Patents

Literature

31results about How to "Improve vinegar yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for brewing pure grain vinegar

InactiveCN105255701APromote decompositionLow priceVinegar preparationMedicinal herbsIntermediate stage

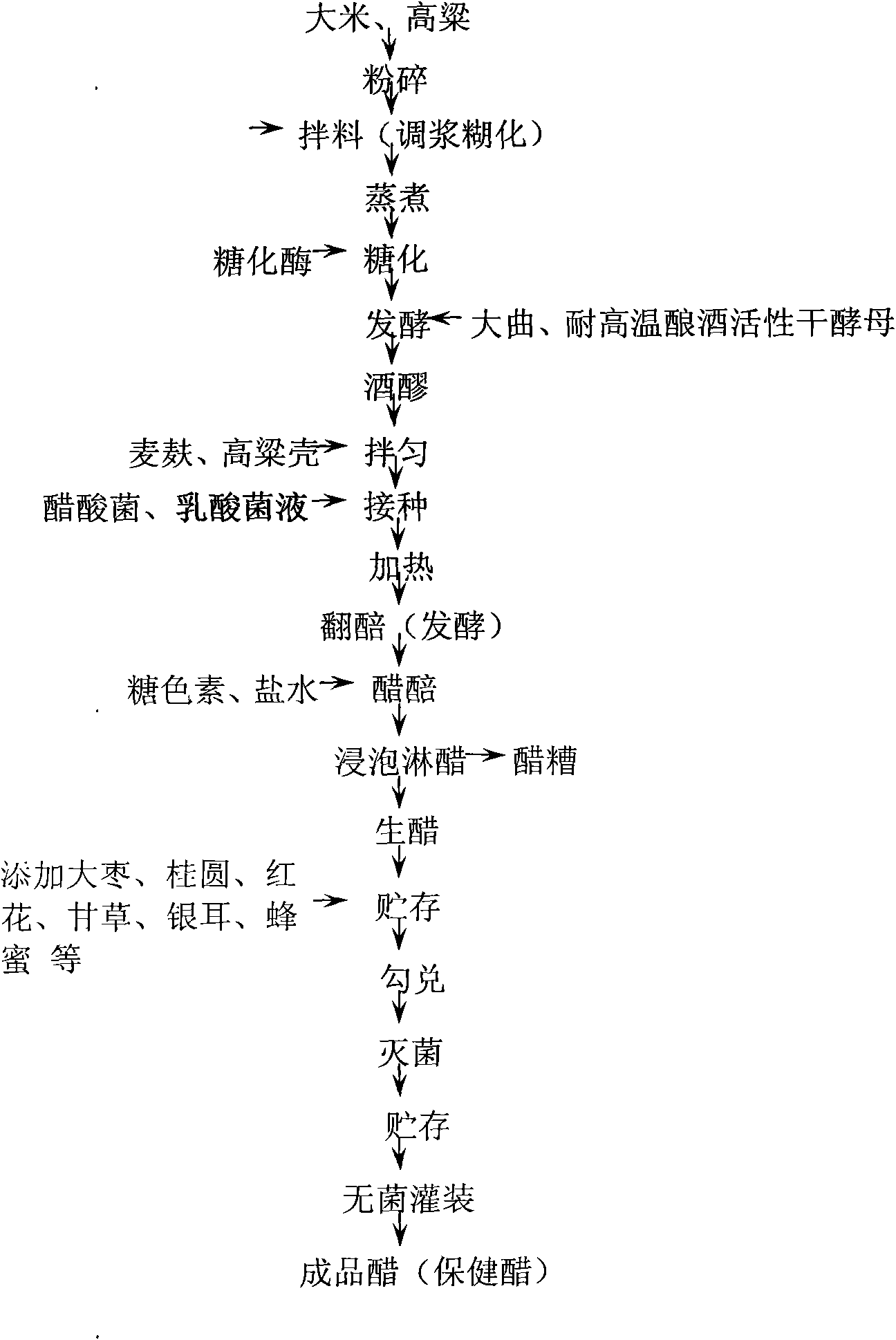

A method for brewing pure grain vinegar includes the steps that firstly, material mixing is performed, wherein sorghum, bran and rice bran are mixed, and Chinese medicinal herbs are added into the mixture; secondly, material steaming is performed, wherein the materials mixed in the first step are steamed at the temperature of 100-115 DEG C; thirdly, inoculation is performed, wherein the steamed materials are inoculated after being smashed, and the steamed materials and expanding leaven are evenly stirred and inoculated according to the weight ratio of 20:3; fourthly, fermentation is performed, wherein the inoculated materials are placed into a pot, compacted and fermented, the materials are sealed at the early stage of fermentation, the temperature is raised day by day in the middle stage, and the temperature is lowered day by day in the later stage; fifthly, vinegar pouring is performed, wherein the materials are sprayed with vinegar and soaked for 12-13 hours through white vinegar blank fermented in the fourth step, smoked vinegar formed by smoking the vinegar and water according to the weight ratio of 5:2:20, and vinegar liquid drops through a filter screen; sixthly, the vinegar liquid is sterilized; seventhly, the vinegar liquid is filtered; eighthly, the vinegar is stored under low-temperature and dry conditions. The vinegar yield is high, and the finished vinegar is good in taste, color and flavor.

Owner:ZIZHOU COUNTY RUIZHENG BREWING CO LTD

Method for preparing gamma-aminobutyric acid rich vinegar

ActiveCN101603000AMild tasteInhibit bacteriaMicroorganism based processesVinegar preparationGamma-Aminobutyric acidSodium Glutamate

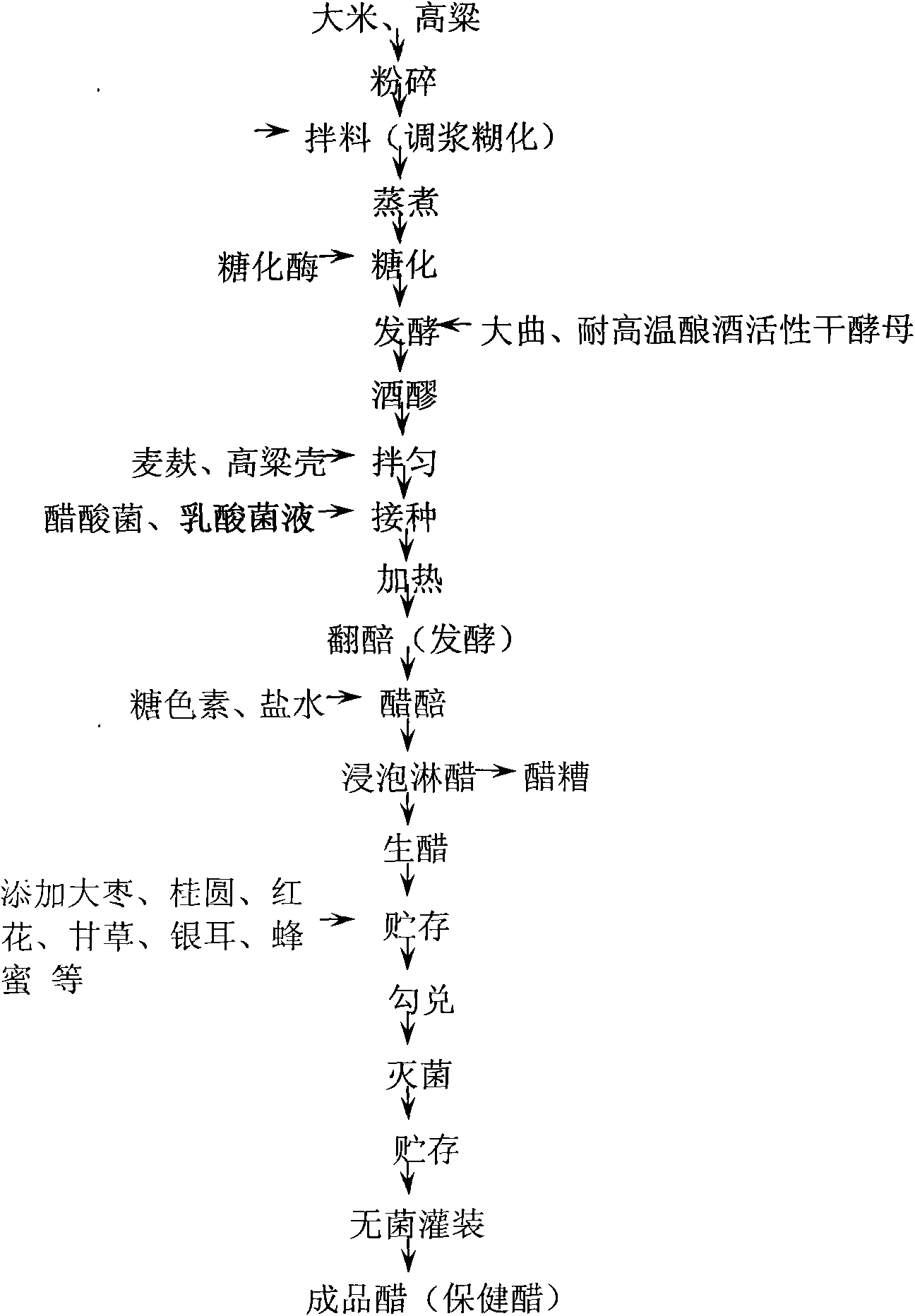

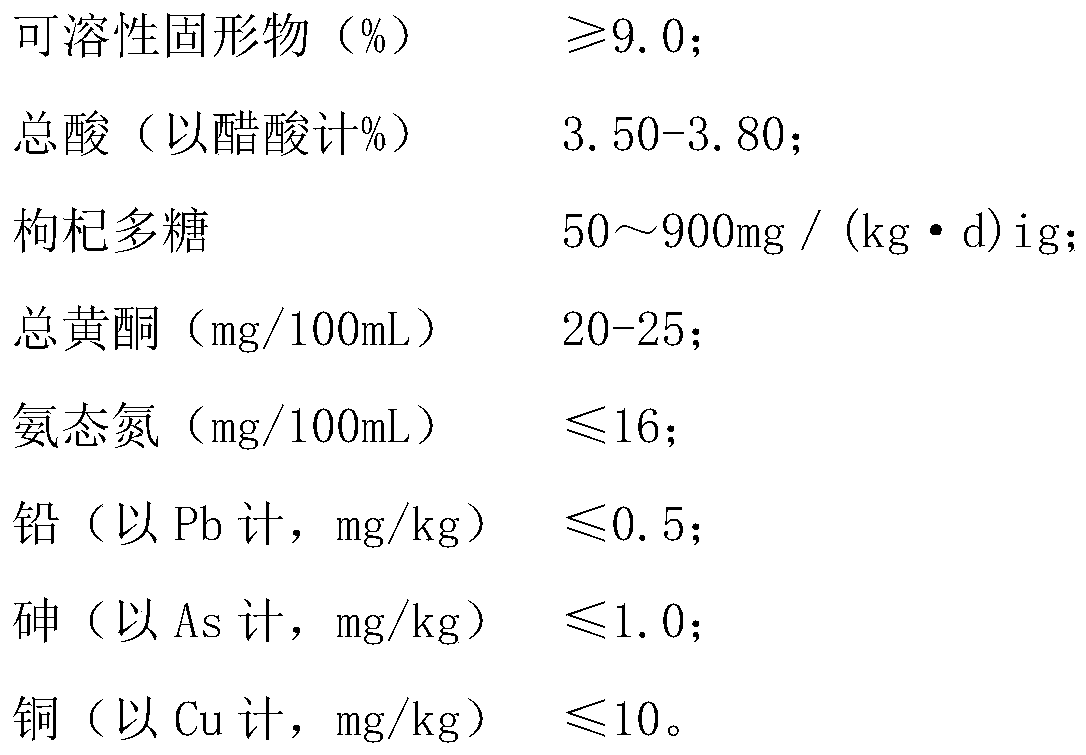

The invention discloses a method for preparing gamma-aminobutyric acid rich vinegar, belongs to the technical field of seasoning brewing engineering, and particularly relates to the technical field of edible vinegar production. The method for preparing health-care vinegar comprises processes of liquefaction, saccharification, yeast addition, yeast fermentation and acetic fermentation; and lactobacillus brevis and acetic acid bacteria are added in the acetic fermentation process, the lactobacillus brevis is added before the acetic acid bacteria is added or synchronously added with the acetic acid bacteria, and sodium glutamate is added when the lactobacillus brevis is added. The product of the invention is soft when entering the mouth and acid after tasting, has no peculiar smell, has clear vinegar liquid and gloss, and is amber edible vinegar, or the edible vinegar with health-care functions of reducing blood pressure, promoting sleep, reducing serum cholesterol, delaying senility, and the like.

Owner:TIANDI YIHAO BEVERAGE JIANGMEN CITY

Liquor mash preparation method based on multi-enzyme system and application of method in vinegar brewing

ActiveCN107034087AAlcohol conversion rate is highImprove conversion rateMicroorganism based processesAlcoholic beverage preparationCellulosePullulanase

The invention discloses a liquor mash preparation method based on a multi-enzyme system and application of the method in vinegar brewing. Sticky rice powder paste combines with a traditional yeast phase by utilizing multiple biological enzyme preparations such as alpha-amylase, pullulanase, saccharifying enzyme, cellulose enzyme, protease and lipase and a traditional yeast, enzymolysis is performed by adopting step-by-step adding method, and then liquor mash is prepared through alcohol fermentation. By adopting the method, raw and auxiliary material utilization rate is further improved based on liquid saccharification, the alcohol conversion rate is improved, the production cost is reduced, and meanwhile a product flavor obtained by adopting a traditional process is retained.

Owner:JIANGSU HENGSHUN VINEGAR IND

Sea-buckthorn fruit vinegar and preparation method thereof

InactiveCN104164352AMeeting the needs of special populationsFull expression of unique flavorMicroorganism based processesVinegar preparationAcetic acidSlurry

The invention discloses a method for preparing sea-buckthorn fruit vinegar. The method comprises the following steps: S1. selection, namely selecting sea buckthorn fruits and removing impurities from sea buckthorn fruits; S2. washing, namely washing the sea buckthorn fruits cleanly; S3. beating, namely beating the washed sea buckthorn fruits; S4. concentration, namely concentrating the sea buckthorn fruit slurry till the content of solids is 62-68 percent; S5. adjustment of sugar degree and pH value, namely adjusting the total sugar degree to 8-16 percent and the pH value to 3.5-4.5; S6. alcoholic fermentation, namely adding secondary spread yeast fermentation liquor to the sea buckthorn fruit slurry and carrying out alcoholic fermentation to obtain fermented mash; S7. acetic acid fermentation, namely adding brewing-mass to the fermented mass, inoculating secondary spread yeast fermenting liquor and then carrying out acetic acid solid-state fermentation; and S8. drenching of vinegar, namely leaching according to a three-circulation drenching method. The sea-buckthorn fruit vinegar disclosed by the invention has good nutrient contents, smooth and natural taste, bright color and stable quality; the method for preparing sea-buckthorn fruit vinegar has the advantages of short fermentation time, high vinegar yield and good flavor of fruit vinegar prepared according to the method, and is suitable for large-scale industrial production.

