Method and equipment for producing edible vinegar

A technology of edible vinegar and raw materials, which is applied in the field of food condiments, can solve the problems of difficult preservation, unstable quality, uneven heat, etc., and achieve the effects of improving heat utilization rate, increasing per capita output, and saving construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] 1. Material selection, weigh 100 kg of sorghum wheat bran, 100 kg of Daqu, 10 kg of glucoamylase, 1.5 kg of dry yeast, 0.5 kg of rice bran, 20 kg of vinegar grains, 500 kg of water, and 100 kg of water. 1 / 1000 of finished vinegar;

[0034] 2. Crushing;

[0035] 3. Moisturizing material;

[0036] 4, steaming material, (the above process is basically the same as the prior art);

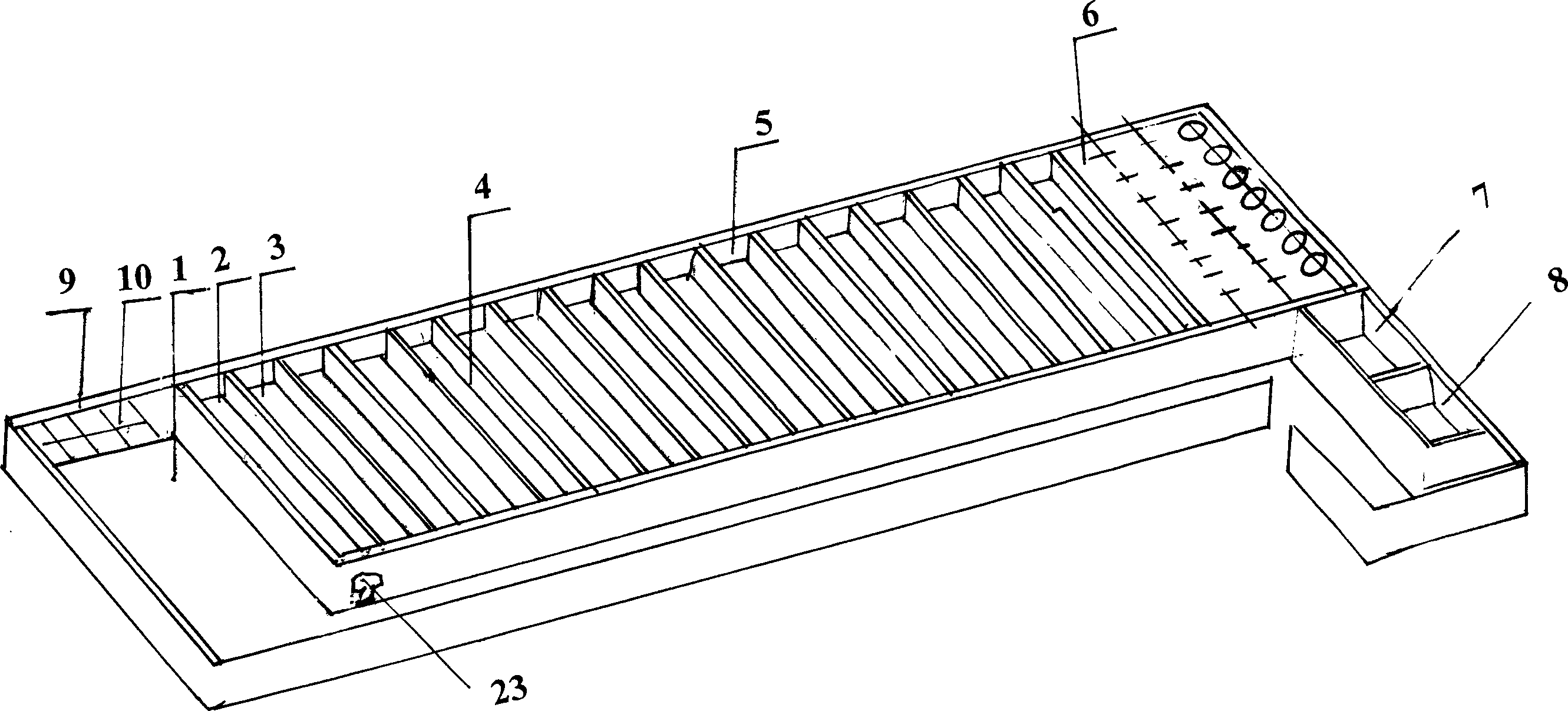

[0037] 5. Discharging, cooling, and alcohol fermentation; there is a ventilation door and a high-power blower in the steaming tank 2. After the raw materials are steamed, close the valve, open the air door, and use the blower to cool down; when the temperature drops below 30 degrees , stop the blower 23, divide Daqu and fermented dry yeast, glucoamylase into 3 parts, sprinkle 1 part evenly on the material, move the mixer into the plank between the steaming material tank 2 and the alcoholic grain fermentation tank 4 , stir one-third of the material directly into the alcohol fermented grain ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com