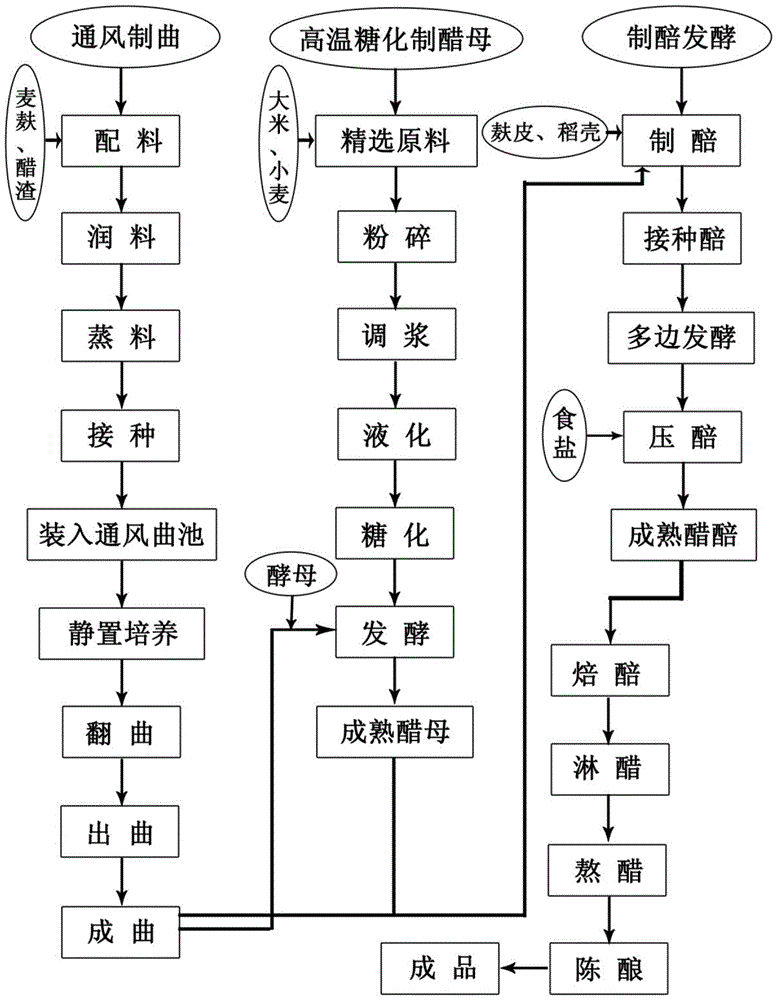

The production process of traditional Ningxia returning home vinegar

A kind of technology for returning old vinegar and production process, which is applied in the field of vinegar brewing, which can solve the problems of low utilization rate of raw materials, unstable product quality, long production cycle, etc., and achieves the advantages of forming aromatic substances, facilitating mechanized production, The effect of short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A manufacturing process of traditional Ningxia returning home vinegar, comprising the following steps:

[0055] A. Ventilated koji making

[0056] a. Ingredients: the raw materials are equipped with bran accounting for 85% to 90% of the total weight of raw materials, and vinegar residues accounting for 10% to 15% of the total weight of raw materials are added to increase the degree of looseness and air permeability;

[0057] b. Moisturizing: add water to the above raw materials for moistening, the amount of water added is 85% to 95% of the total weight of raw materials, and the time for moistening is 1 to 2 hours;

[0058] c. Steaming material: Spread the moistened koji material evenly and put it into the steamer for steaming. The steaming time is 40 minutes, and the moisture content of the steaming material is controlled between 45% and 48%;

[0059] d. Inoculation: After the steaming is completed, the steamed material is cooled (cooled) to 38-40°C through the steamer...

Embodiment 2

[0092] A manufacturing process of traditional Ningxia returning home vinegar, comprising the following steps:

[0093] A. Ventilated koji making

[0094] a. Ingredients: the raw materials are equipped with bran accounting for 85% to 90% of the total weight of raw materials, and vinegar residues accounting for 10% to 15% of the total weight of raw materials are added to increase the degree of looseness and air permeability;

[0095] b. Moisturizing: add water to the above raw materials for moistening, the amount of water added is 85% to 95% of the total weight of raw materials, and the time for moistening is 2 to 3 hours;

[0096] c. Steaming material: Spread the moistened koji material evenly and put it into the steamer for steaming. The steaming time is 40 minutes, and the moisture content of the steaming material is controlled between 45% and 48%;

[0097]d. Inoculation: After the steaming is completed, the steamed material is cooled (cooled) to 38-40°C through the steamer ...

Embodiment 3

[0130] A manufacturing process of traditional Ningxia returning home vinegar, comprising the following steps:

[0131] A. Ventilated koji making

[0132] a. Ingredients: the raw materials are equipped with bran accounting for 85% to 90% of the total weight of raw materials, and vinegar residues accounting for 10% to 15% of the total weight of raw materials are added to increase the degree of looseness and air permeability;

[0133] b. Moisturizing: add water to the above raw materials for moistening, the amount of water added is 85% to 95% of the total weight of raw materials, and the time for moistening is 3 to 4 hours;

[0134] c. Steaming material: Spread the moistened koji material evenly and put it into the steamer for steaming. The steaming time is 40 minutes, and the moisture content of the steaming material is controlled between 45% and 48%;

[0135] d. Inoculation: After the steaming is completed, the steamed material is discharged through the retort machine and cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com