Owner:小金金山沙棘饮料食品厂 +1

Method for biological strengthening of vinegar by using marine-derived bacillus licheniformis

ActiveCN107418909AAdd flavorImprove qualityBacteriaMicroorganism based processesBacillus licheniformisAcetic acid

The invention discloses a method for biological strengthening of vinegar by using marine-derived bacillus licheniformis, and belongs to the technical field of food brewing. According to the method, bacillus licheniformis (B. licheniformis) with CCTCC NO: M 2017209 is selected from marine environment, and the B. licheniformis can grow at 65 DEG C and has a high amylase production capacity. According to the method, the B. licheniformis is made into B. licheniformis powder for enhancing fermentation of acetic acid of the vinegar, and the method has the advantages of improving the utilization ratio of raw materials, improving the product flavor of the vinegar and improving the quality of the vinegar.

Owner:JIANGNAN UNIV

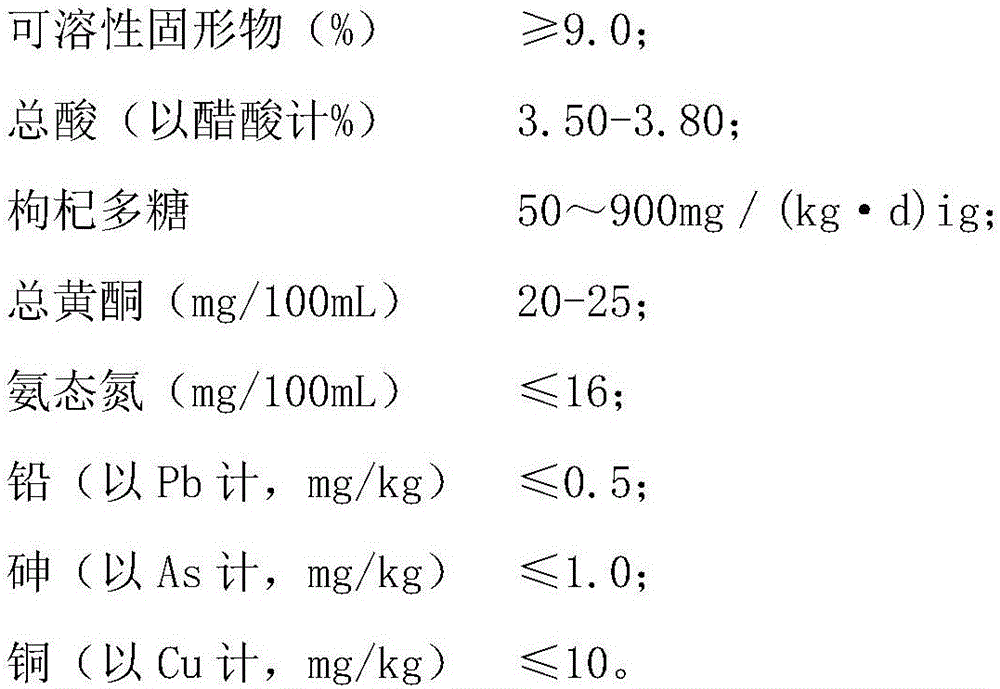

Liquid submerged fermentation technique of Chinese wolfberry/licorice root/apple health-care vinegar

ActiveCN106367284AQuality improvementShort fermentation cycleDigestive systemVinegar preparationNutritive valuesAcetic acid

The invention provides a liquid submerged fermentation technique of Chinese wolfberry / licorice root / apple health-care vinegar. The technique comprises the following steps: (1) preparation of apple raw juice; (2) sugar blending; (3) yeast primary fermentation; (4) liquid submerged acetic fermentation; (5) rough filtration, afterripening; (6) preparation of Chinese wolfberry / licorice root leaching solution; and (7) blending, sterilization and filling. The technique organically combines the health-care fruit vinegar with the particular Chinese wolfberry and licorice root in Ningxia Province and utilizes the liquid submerged fermentation process, thereby greatly shortening the fermentation period. The prepared Chinese wolfberry / licorice root / apple health-care vinegar has the advantages of high nutritive value, fresh and unique taste, clear appearance, favorable color and small pungency of acetic acid.

Owner:宁夏强尔萨生物科技有限公司

Vinegar making method

Disclosed is a vinegar making method. The making method includes the following steps: mixing bran, pea powder, mung bean powder and wheat flour, adding water and stirring uniformly, and making brick-shaped yeast billet by the mixture with a yeast pressing die, grinding and sifting yeast to obtain yeast powder; soaking sorghum and rice separately in water, and steaming the material; putting steamed sorghum and rice into a fermentation tank, adding water and stirring, then adding the yeast powder, uniformly mixing and fermenting to obtain the fermented grains; putting bran, rice bran and fermented grains into a brewing tank, mixing evenly, and then adding acetic acid bacteria to the mixed material, stirring evenly, sealing the brewing tank, overturning 17-20 times to obtain aged vinegar grains; covering the vinegar grains with a layer of salt on the surface, compacting the material in the brewing tank, sealing the brewing tank, overturning once every 18 to 22 days, pouring vinegar and sterilizing to obtain vinegar after 3-6 months. The vinegar product prepared by the method has the advantages of good color, fragrance and taste, which increases the safety of food, and the yeast billet is convenient to store and transport, and is more convenient to use.

Owner:连云港市馨祥酿造有限公司

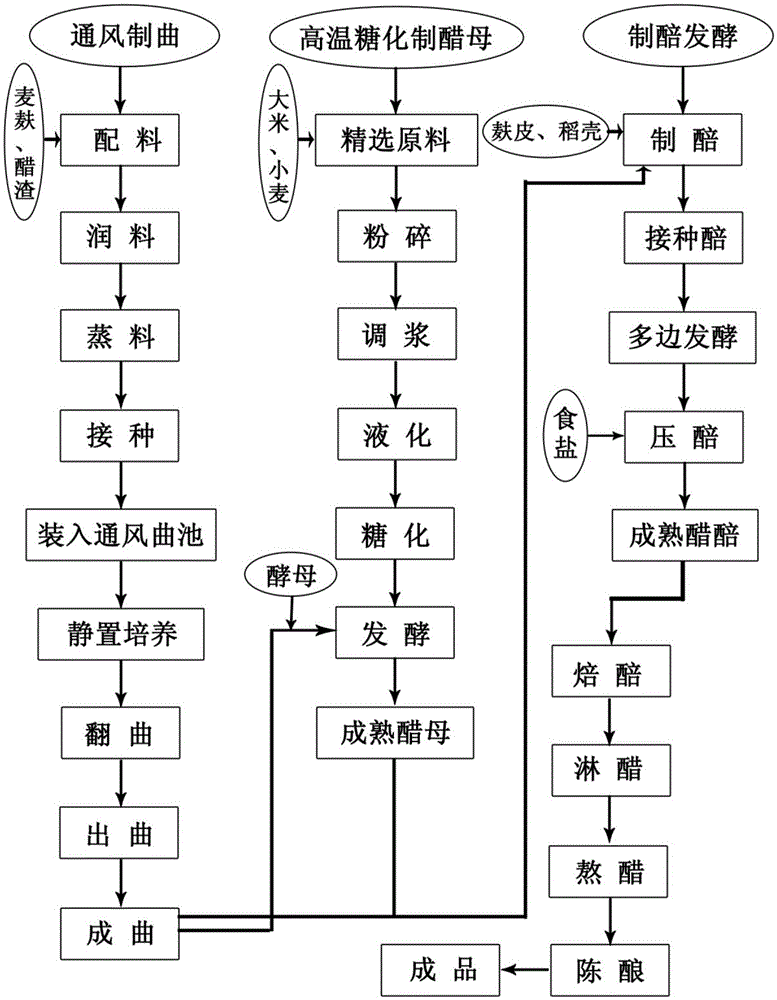

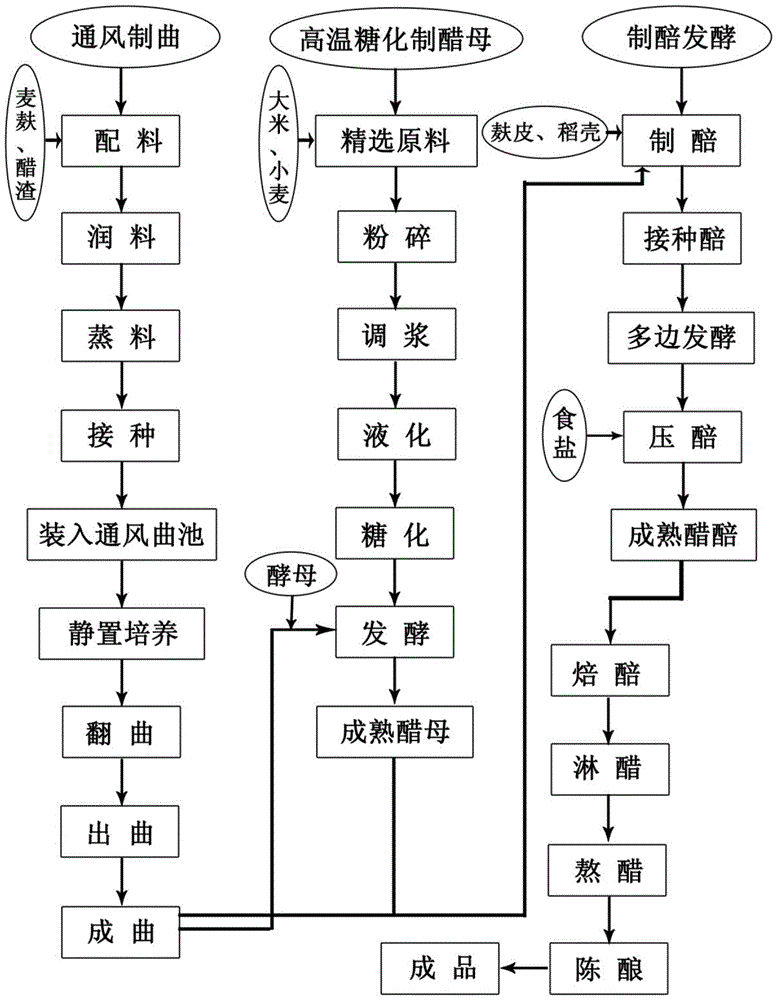

Novel production process of traditional Ningxia Hui vinegar

ActiveCN104789440AOptimize the traditional production processPromote growth and reproductionVinegar preparationCooking & bakingEnzyme system

The invention discloses a novel production process of traditional Ningxia Hui vinegar developed based on a traditional process and solves the problems that the current Ningxia Hui vinegar production process is too long in production period and complex in technology, unstable in product quality and low in raw material utilization rate. The traditional production process is modified, namely a thick-layer ventilation starter propagation technology is adopted in the starter propagation; the processes of liquefying at high temperature and saccharifying to manufacture the saccharification mash are adopted to manufacture the yeast; the traditional process of trilateral fermentation of the Ningxia Hui vinegar is kept in the solid state fermentation; a baking and fermenting process is added; a double-set heat spraying circulation method is adopted in the vinegar spraying process; a solar energy is used for aging; an excellent strain with high enzyme activity is used in starter propagation process; a high-activity yeast and various microbe compound starters are adopted for fermenting so as to enrich the microbe enzyme system; a modern biological fermentation technology is combined with the process to substitute the traditional control mode depending on experience; the Ningxia Hui vinegar technological process is systematized, the technological parameter is standardized and a best fermentation process condition is reached so that the product quality is guaranteed.

