Silver halide color photosensitive material

A technology of photosensitive materials and color photography, which is applied in the direction of photosensitive materials, optics, and color reduction processing technology, and can solve problems such as insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

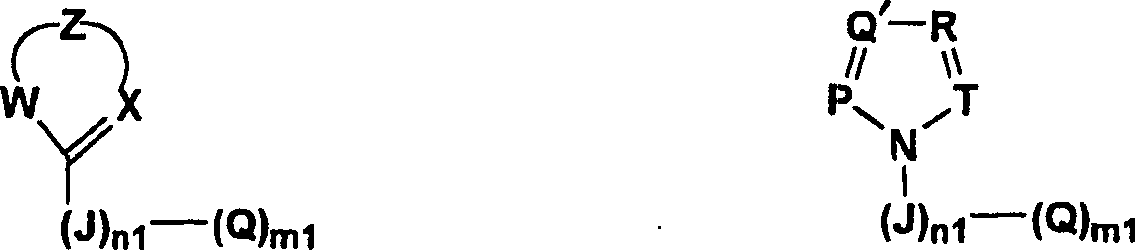

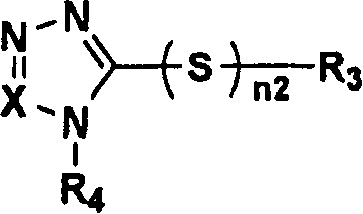

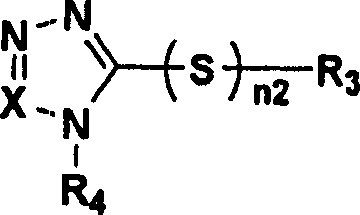

Method used

Image

Examples

Synthetic example

[0141] The synthetic method of exemplary compound 1-1

[0142] Add 4.5 g of 1-(4-carboxyphenyl)-tetrazole to 20 ml of methanol, and add 5 ml of concentrated ammonia to dissolve it completely. Then 2 ml of 35% hydrogen peroxide was added and stirred at room temperature for 12 hours. After adding 1 mol / L hydrochloric acid to make it acidic, the precipitated crystals were filtered and recrystallized from methanol to obtain 3.7 g of Illustrative Compound I-1 (yield 96%).

[0143] Furthermore, in the silver halide color photographic photosensitive material of the present invention, it is preferable that at least one inhibitor among the above inhibitors is a compound represented by the aforementioned general formula (1).

[0144] In the aforementioned general formula (1), X is N or CR', and R' is a hydrogen atom, a substituted or unsubstituted alkyl group or a substituted or unsubstituted aryl group. R 3 and R 4 hydrogen atom, alkyl, alkenyl, alkynyl, aryl or heterocyclic group,...

Embodiment 1

[0295]

[0296] [Preparation of Tabular Silver Halide Emulsion Em-1]

[0297] (Preparation of Tabular Seed Emulsion 1)

[0298] Plate-shaped seed emulsion 1 was prepared through the following procedure.

[0299] [nucleation process]

[0300] In the reaction vessel, 28.3 L of an aqueous solution containing 162.8 g of low-molecular-weight gelatin (average molecular weight: 15,000) and 23.6 g of potassium bromide was kept at 15°C while stirring at a high speed using a mixing and stirring device described in JP-A-62-160128 , while using 0.5 mol / L sulfuric acid, adjust the pH to 1.90. Then, the following S-01 solution and the following X-01 solution were added at a constant flow rate by the double nozzle method within 1 minute, and when nucleation proceeded, the following G-01 solution was added.

[0301] S-01 liquid: 205.7ml of 1.25 mol / L silver nitrate aqueous solution

[0302] X-01 liquid: 205.7ml of 1.25 mol / L potassium bromide aqueous solution

[0303] G-01 liquid: 2921...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com