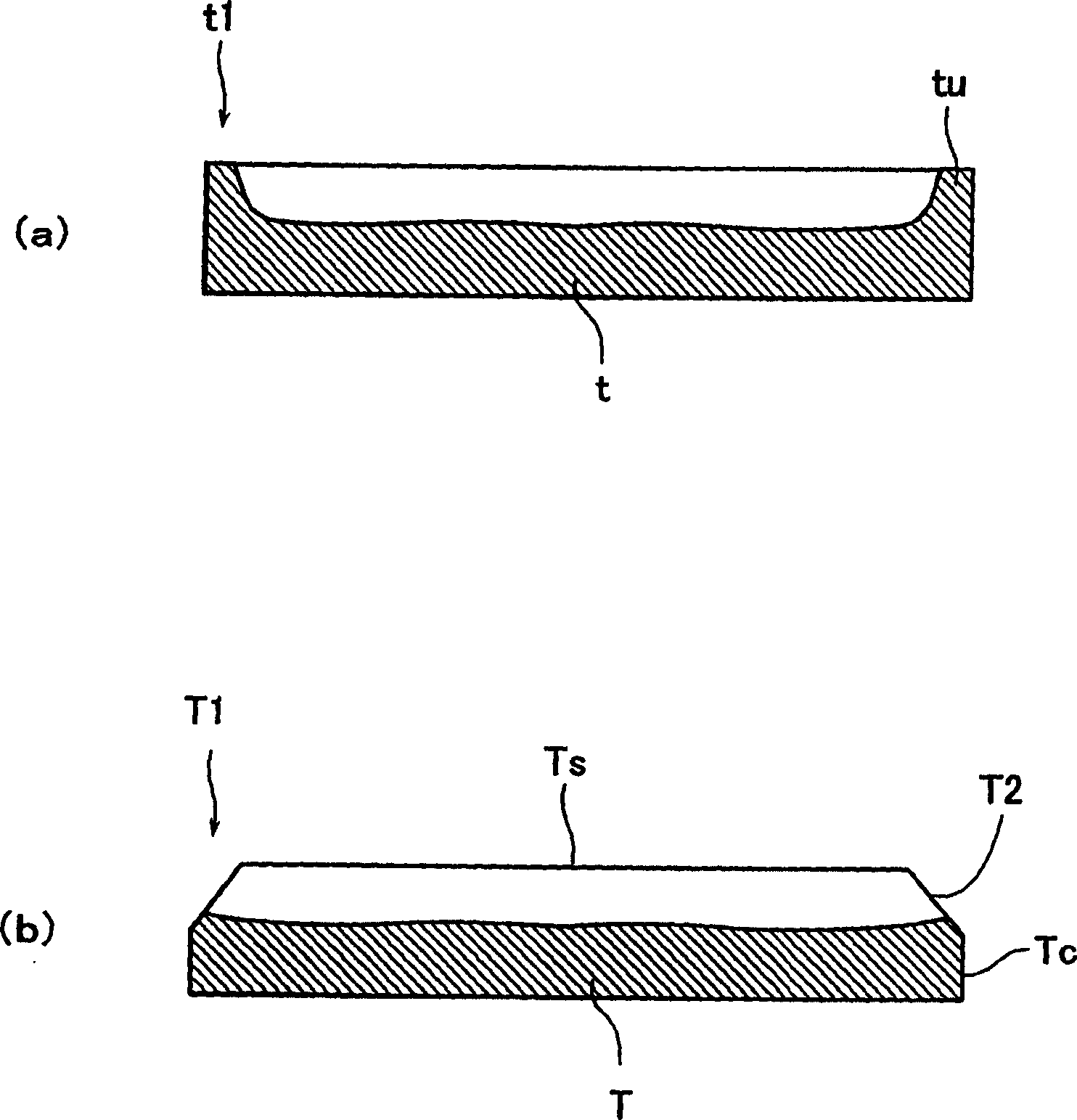

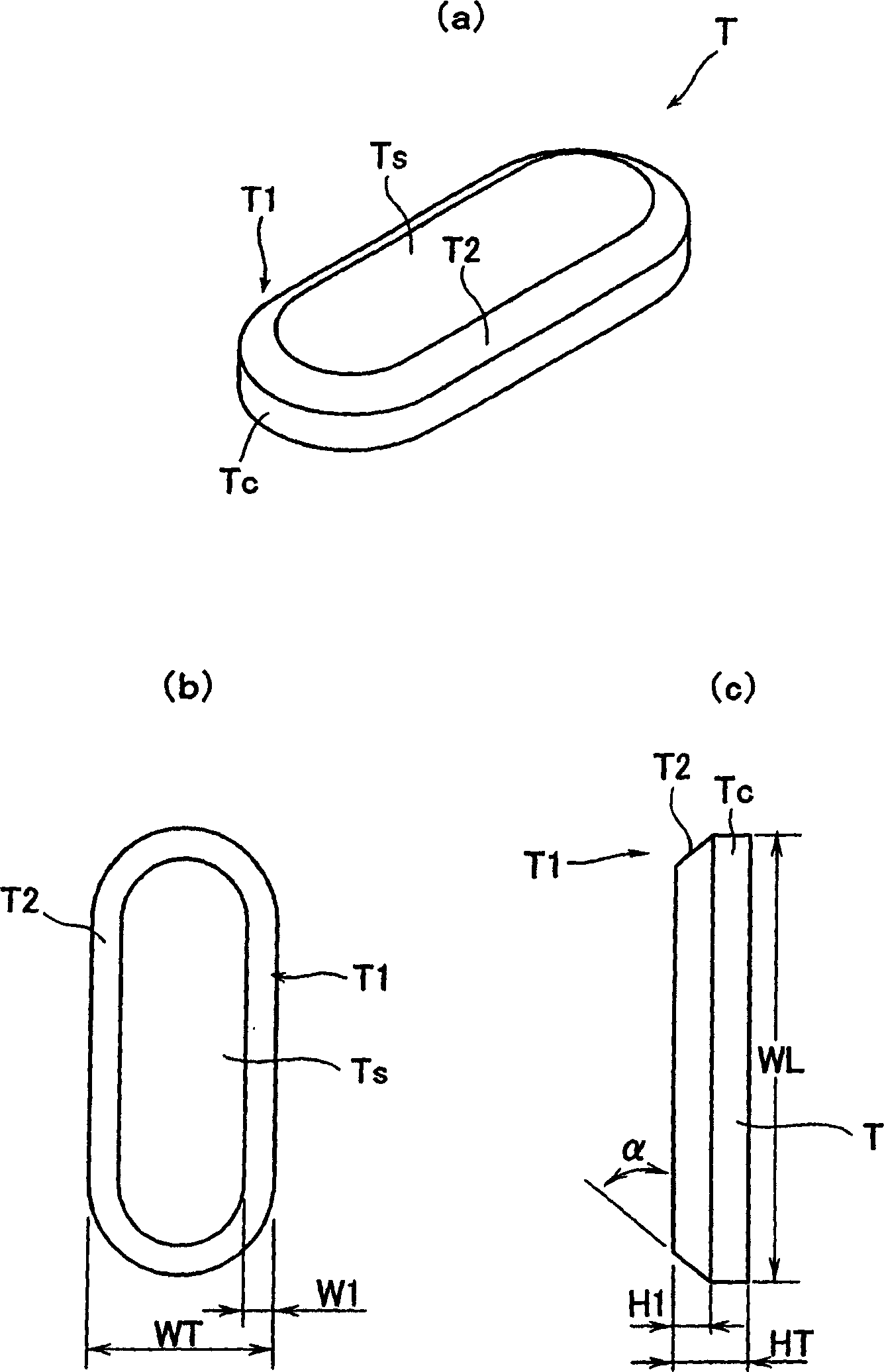

[0042] According to Example 1, the target T was formed from Si into an oblong configuration with a major axis WL (300 mm), a minor axis WT (125 mm) and a height HT (10 mm) by using a known method. Then a bevel, ie a sloped surface T2 with a side width W1 (20 mm) and a height H1 (5 mm), is formed on the target and finally attached to the back plate 41 .

[0043] The target T is mounted on the sputtering device 1 , and then the glass substrate S is transferred to a position opposite to the target T by a vacuum transfer device 21 .

[0044] Under sputtering conditions, the pressure in the sputtering chamber 11 is maintained at a vacuum of 0.4 Pa and argon as a sputtering gas and nitrogen as a reactive gas are introduced into the sputtering chamber under the control of a mass flow controller 31 In step 11, a silicon nitride film is continuously deposited on a glass substrate. In this case, the distance between the target T and the glass substrate was set to 90 mm. Figure 5 Line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com