Owner:宁夏强尔萨生物科技有限公司

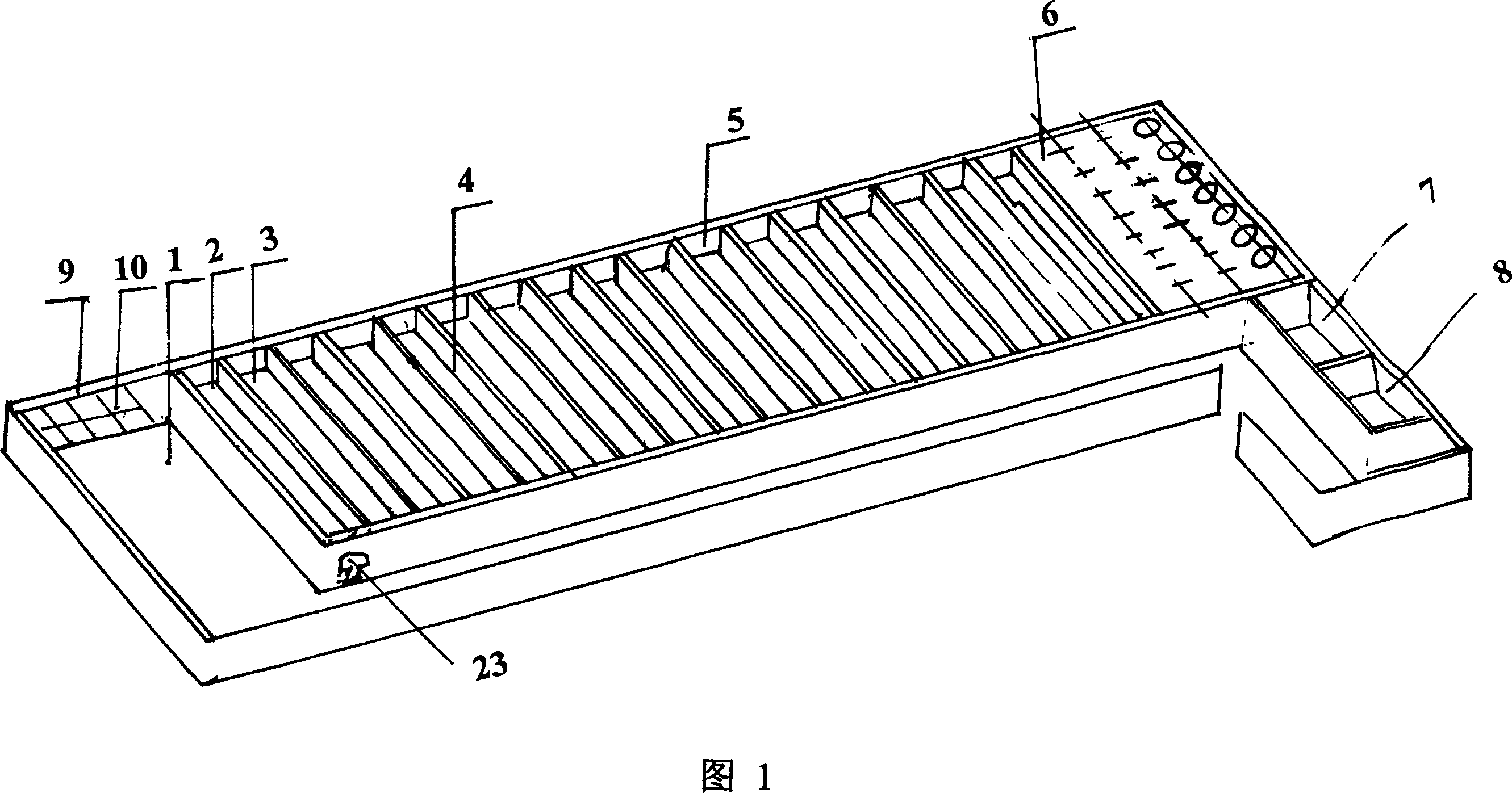

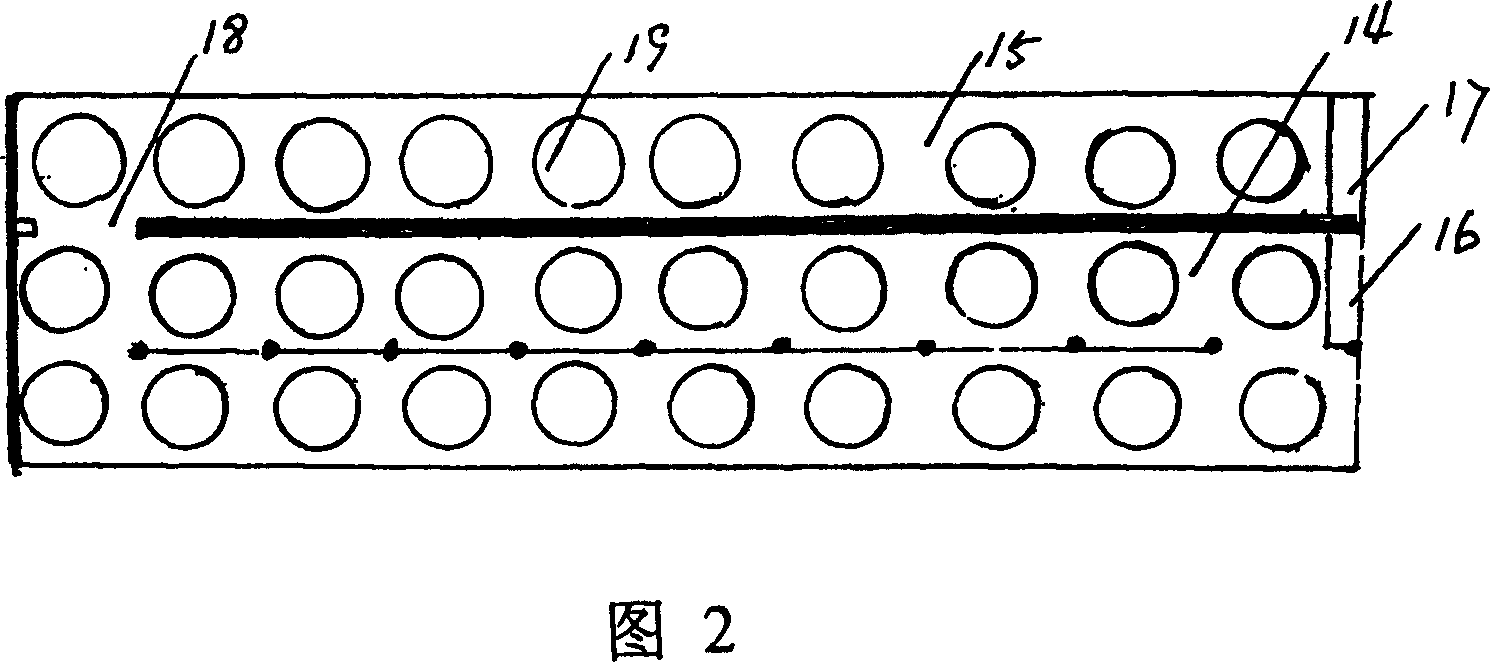

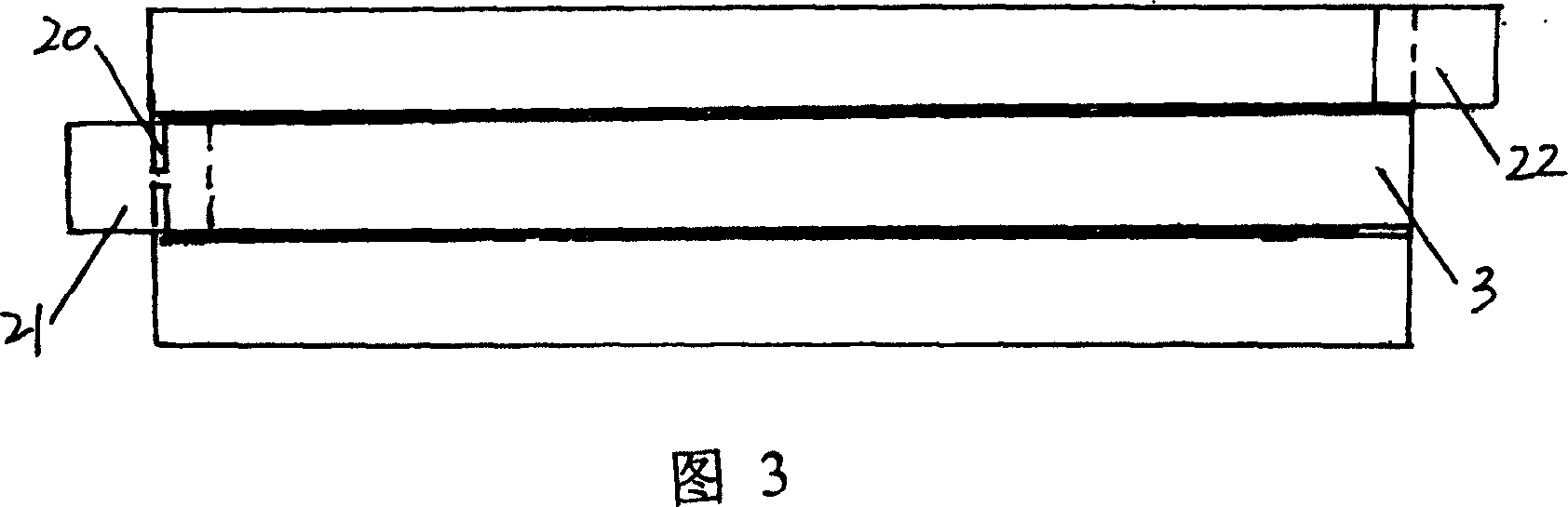

Method and equipment for producing edible vinegar

A process for preparing the edible vinegar with high output rate features that its raw materials include proportionally sorghum grains, wheat bran, yeast, beta-amylase, dried yeast, rice husk, vinegar dregs, edible salt, and sodium benzoate. A novel fire fumigating apparatus for high uniformity of fire fumigating to all jars is also disclosed.

