Sea-buckthorn fruit vinegar and preparation method thereof

The technology of sea buckthorn fruit and sea buckthorn is applied in the field of sea buckthorn fruit vinegar and its preparation, and can solve the problems of insufficient color, fragrance, taste, health care function, restrict the market expansion of sea buckthorn fruit vinegar, and be difficult to produce on a large scale, and shorten the fermentation time. , The effect of stable product quality and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Strain expansion

[0034] 1. Yeast expansion

[0035] Inclined culture: 10°Bx wort, 2% agar, connected with Angel Wine Yeast Special Yeast SY (Hubei Angel Yeast Co., Ltd.), culture at 28~30°C for 24h.

[0036] The culture method of the triangular flask is that 150mL of 10°Bx wort is placed in a 250mL triangular flask, connected to the special yeast SY for Angel wine, shake well, and cultivated at 28-30°C for 24h.

[0037] Primary expansion culture: Take a 10mL test tube and fill it with 5mL of clarified sea-buckthorn juice at 07kg / cm 2 Sterilize under pressure for 20 minutes. After cooling, take 2 to 3 rings of yeast into a test tube, and place it in a constant temperature incubator at 28-30°C for 24 hours.

[0038] Secondary expansion culture: Take a 250mL Erlenmeyer flask, fill it with 100mL of sterilized clarified sea buckthorn juice, insert the above-mentioned yeast at 3% of the access volume, and place it in a constant temperature incubator at 28-30°C for 24h.

[0...

Embodiment 2

[0044] Embodiment 2: A preparation method of sea buckthorn fruit vinegar, which includes the following steps:

[0045] S1. Sorting: Select fully mature sea buckthorn to remove pests, mildew, rotten fruits, leaves, branches and other impurities;

[0046] S2. Washing: Rinse the sorted sea buckthorn with running water;

[0047] S3. Beating: Beat the washed seabuckthorn, and remove the peel and core to obtain seabuckthorn pulp;

[0048] S4. Concentration: Vacuum concentration of sea buckthorn pulp, and concentrate to a solid content of 62%;

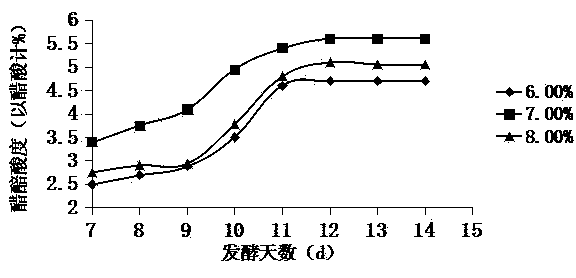

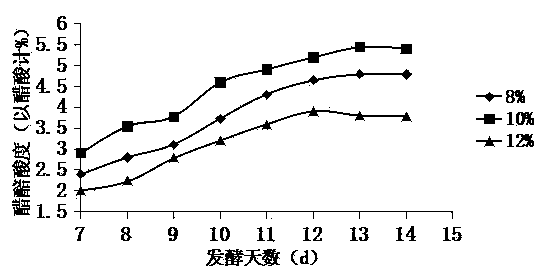

[0049] S5. Adjust the sugar content and acidity: add white sugar and calcium carbonate to the concentrated fruit puree to adjust the total sugar content of the concentrated fruit puree to 8% and the pH value to 3.5;

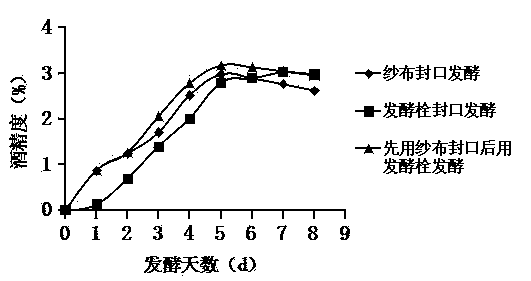

[0050] S6. Alcohol fermentation: Put the seabuckthorn slurry obtained in step S5 in a fermentation tank, add a secondary expansion yeast fermentation broth of 8% by mass of seabuckthorn slurry, stir evenly, and perform alcohol fermentation...

Embodiment 3

[0053] Embodiment 3: A preparation method of sea buckthorn fruit vinegar, which includes the following steps:

[0054] S1. Sorting: Select fully mature sea buckthorn to remove pests, mildew, rotten fruits, leaves, branches and other impurities;

[0055] S2. Washing: Rinse the sorted sea buckthorn with running water;

[0056] S3. Beating: Beat the washed seabuckthorn, and remove the peel and core to obtain seabuckthorn pulp;

[0057] S4. Concentration: Vacuum concentration of sea buckthorn pulp, and concentrate to a solid content of 68%;

[0058] S5. Adjust the sugar content and acidity: add fructose and calcium carbonate to the concentrated fruit puree to adjust the total sugar content of the concentrated fruit puree to 16% and the pH value to 4.5;

[0059] S6. Alcohol fermentation: Put the seabuckthorn slurry obtained in step S5 in a fermentation tank, add a secondary expansion yeast fermentation broth of 15% by weight of the seabuckthorn slurry, stir evenly, and perform alcohol ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com