Owner:明克宽

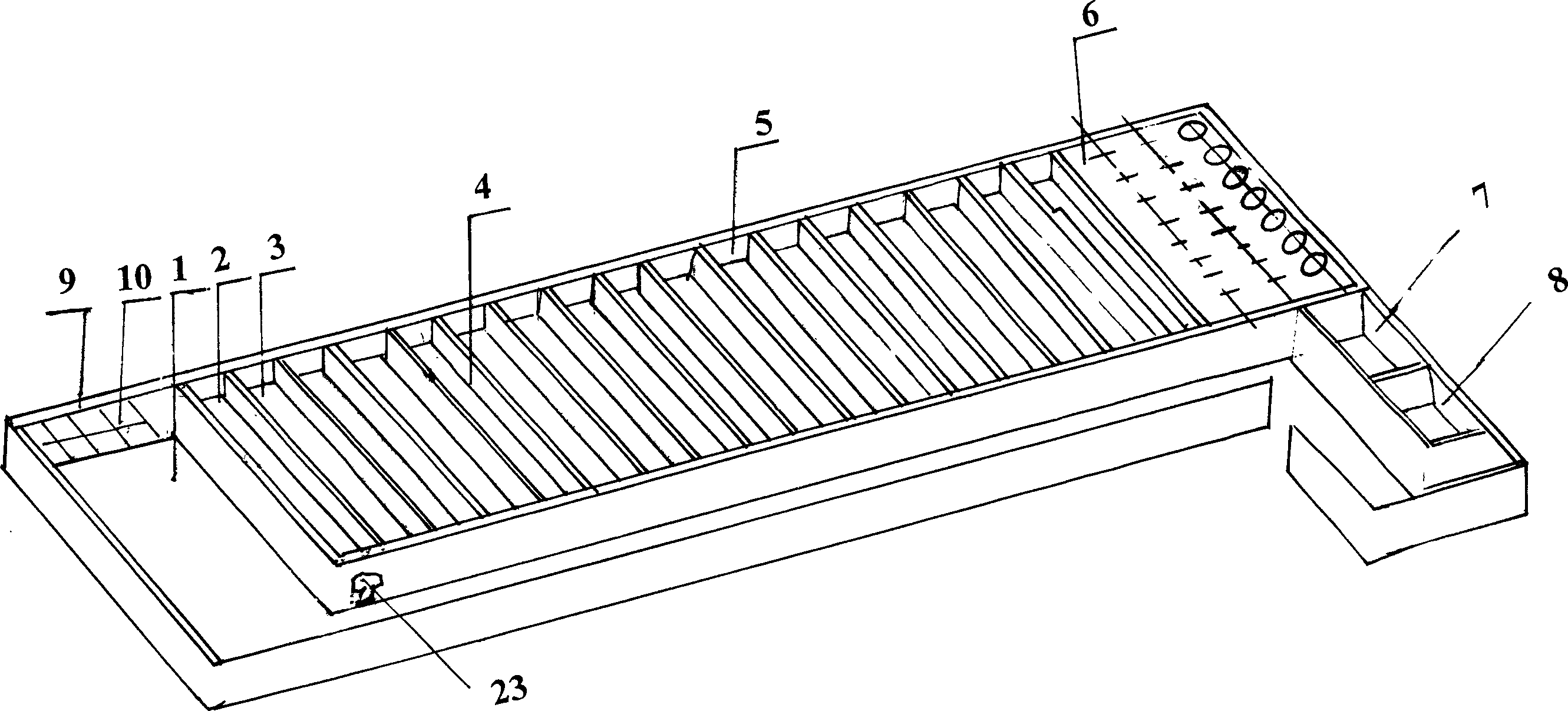

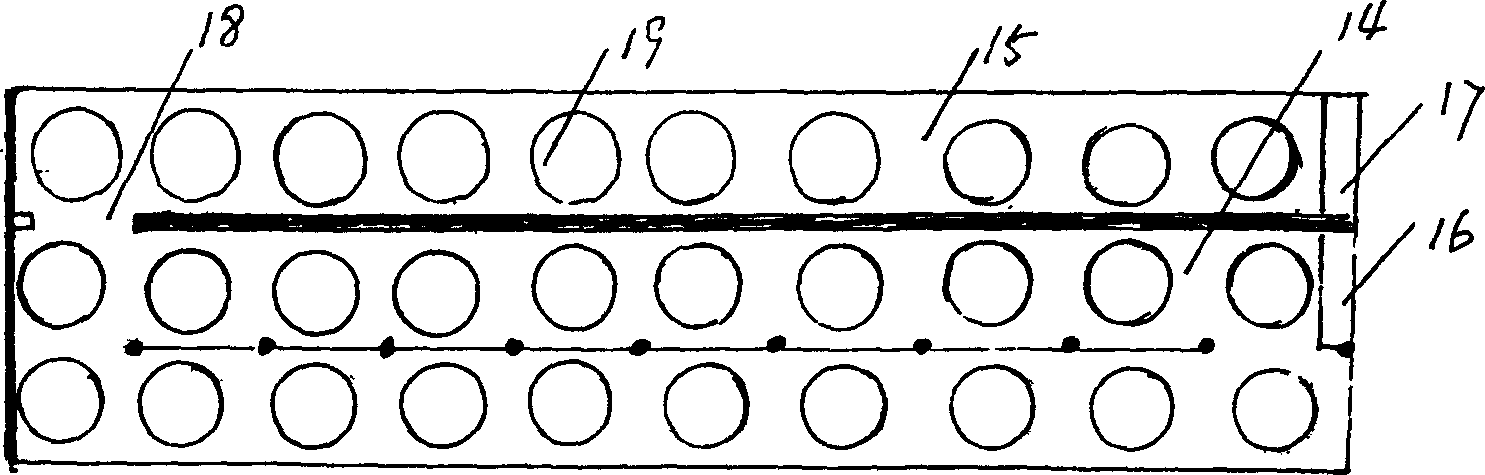

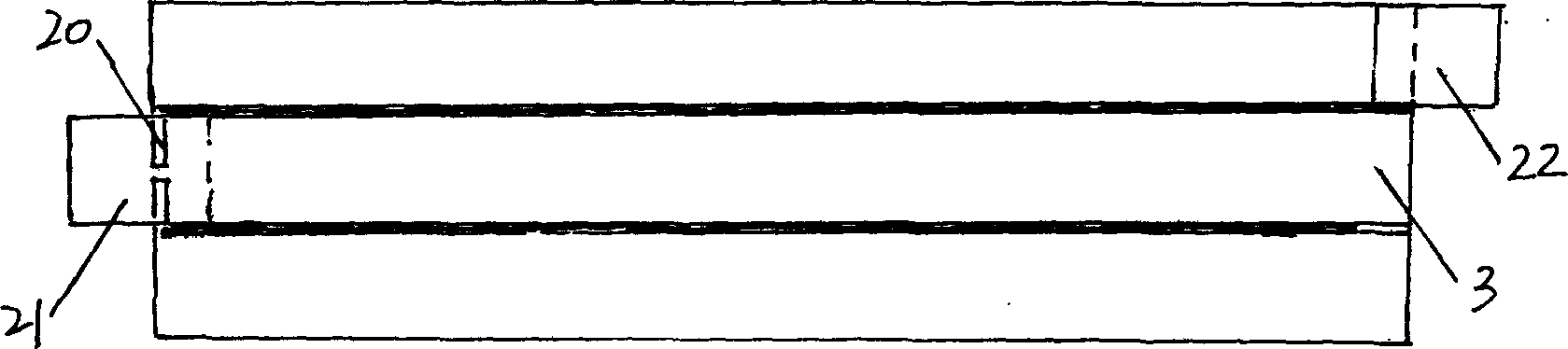

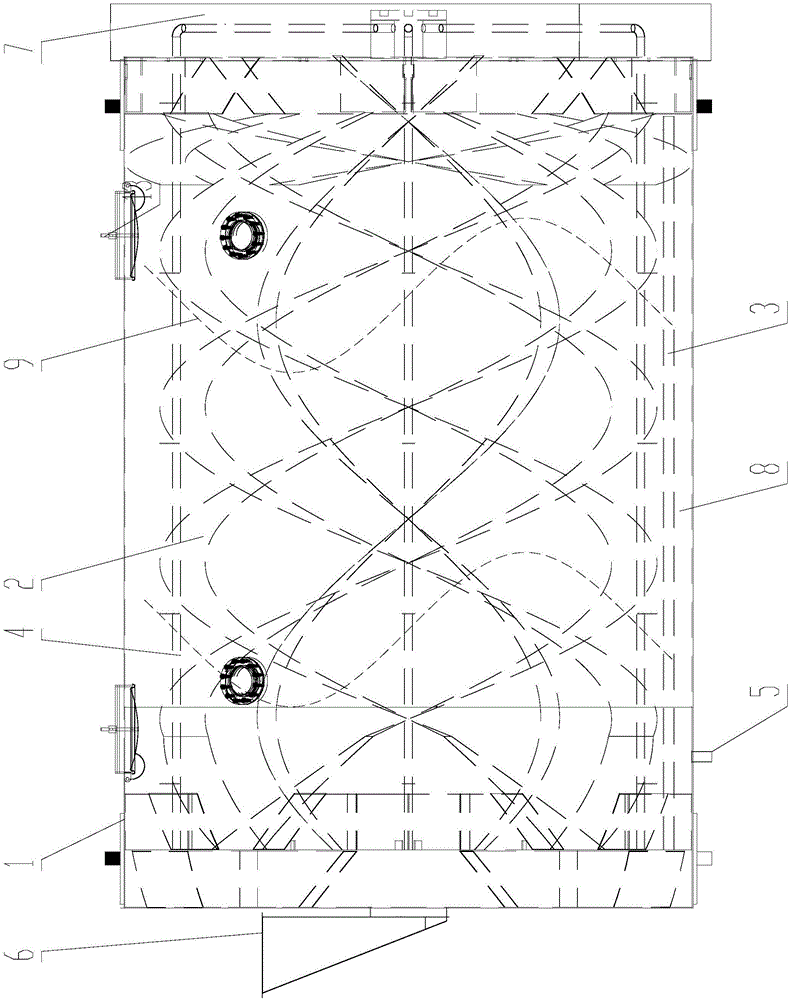

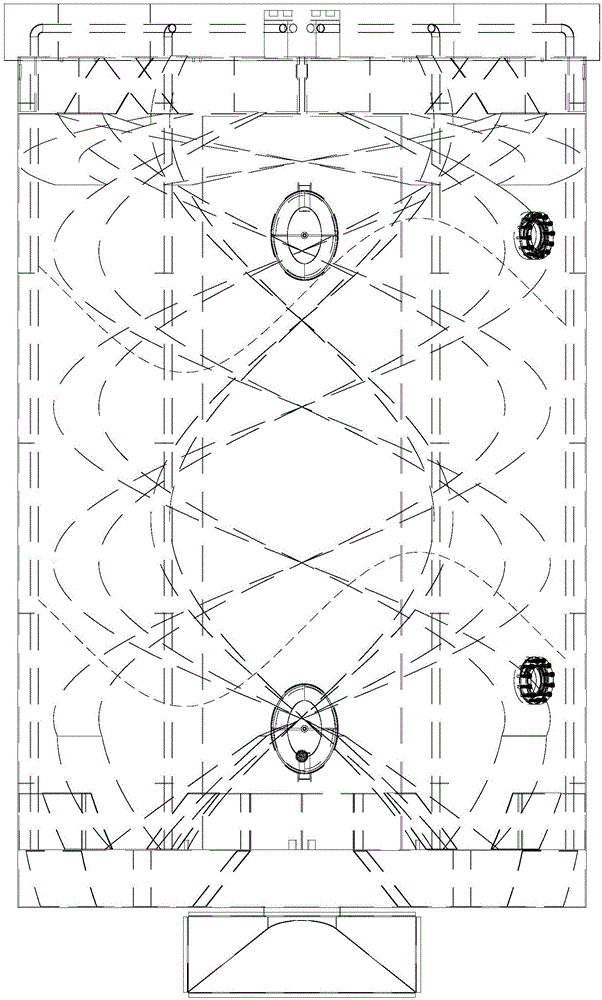

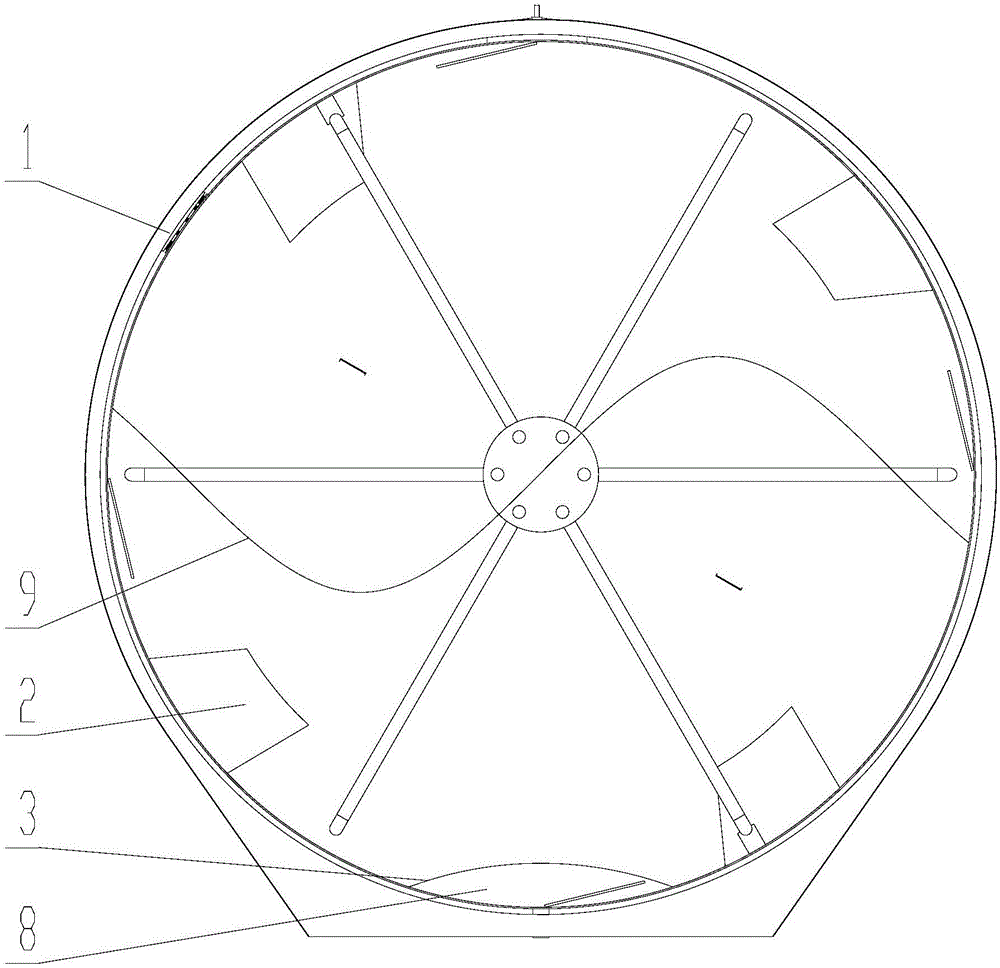

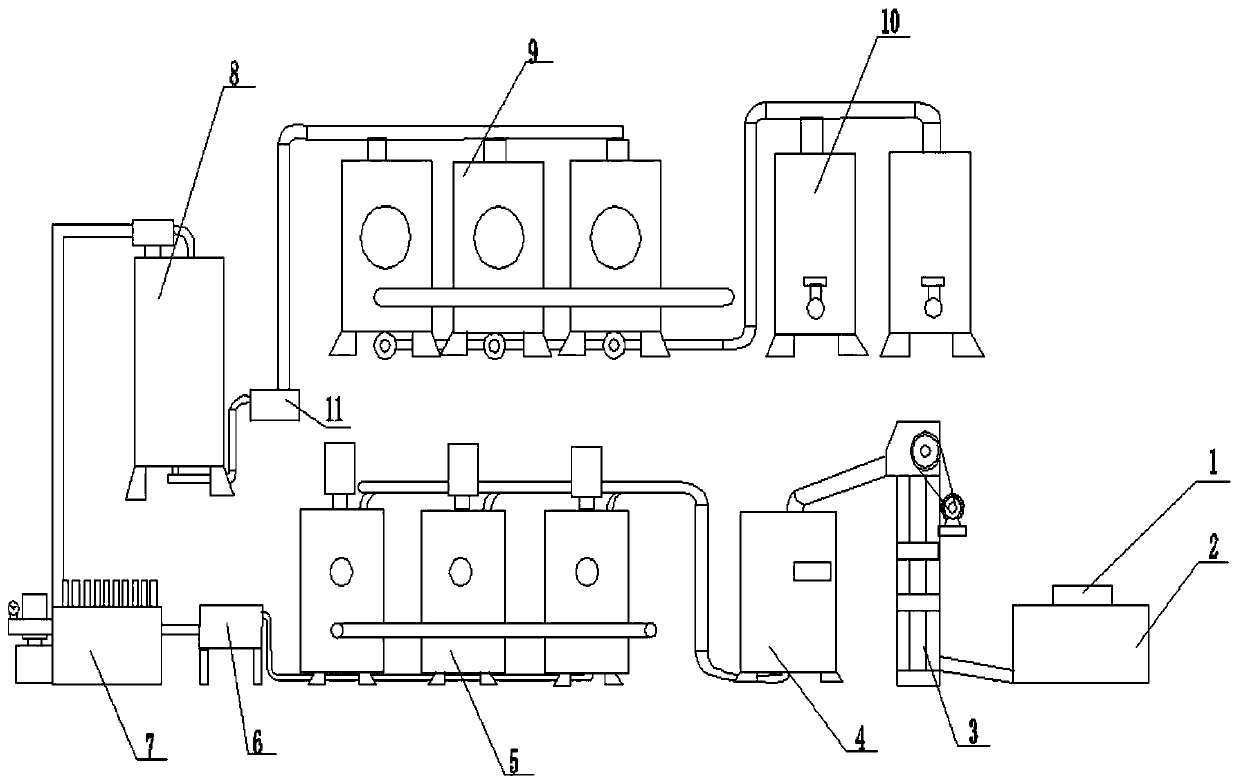

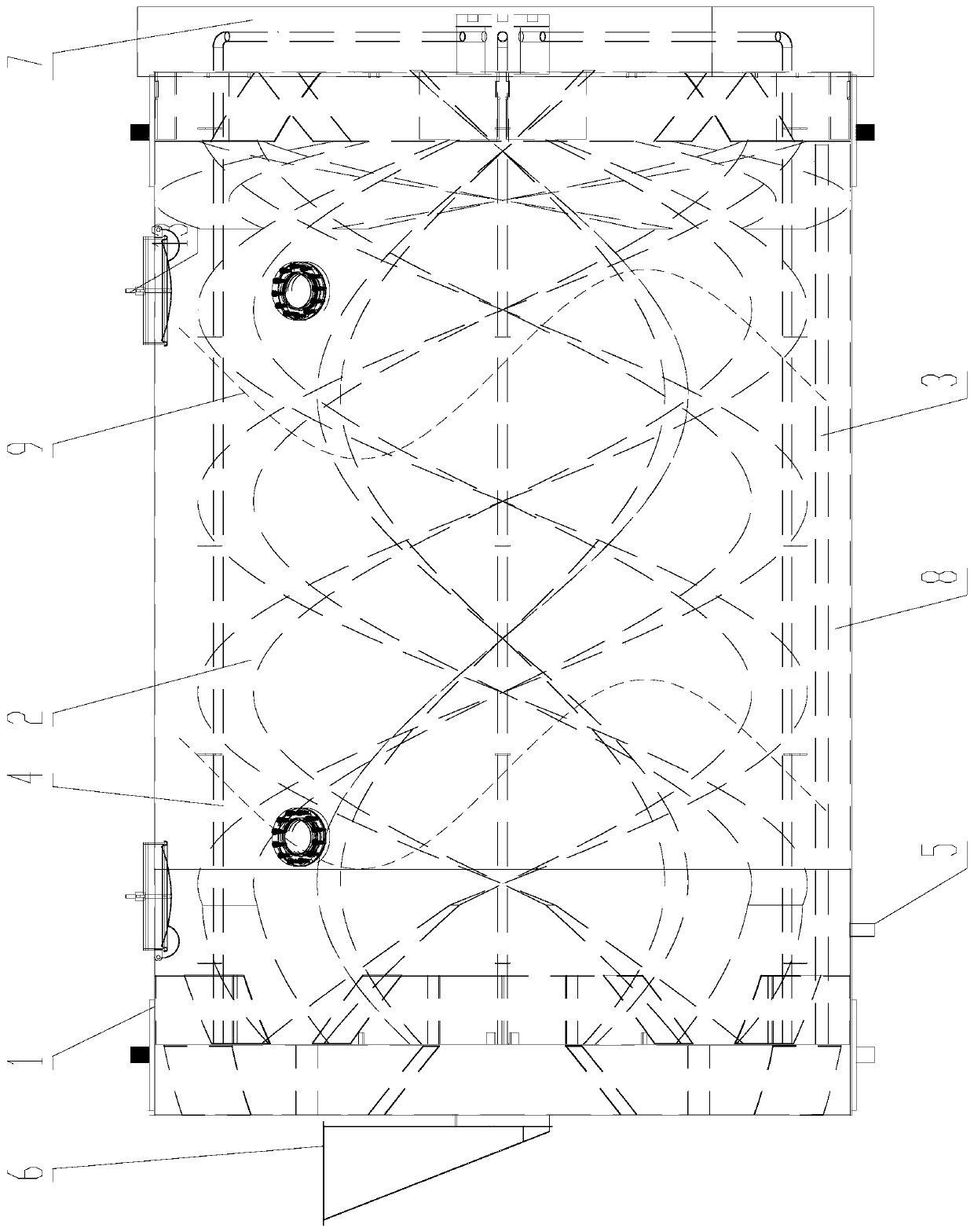

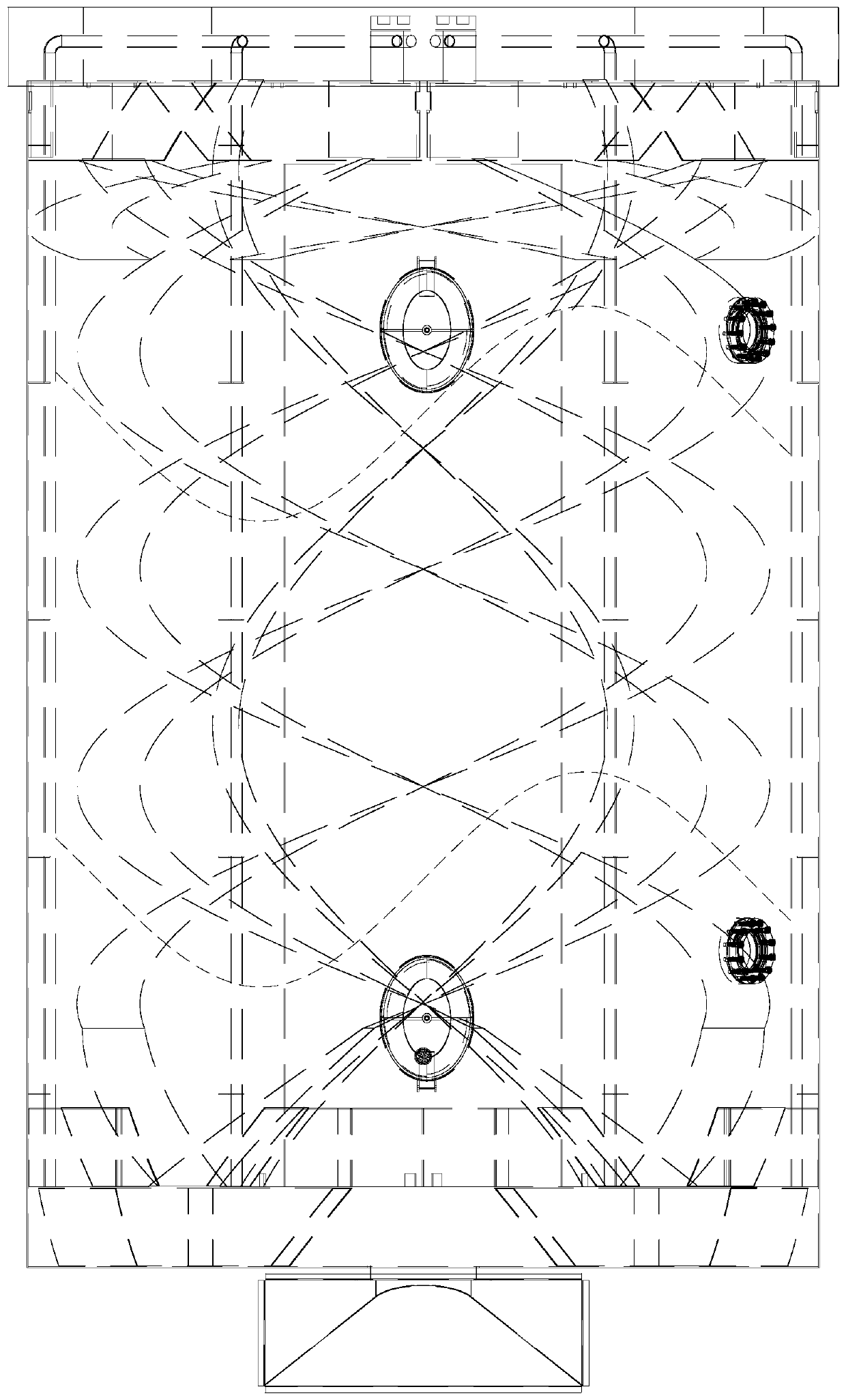

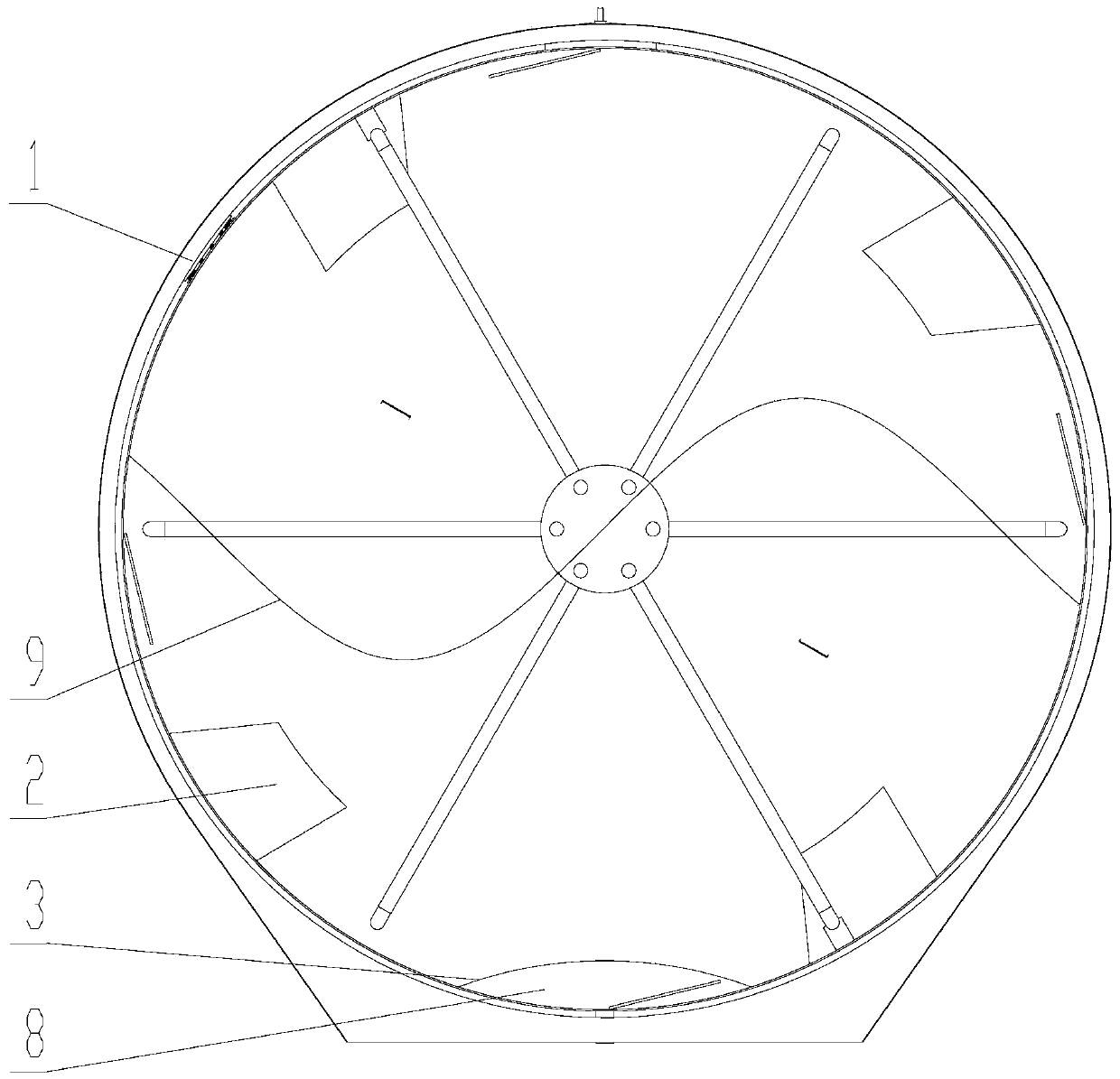

Vinegar solid-state brewing integrative machine

ActiveCN106244413AAchieve multi-functionalityIncrease profitVinegar preparationBiochemical engineeringFood flavor

The invention discloses a vinegar solid-state brewing integrative machine. The vinegar solid-state brewing integrative machine comprises a tank body which is of a horizontal rotary cylinder, spiral material turning strips, a through-long filter plate, spray devices, a ventilation pipe and a liquid outlet pipe, wherein a feed inlet is formed in one end of the tank body, and a discharge port is formed in the other end of the tank body, the spiral material turning strips are arranged on the inner wall of the tank body and between the feed inlet and the discharge port, and the ventilation pipe is connected to the tank body; for the fermentation site of the tank body, the through-long filter plate is arranged above the inner bottom of the tank body, and a cavity is formed between the through-long filter plate and the bottom of the tank body, the spray devices are arranged in the tank body and above a solid fermentation substrate of vinegar, and the liquid outlet pipe is arranged at the bottom of the tank body. By adopting the vinegar solid-state brewing integrative machine disclosed by the invention, vinegar solid-state brewing and vinegar spraying operations are integrated to realize multi-functionalization of the same equipment so as to shorten the fermentation period of the vinegar, ensure that the vinegar has a good flavor, improve the productivity of vinegar and facilitate equipment automation and high intelligent degree.

Owner:JIANGSU HENGSHUN VINEGAR IND +1

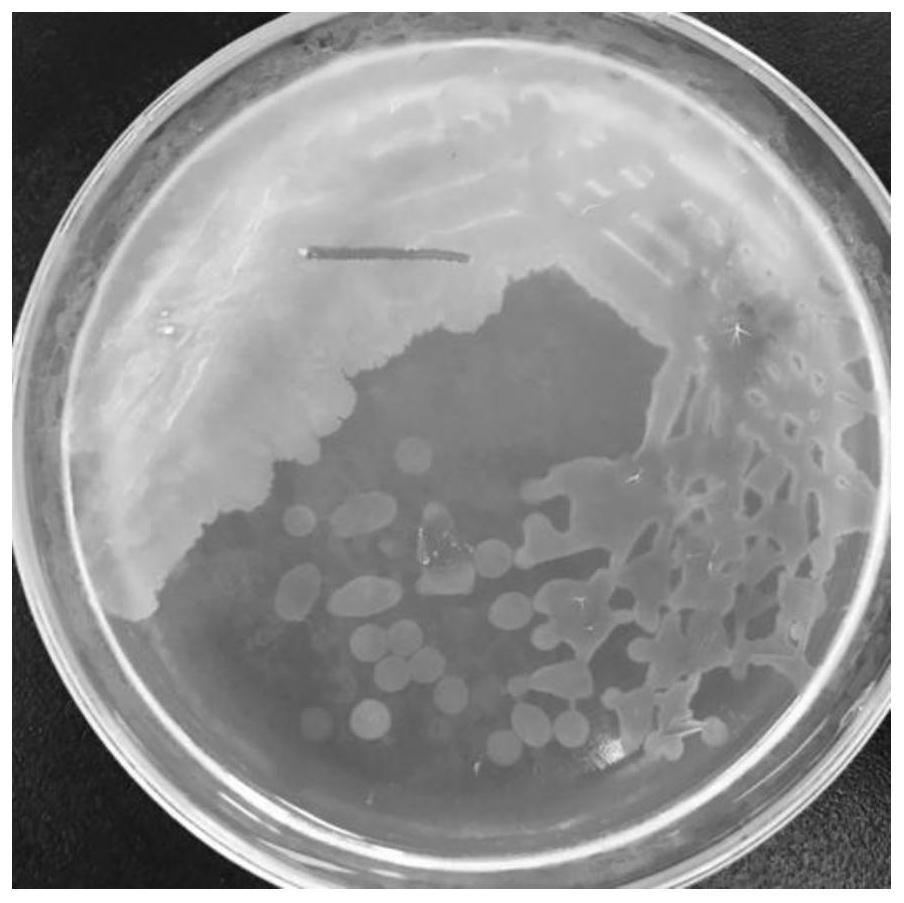

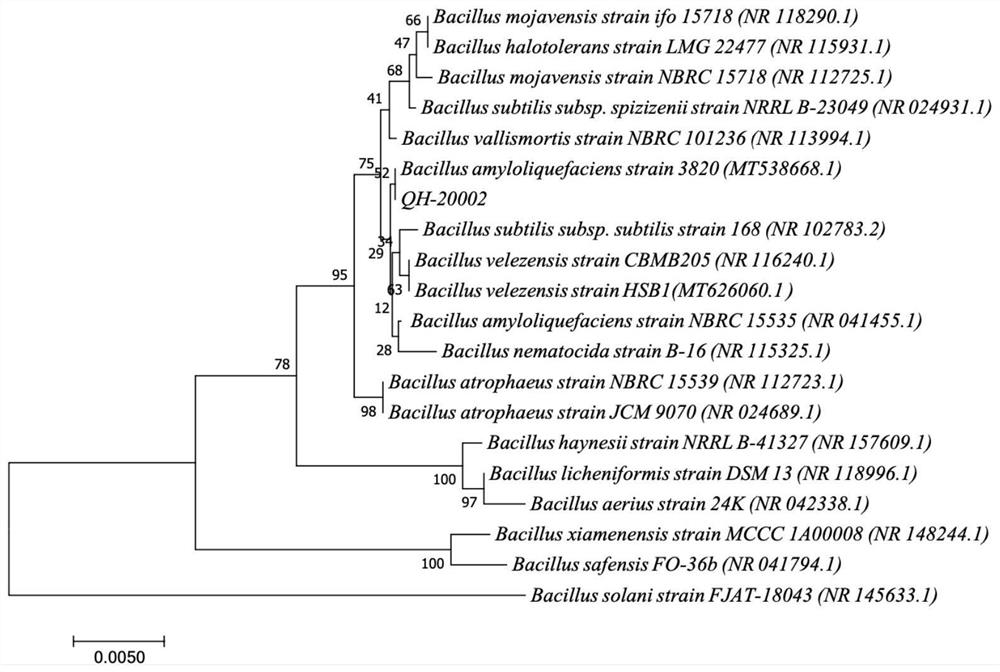

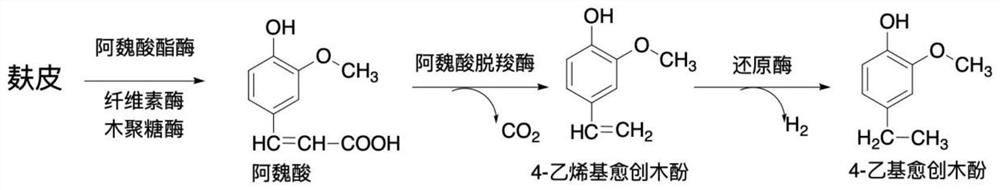

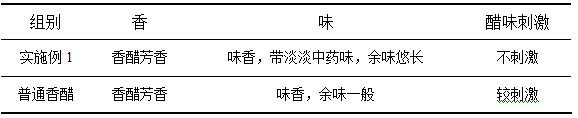

Bacillus amyloliquefaciens and application thereof in solid-state fermentation vinegar brewing

ActiveCN114480205AImprove flavor qualityImprove vinegar yieldBacteriaMicroorganism based processesProteasesCellulase

The invention discloses bacillus amyloliquefaciens and application of the bacillus amyloliquefaciens in solid-state fermentation table vinegar brewing. The preservation name of the bacillus amyloliquefaciens is QH-20002; the strain is preserved in the China General Microbiological Culture Collection Center (CGMCC), the preservation time is April 27, 2021, and the preservation number is CGMCC NO.22252. The bacillus amyloliquefaciens disclosed by the invention has the capability of producing acid-resistant amylase, protease and cellulase at high yield, also has the capability of producing feruloyl esterase and feruloyl decarboxylase, and can decompose a ferulate ester compound in a vinegar brewing raw material bran to generate flavor substances with baking fragrance, such as 4-vinyl guaiacol, 4-ethyl guaiacol, 4-methyl guaiacol, 4-methyl guaiacol, 4-methyl guaiacol, 4-methyl guaiacol, 4-methyl guaiacol, 4-methyl guaiacol and 4-methyl guaiacol. When the strain is applied to solid vinegar brewing as a brewing functional strain, the yield and the ammonia nitrogen content of vinegar can be increased, the vinegar production cost can be reduced, meanwhile, the flavor of the vinegar is improved to a certain extent, the product quality is remarkably improved, and good operability and economic benefits are achieved.

Owner:QIANHE CONDIMENT & FOOD CO LTD

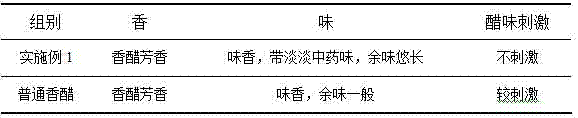

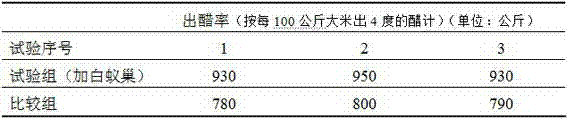

Termite vinegar and preparation method and applications thereof

InactiveCN102191161AHigh in nutrientsPromote fermentationVinegar preparationFood preparationBiotechnologyAcetic acid

The invention discloses termite vinegar and a preparation method and applications thereof. The preparation method of the termite vinegar provided by the invention comprises the following steps: alcoholic fermentation is performed to obtain swort, bran and rice bran powder are mixed evenly to obtain wine bran mixture, then the mature vinegar fermented grains prepared from vinegar fermented grains and termite nests are added; swort is added in the mature vinegar fermented grains per day, a layer of rice bran powder is covered on the mixture to ferment, the temperature is controlled to 30-35 DEGC for 5-7 days; the fermenting grains are turned over, the maximum temperature is controlled to less than 35-42 DEG C, fermentation is performed continuously and then completed when the temperature reaches the room temperature; post-fermentation is performed for 26-34 days; and the termite vinegar finished product is obtained after rinsing and decoction. The invention also discloses the applications of the termite vinegar in the preparation of nourishing drinks, food or flavorings. The formic acid in termite nests is utilized to promote fermentation, thus the vinegar yield and the high quality product rate can be increased; and the termite nests contain a lot of nutrients which can be combined with substances such as acetic acid to form a unique flavor.

Owner:谢华鸣 +1

Method for brewing vinegar by using raw materials and processed edible vinegar

The invention relates to a method for brewing vinegar by using raw materials and processed edible vinegar, and belongs to the technical field of brewing. The method for brewing vinegar by using the raw materials comprises the following steps: step one, treatment of a brewing pond; step two, pretreatment of the raw materials; step three, material throwing; step four, alcoholic fermentation; and step five, acetic fermentation. The raw materials are fermented in the brewing pond to brew the vinegar, rice is used as a raw material, rice cooking is omitted, the vinegar can be obtained within 20 days, the energy is saved effectively, the production period of brewing of the vinegar by the raw materials is shortened, and the production efficiency is improved; meanwhile, the vinegar yield can be improved further by the method, the production cost is reduced, and the produced vinegar is pure in color and taste, and is nutrient-rich; and more importantly, according to the process for brewing the vinegar by using the raw materials, purposes of saving grains, saving energy and reducing emission can be achieved really.

Owner:FUJIAN YONGCHUN JINCHUN BREWING

Five-cereal table vinegar brewing method and processing system

The invention belongs to the technical field of table vinegar brewing, and particularly relates to a five-cereal table vinegar brewing method and processing system. The brewing method comprises the following brewing steps: raw material crushing, cooking and liquefying, saccharifying, alcoholic fermentation, filtering, and acetic fermentation. The production process is simple, and the method is simple to operate and suitable for large-scale and small-scale production. Corn, wheat, millet, sorghum and pea are adopted as ingredients, and the taste and nutritional value are improved. The vinegar brewing process is improved, the decomposition of raw materials and the synergistic effect of microbial communities are facilitated, the biochemical performance is improved, more metabolites are generated, the flavor can be improved, and the vinegar yield can be increased. The production environment is clean and safe, and the fermentation is stable. A production system is simple, and a groove typefilter and a plate-and-frame filter press are combined and installed. The filtering efficiency is improved, and the vinegar flavor is improved.

Owner:宁夏兴宇绿色粗粮加工有限公司

The production process of traditional Ningxia returning home vinegar

ActiveCN104789440BOptimize the traditional production processPromote growth and reproductionVinegar preparationCooking & bakingYeast

The invention discloses a novel production process of traditional Ningxia Hui vinegar developed based on a traditional process and solves the problems that the current Ningxia Hui vinegar production process is too long in production period and complex in technology, unstable in product quality and low in raw material utilization rate. The traditional production process is modified, namely a thick-layer ventilation starter propagation technology is adopted in the starter propagation; the processes of liquefying at high temperature and saccharifying to manufacture the saccharification mash are adopted to manufacture the yeast; the traditional process of trilateral fermentation of the Ningxia Hui vinegar is kept in the solid state fermentation; a baking and fermenting process is added; a double-set heat spraying circulation method is adopted in the vinegar spraying process; a solar energy is used for aging; an excellent strain with high enzyme activity is used in starter propagation process; a high-activity yeast and various microbe compound starters are adopted for fermenting so as to enrich the microbe enzyme system; a modern biological fermentation technology is combined with the process to substitute the traditional control mode depending on experience; the Ningxia Hui vinegar technological process is systematized, the technological parameter is standardized and a best fermentation process condition is reached so that the product quality is guaranteed.

Owner:宁夏强尔萨生物科技有限公司

Method for ventilating reflux esterification of millet vinegar

InactiveCN103305397AReduce labor intensityUniform fermentationVinegar preparationRefluxFermentation condition

The invention discloses a method for ventilating reflux esterification of millet vinegar, belongs to the technical field of an acetic fermentation technology of table vinegar, and aims at solving the technical problem of providing the method for ventilating reflux esterification of the millet vinegar. The method is simple in equipment, convenient to operate, high in acid-producing rate, and easy to control fermentation conditions. The adopted technical scheme is as follows: the method comprises the steps of: refluxing and spraying vinegar juice at the bottom of a tank on a vinegar grain to control the temperature of the vinegar grain, ventilating and refluxing once at an interval of four hours, wherein the ventilating amount is 21-62.5 m<3>; the top temperature at the early stage is 38-40 DEG C; the time is 48-72 hours; the fermentation temperature at a later stage is 39-41 DEG C; the fermentation time is 22-27 days, so as to finish acetic fermentation. The method is widely applied to the technical field of fermentation of the millet vinegar.

Owner:SHANXI SANSHENGHE BREWING

Novel all-solid-state vinegar brewing process

The invention discloses a novel all-solid-state vinegar brewing process. The novel all-solid-state vinegar brewing process is characterized by comprising the following specific extraction steps: preparing strains; cooking raw materials; performing strain fermentation; performing acetic fermentation; sealing a tank; spraying vinegar; and obtaining finished products. The table vinegar prepared by the all-solid-state vinegar brewing process has the characteristics of being good in taste, sufficient in flavor, soft in acetic acid flavor, lasting in aftertaste, sour, sweet and delicious. Raw materials directly enter a fermentation tank after being cooked, early starch gelatinization, saccharification and alcoholic fermentation are completed at a time in the strain fermentation process, the efficiency is high, the equipment utilization rate is high, the operation is greatly simplified, and besides, the vinegar yield of products is increased. The process has the characteristics that the operation is simple, the yield is high, 10-12kg of vinegar with the acidity of 3.5 degrees is produced from per kilogram of main materials, the vinegar making process is simplified, the labor intensity isreduced, the vinegar making cost is greatly reduced, only 1kg of strains are required for producing one ton of vinegar, and the process is suitable for large-scale production of production enterprises.

Owner:镇江市恒威制曲机有限公司

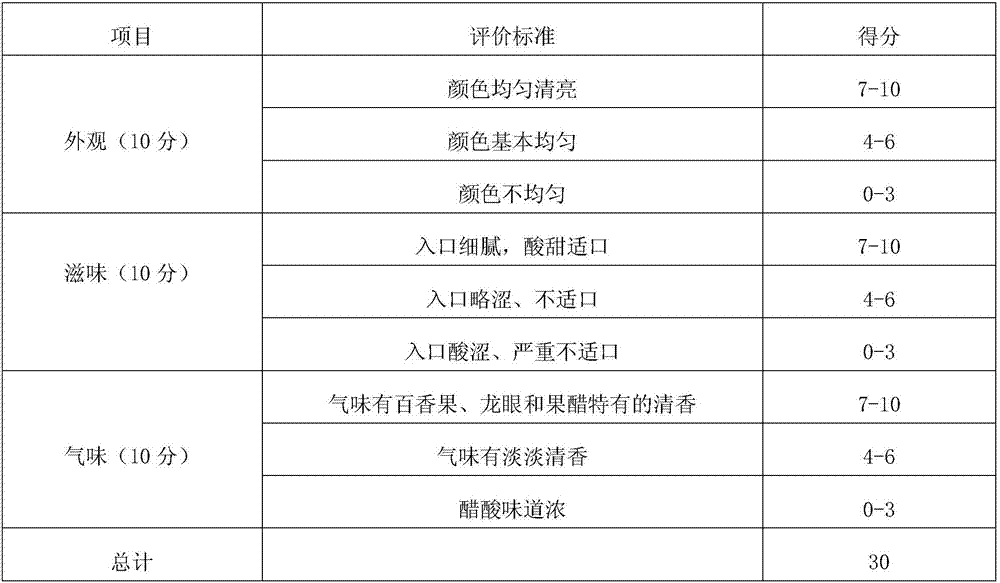

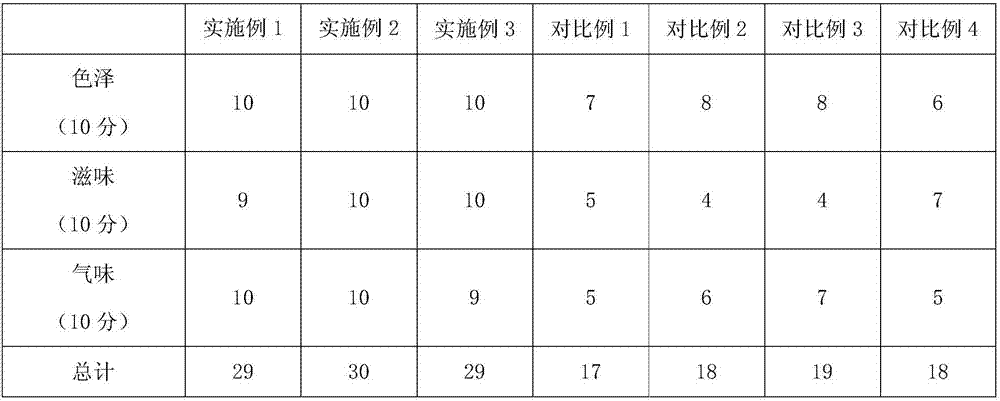

Passion-fruit-and-longan fruit vinegar and making method thereof

InactiveCN107245428AGreat tasteHigh in nutrientsDigestive systemVinegar preparationNutritive valuesAdditive ingredient

The invention provides a passion-fruit-and-longan fruit vinegar and a making method thereof, and belongs to the field of the food processing. The making method includes the steps that whole passion fruits and longan pulp serve as raw materials, fruit shells of the passion fruits are sectioned, then the product is treated with acid proteinase, and a solid-liquid mixture is obtained; then corn and sorghum are fermented with saccharomycetes and acetic acid bacteria, and basic vinegar is obtained; pulp of the passion fruits, the longan pulp and the solid-liquid mixture are fermented with the obtained basic vinegar, the obtained fermented product and ethyl-alcohol soaking-filtering liquid of fruit seeds are mixed, the mixture is put into a high-pressure homogenizer and treated, and the passion-fruit-and-longan fruit vinegar is obtained; nutritional ingredients of the passion-fruit-and-longan fruit vinegar can be completely kept, the passion-fruit-and-longan fruit vinegar obtained with the making method is convenient to eat and excellent in taste, has the rich nutritive value and the good health-care effect, and is suitable for eating of various populations.

Owner:广西驰胜农业科技有限公司

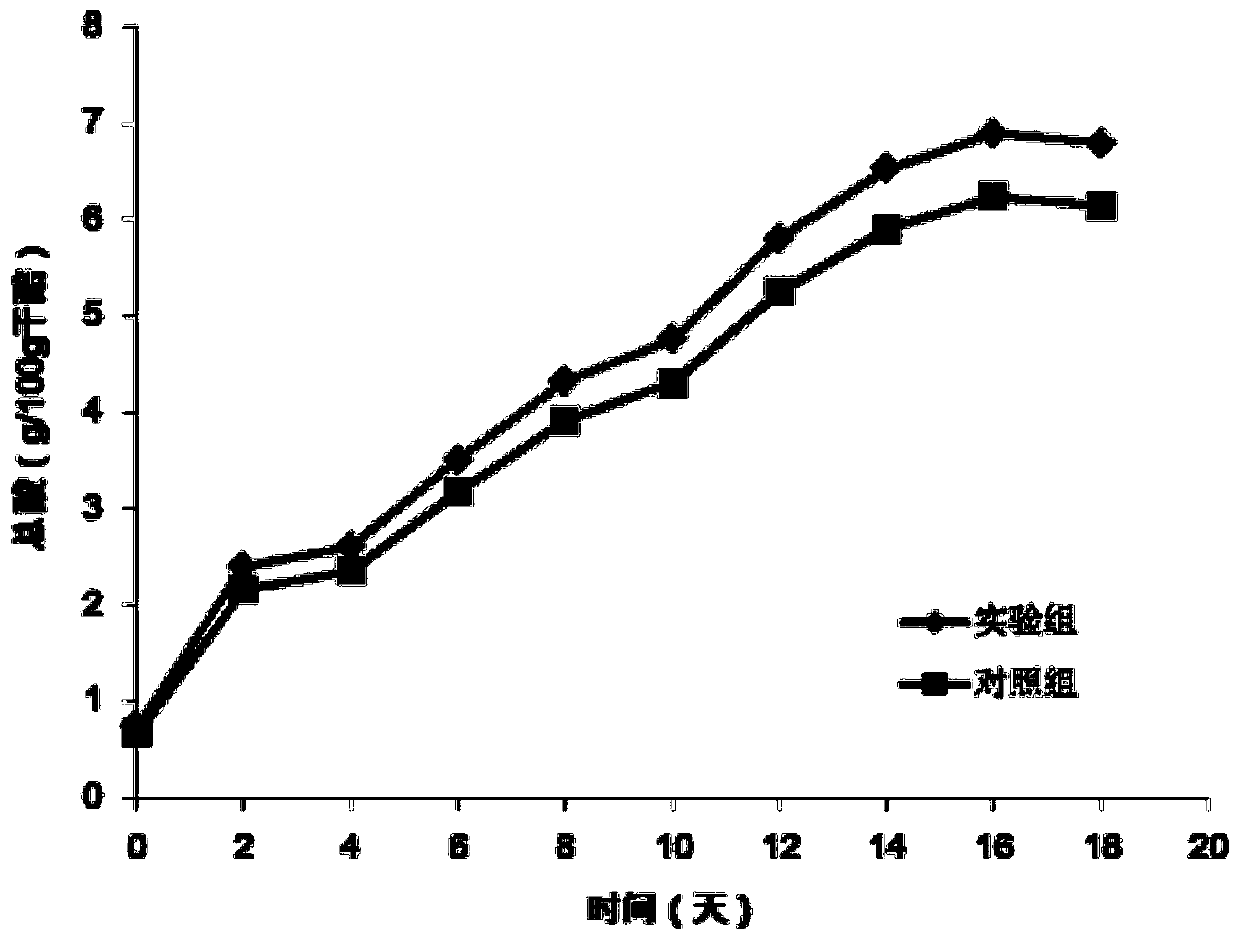

Vinegar koji of Chishui vinegar and preparation method thereof

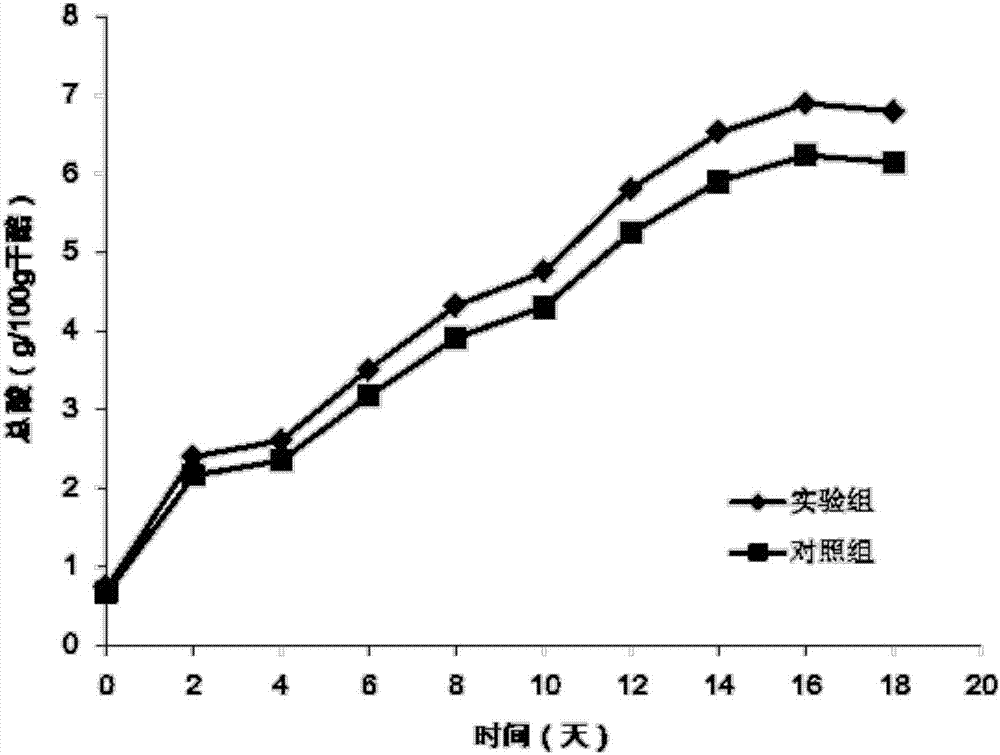

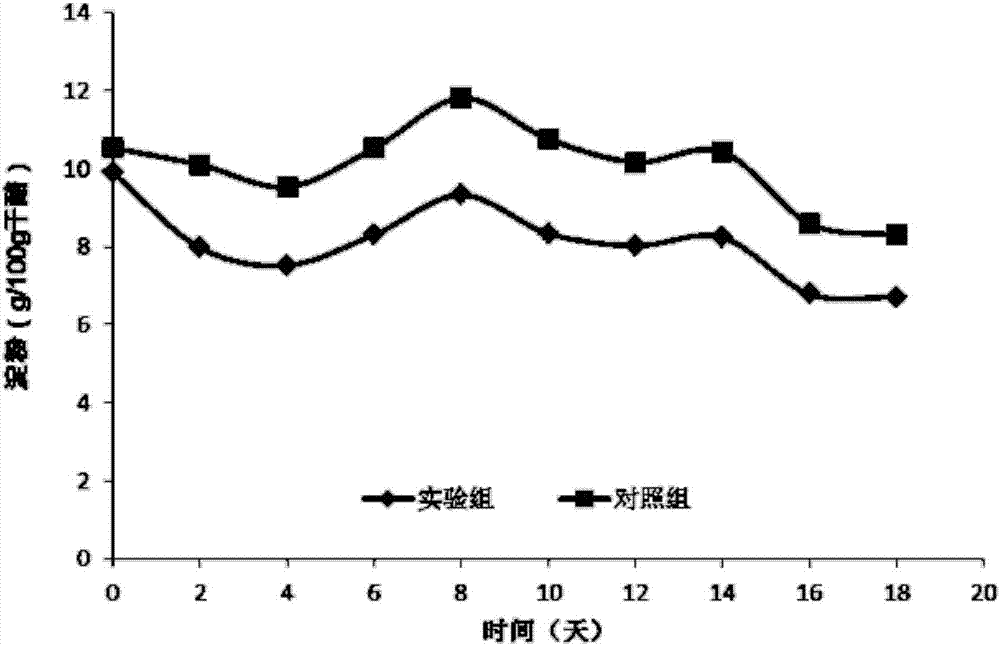

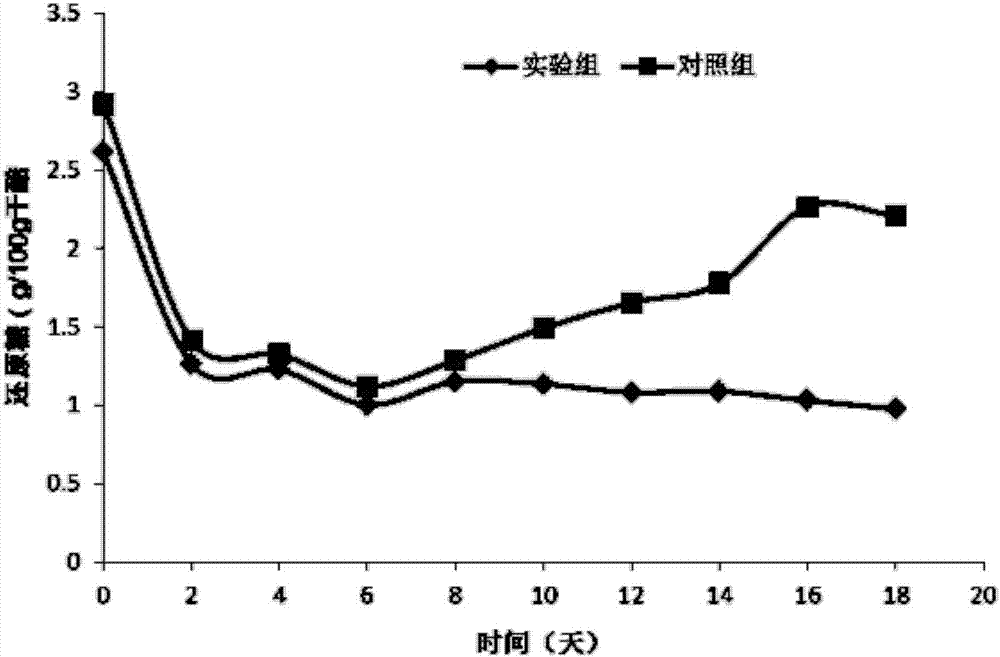

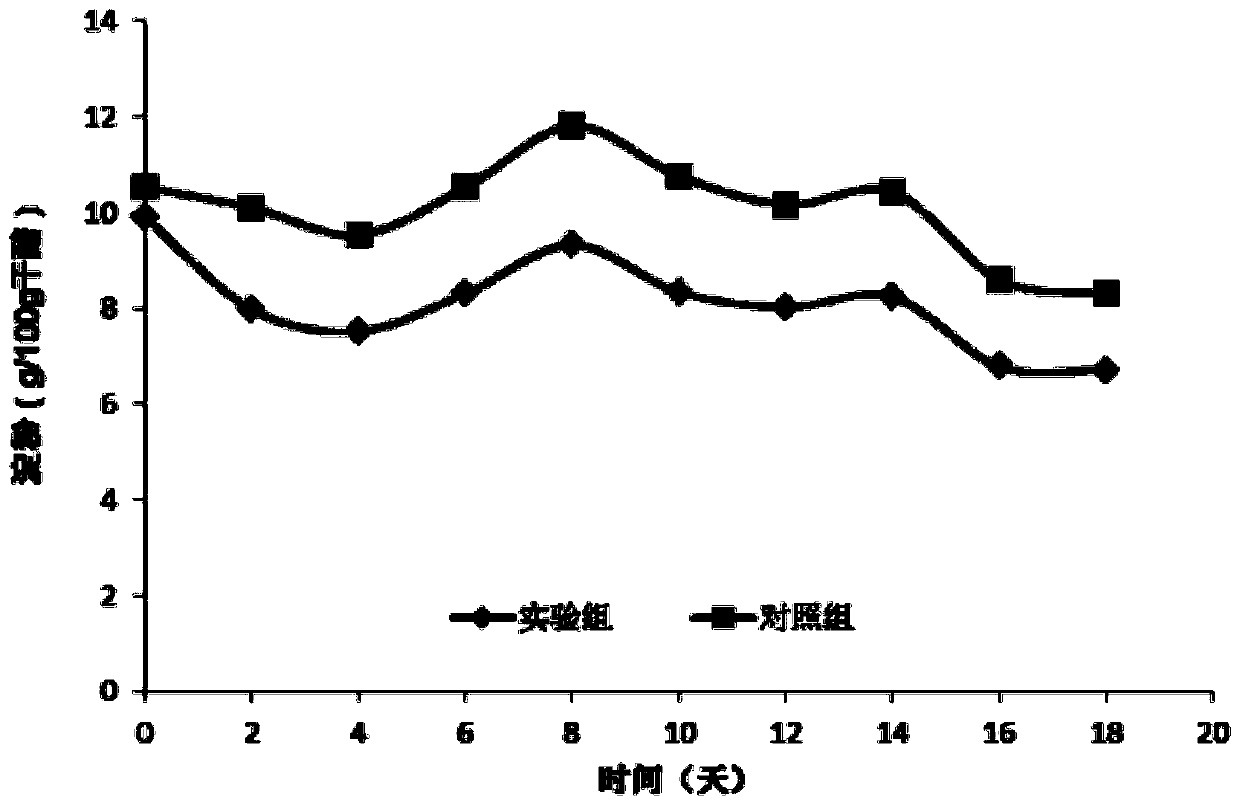

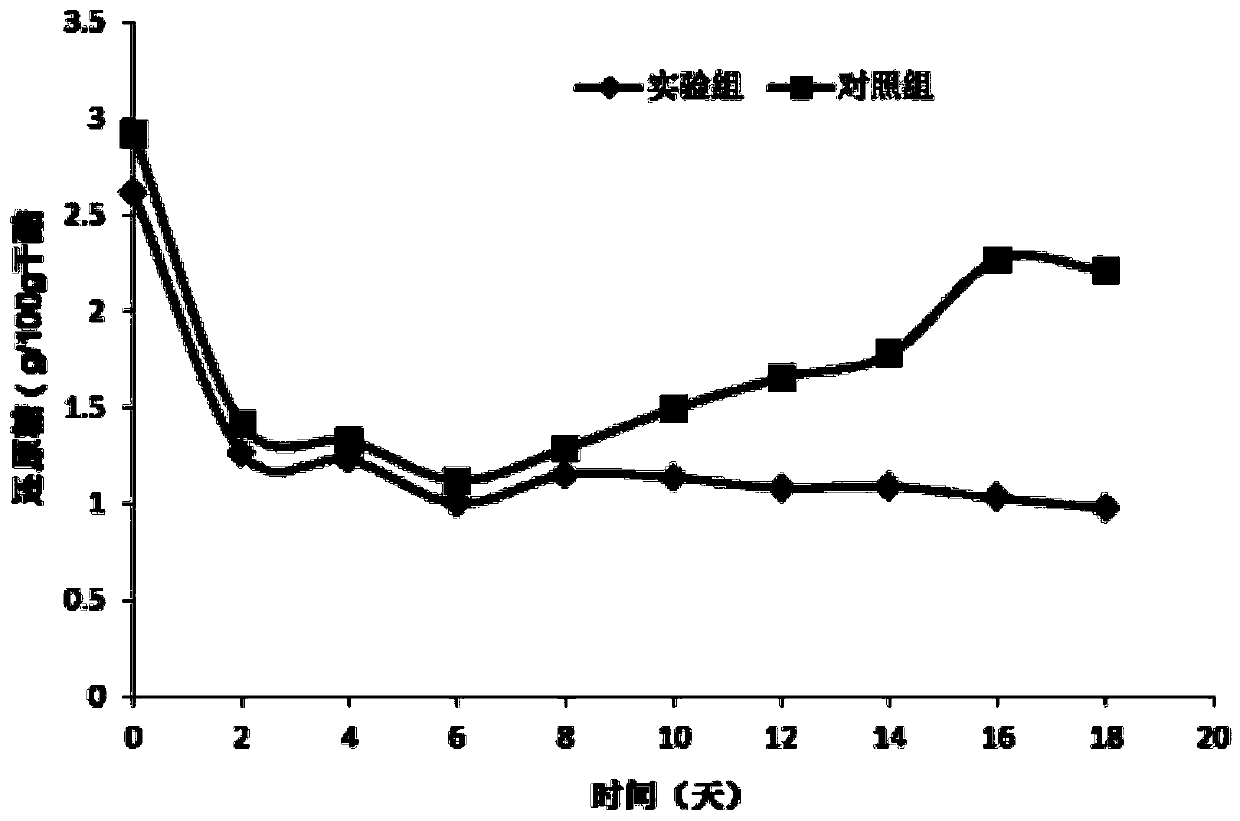

The invention discloses a vinegar koji of a Chishui vinegar and a preparation method thereof. The preparation method comprises the following steps: grass powder, Polygonum criopolitanum, kadsura pepper stem, L. fasciculiflora, Senecio scandens, negundo chastetree fruit, and dried tangerine peel are treated separately, the remaining Tiantai radix linderae, dahurian angelica root, Nardostachyos Rootand Rhizome, dark plum, ephedra stem, cassia twig, asarum heterotropoides, pachyrhizua angulatus, balloonflower root, peach kernel, Touerfeng, radix bupleuri, Lysimachia christinae, rust-coloured crotalaria herb with root, akebia stem, mosla dianthera, sinensis diels, walnut leaves, Chinese wingnut leaf, peach leaves, Qingqiugan, Diaoyugan, wheat bran and wheat are subjected to cleaning and drying treatment, the natural plants such as dark plum, peach kernel, grass powder, pachyrhizua angulatus, dahurian angelica root, balloonflower root, dried orange peel, and sinensis diels, as well as wheat bran and wheat are processed into mixed koji, and the above materials are naturally fermented according to a traditional technology, the product contains a variety of microorganisms such as Aspergillus, microzyme, and acetic acid bacteria, the obtained vinegar yield rate is high, a blank comparison test is performed, different formulas and different fermentation processes are used, a traditionalfermentation method is used for the blank, and the quality index of the vinegar koji and the total acid content of the vinegar fermented grains are obtained respectively.

Owner:贵州赤水古法酱香晒醋有限责任公司

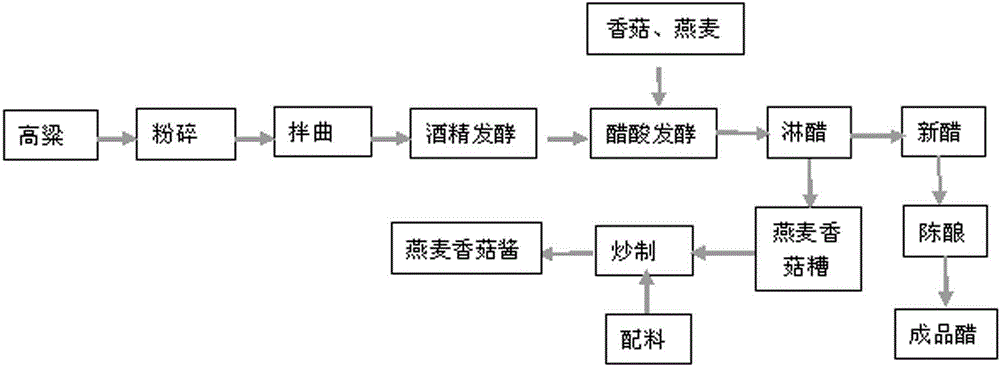

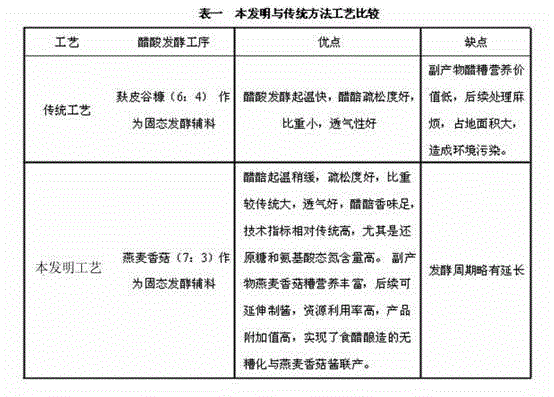

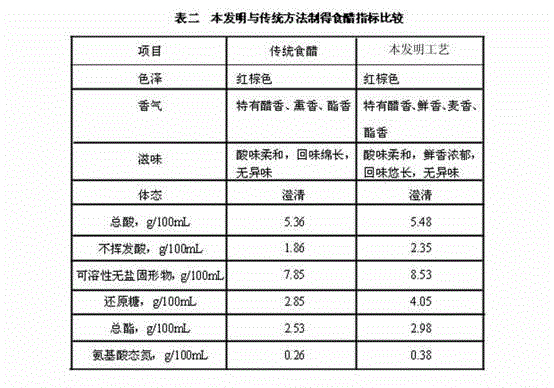

A technology of co-production of vinegar and mushroom sauce using oats and mushrooms as fermentation auxiliary materials

ActiveCN103555551BImprove vinegar yieldReduce manufacturing costVinegar preparationFood preparationFiberAdditive ingredient

The invention relates to the field of food processing, and particularly relates to a technology for brewing vinegar and producing mushroom sauce by adopting oat and mushrooms as auxiliary fermentation materials. The technical problems that vinegar residue generated in a traditional vinegar brewing technology causes serious pollution and is high in recycling energy consumption, low in additional value of by-products and the like are solved. The technology for brewing vinegar and producing mushroom sauce comprises the following steps: selecting raw materials; processing the selected raw materials; wetting the processed raw materials; cooking; stirring with yeast; fermenting by alcohol; carrying out acetic acid fermentation with the oat and the mushrooms as the auxiliary fermentation materials; sealing in unfiltered wine for after-ripening; and pouring vinegar and ageing. The table vinegar brewing technology with solid fermentation disclosed by the invention adopts the oat and the mushrooms as the auxiliary fermentation materials, and can be applied to production of various grain vinegar; solid oat and mushroom residue generated after vinegar pouring is over 30% in protein content, is abundant in nutrition, does not contain a crude fiber component, and can be conveniently prepared into a delicious food. The table vinegar produced by the technology disclosed by the invention is high in yield, low in production cost and good in product quality, is pure and excellent and has environment protecting and energy-saving effects.

Owner:山西金龙鱼梁汾醋业有限公司

A kind of preparation method of okra vinegar

The invention relates to a preparation method of okra vinegar, which mainly comprises the following steps: okra raw material selection, pulping, enzymolysis, blending, sterilization, alcohol fermentation, acetic fermentation, afterripening, vinegar pouring, sterilization and the like. The okra vinegar prepared by the method has the advantages of bright color and sour mouthfeel, has the particular aroma of okra, and has certain health-care functions. The method can effectively solve a series of problems caused by large area okra planting, centralized ripening and short storage and preservation time, greatly promotes the processing and utilization of the fresh okra fruit, and is beneficial to smooth proceeding of the okra industry. The vinegar produced by the method is blended in the later period to lower the acidity, and blended with sweet substances to prepare the beverage, thereby developing a beverage with health-care functions, further satisfying the demands for special people and having broad market prospects.

Owner:HENAN UNIV OF SCI & TECH

Termite vinegar and preparation method and applications thereof

InactiveCN102191161BHigh in nutrientsPromote fermentationVinegar preparationFood preparationBiotechnologyAcetic acid

The invention discloses termite vinegar and a preparation method and applications thereof. The preparation method of the termite vinegar provided by the invention comprises the following steps: alcoholic fermentation is performed to obtain swort, bran and rice bran powder are mixed evenly to obtain wine bran mixture, then the mature vinegar fermented grains prepared from vinegar fermented grains and termite nests are added; swort is added in the mature vinegar fermented grains per day, a layer of rice bran powder is covered on the mixture to ferment, the temperature is controlled to 30-35 DEGC for 5-7 days; the fermenting grains are turned over, the maximum temperature is controlled to less than 35-42 DEG C, fermentation is performed continuously and then completed when the temperature reaches the room temperature; post-fermentation is performed for 26-34 days; and the termite vinegar finished product is obtained after rinsing and decoction. The invention also discloses the applications of the termite vinegar in the preparation of nourishing drinks, food or flavorings. The formic acid in termite nests is utilized to promote fermentation, thus the vinegar yield and the high quality product rate can be increased; and the termite nests contain a lot of nutrients which can be combined with substances such as acetic acid to form a unique flavor.

Owner:谢华鸣 +1

Method and equipment for producing edible vinegar

A process for preparing the edible vinegar with high output rate features that its raw materials include proportionally sorghum grains, wheat bran, yeast, beta-amylase, dried yeast, rice husk, vinegar dregs, edible salt, and sodium benzoate. A novel fire fumigating apparatus for high uniformity of fire fumigating to all jars is also disclosed.

Owner:明克宽

The method of a marine source Bacillus licheniformis for vinegar bioaugmentation

ActiveCN107418909BAdd flavorImprove qualityBacteriaMicroorganism based processesBiotechnologyBacillus licheniformis

The invention discloses a method for using a strain of bacillus licheniformis derived from marine sources for vinegar bioaugmentation, and belongs to the technical field of food brewing. The present invention screens a strain of Bacillus licheniformis (B. licheniformis) CCTCC NO:M 2017209 from the marine environment, which can grow at 65°C and has high amylase-producing ability. The bacterial strain is made into bacterial powder to strengthen the acetic acid fermentation of vinegar. This method has the advantages of increasing the utilization rate of raw materials, improving the product flavor of vinegar and improving the quality of vinegar.

Owner:JIANGNAN UNIV

Method for preparing gamma-aminobutyric acid enriched vinegar

ActiveCN101603000BMild tasteInhibit bacteriaMicroorganism based processesVinegar preparationSerum igeGamma-Aminobutyric acid

The invention discloses a method for preparing gamma-aminobutyric acid rich vinegar, belongs to the technical field of seasoning brewing engineering, and particularly relates to the technical field of edible vinegar production. The method for preparing health-care vinegar comprises processes of liquefaction, saccharification, yeast addition, yeast fermentation and acetic fermentation; and lactobacillus brevis and acetic acid bacteria are added in the acetic fermentation process, the lactobacillus brevis is added before the acetic acid bacteria is added or synchronously added with the acetic acid bacteria, and sodium glutamate is added when the lactobacillus brevis is added. The product of the invention is soft when entering the mouth and acid after tasting, has no peculiar smell, has clear vinegar liquid and gloss, and is amber edible vinegar, or the edible vinegar with health-care functions of reducing blood pressure, promoting sleep, reducing serum cholesterol, delaying senility, and the like.

Owner:TIANDI YIHAO BEVERAGE JIANGMEN CITY

A method for preparing wine mash based on multi-enzyme system and its application in vinegar brewing

ActiveCN107034087BAlcohol conversion rate is highImprove conversion rateMicroorganism based processesAlcoholic beverage preparationBiotechnologyAmylase

The invention discloses a method for preparing wine mash based on a multi-enzyme system and its application in vinegar brewing. It uses α-amylase, pullulanase, glucoamylase, cellulase, protease, A variety of biological enzyme preparations such as lipase are combined with traditional koji, enzymatically hydrolyzed by adding step by step, and then fermented by alcohol to obtain wine mash. On the basis of liquid saccharification, the method can further improve the utilization rate of raw and auxiliary materials, improve the conversion rate of alcohol content, reduce production costs, and at the same time retain the product flavor of traditional technology.

Owner:JIANGSU HENGSHUN VINEGAR IND

A liquid submerged fermentation process of wolfberry licorice apple health-care vinegar

ActiveCN106367284BQuality improvementShort fermentation cycleDigestive systemVinegar preparationBiotechnologyNutritive values

The invention provides a liquid submerged fermentation technique of Chinese wolfberry / licorice root / apple health-care vinegar. The technique comprises the following steps: (1) preparation of apple raw juice; (2) sugar blending; (3) yeast primary fermentation; (4) liquid submerged acetic fermentation; (5) rough filtration, afterripening; (6) preparation of Chinese wolfberry / licorice root leaching solution; and (7) blending, sterilization and filling. The technique organically combines the health-care fruit vinegar with the particular Chinese wolfberry and licorice root in Ningxia Province and utilizes the liquid submerged fermentation process, thereby greatly shortening the fermentation period. The prepared Chinese wolfberry / licorice root / apple health-care vinegar has the advantages of high nutritive value, fresh and unique taste, clear appearance, favorable color and small pungency of acetic acid.

Owner:宁夏强尔萨生物科技有限公司

A vinegar solid-state brewing all-in-one machine

ActiveCN106244413BAchieve multi-functionalityIncrease profitVinegar preparationProcess engineeringMechanical engineering

The invention discloses a vinegar solid-state brewing integrative machine. The vinegar solid-state brewing integrative machine comprises a tank body which is of a horizontal rotary cylinder, spiral material turning strips, a through-long filter plate, spray devices, a ventilation pipe and a liquid outlet pipe, wherein a feed inlet is formed in one end of the tank body, and a discharge port is formed in the other end of the tank body, the spiral material turning strips are arranged on the inner wall of the tank body and between the feed inlet and the discharge port, and the ventilation pipe is connected to the tank body; for the fermentation site of the tank body, the through-long filter plate is arranged above the inner bottom of the tank body, and a cavity is formed between the through-long filter plate and the bottom of the tank body, the spray devices are arranged in the tank body and above a solid fermentation substrate of vinegar, and the liquid outlet pipe is arranged at the bottom of the tank body. By adopting the vinegar solid-state brewing integrative machine disclosed by the invention, vinegar solid-state brewing and vinegar spraying operations are integrated to realize multi-functionalization of the same equipment so as to shorten the fermentation period of the vinegar, ensure that the vinegar has a good flavor, improve the productivity of vinegar and facilitate equipment automation and high intelligent degree.

Owner:JIANGSU HENGSHUN VINEGAR IND +1

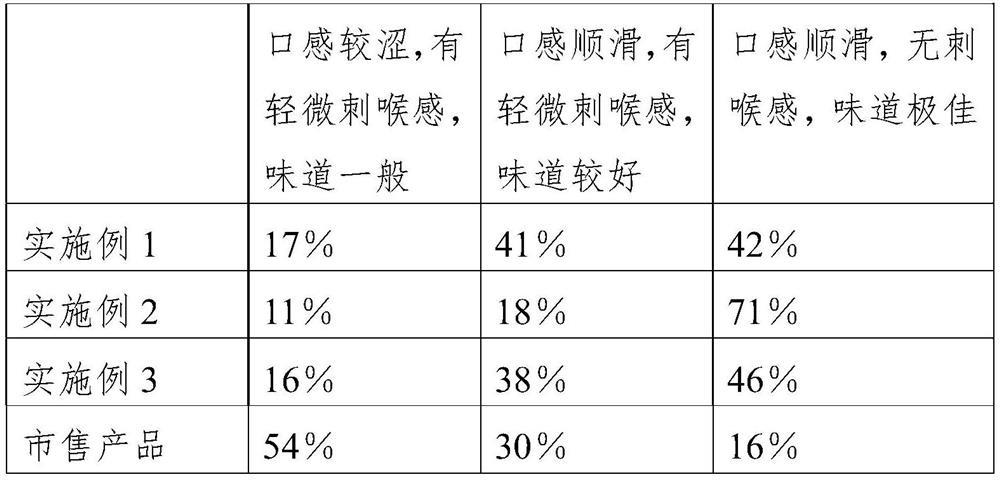

Stomach-invigorating digestion-promoting persimmon vinegar and processing technology thereof

PendingCN112481069AImprove vinegar yieldUnique tasteDigestive systemVinegar preparationFruit FlavorMouthfeel

The invention discloses stomach-invigorating digestion-promoting persimmon vinegar and a processing technology thereof. The persimmon vinegar comprises the following preparation raw materials in partsby mass: 80-90 parts of persimmons, 0.2-0.3 part of dry yeast powder, 4-6 parts of honey, 8-10 parts of bran and 5-7 parts of malt, wherein the used auxiliary materials comprise the following components in parts by mass: 2-4 parts of Chinese yams, 4-8 parts of poria cocos, 7-9 parts of haws, 35 parts of chrysanthemums, 5-7 parts of lotus seeds, 5-7 parts of hippophae rhamnoides fruits, 0.5-0.7 part of edible salt and 3-5 parts of sugar. Persimmon is used as a main material, and bran, malt and persimmon are uniformly mixed and fermented together, so that the vinegar yield is greatly improved,the fruit flavor of persimmon and the aroma of malt and bran are mixed, and the persimmon vinegar is rich in aroma, smoother in taste, free of throat pricking feeling and more suitable for people's taste preference.

Owner:刘瑞

A kind of solid-state vinegar brewing method that improves the utilization rate of starch

ActiveCN109161468BIncrease profitReduce starch contentVinegar preparationBiotechnologyLactic acid bacterium

The invention discloses a solid vinegar brewing method for increasing the utilization rate of starch and belongs to the technical field of food seasonings. According to the method, an acetic fermentation stage and a fermented grain sealing stage of edible vinegar are controlled, amylase is added at a later acetic fermentation stage, and lactic acid bacteria and aroma production yeast are inoculated at the fermented grain sealing stage. The later acetic fermentation stage has the judgment standard that a vinegar fermentation product temperature is less than 40 DEG C, and the amylase is acid amylase. At the later acetic fermentation stage, the acid amylase is added, starch left in raw materials is further decomposed into a small molecular sugar, and a great deal of lactic acid is generated by the lactic acid bacteria inoculated at the fermented grain sealing stage by virtue of the small molecular sugar, so that the starch utilization rate can be increased, the vinegar yield can be increased, wastes can be reduced, and the solid edible vinegar can be produced economically and environmental-friendly.

Owner:JIANGNAN UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com