Termite vinegar and preparation method and applications thereof

A technology for termites and vinegar fermented grains, which is applied in the preparation, application, food preparation and other directions of vinegar, can solve the problem of no effective and safe method to improve the vinegar yield, and achieves the improvement of the vinegar yield, the high-quality product rate, and the nutritional content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

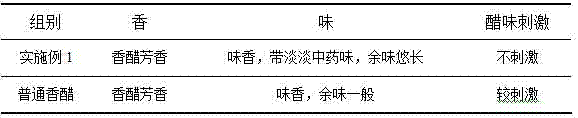

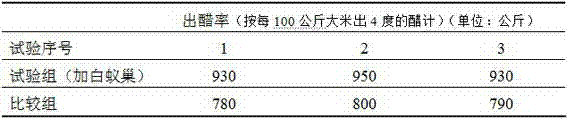

Examples

Embodiment 1

[0018] Alcoholic fermentation: rice is taken as raw material to obtain wine mash through maceration, cooking, saccharification with koji, and fermentation.

[0019] Preparation of fermented grains: add 60 kg of bran and 60 kg of bran to every 180 kg of wine mash and mix well to obtain a mixture of wine bran, then add vinegar fermented grains and termite nests to make mature vinegar grains, wherein every 350 kg of wine bran mixture is added 5 1 kg of vinegar grains and 15 kg of termite nests.

[0020] Pre-fermentation: Mix wine mash with an alcohol content of 6-9 degrees into the mature vinegar fermented grains every day, and cover it with a layer of bran for fermentation. The temperature is controlled at 30-35°C and the fermentation is continued for 5 days;

[0021] Middle fermentation: Turn over the vinegar grains obtained in the above steps. On the first day, turn the vinegar grains from top to bottom into another fermentation container, and then turn them back to the origin...

Embodiment 2

[0026] Alcoholic fermentation: take the mixture of rice and sorghum as the raw material to obtain wine mash through maceration, cooking, saccharification with koji, and fermentation.

[0027] Preparation of fermented grains: add 60 kg of bran and 60 kg of bran to every 180 kg of wine mash and mix well to obtain a mixture of wine bran, then add vinegar fermented grains and termite nests to make mature vinegar grains, wherein every 350 kg of wine bran mixture is added 5 1 kg of vinegar grains and 5 kg of termite nests.

[0028] Pre-fermentation: Mix wine mash with an alcohol content of 9 degrees into the mature vinegar grains every day, and cover it with a layer of bran for fermentation. The temperature is controlled at 30-35°C and the fermentation is continued for 7 days;

[0029] Middle fermentation: Turn over the vinegar grains obtained in the above steps. On the first day, turn the vinegar grains from top to bottom into another fermentation container, and then turn them back...

Embodiment 3

[0034] Alcoholic fermentation: rice is taken as raw material to obtain wine mash through maceration, cooking, saccharification with koji, and fermentation.

[0035] Preparation of fermented grains: add 60 kg of bran and 60 kg of bran to every 180 kg of wine mash and mix well to obtain a mixture of wine bran, then add vinegar fermented grains and termite nests to make mature vinegar grains, wherein every 350 kg of wine bran mixture is added 5 1 kg of vinegar grains and 30 kg of termite nests.

[0036] Pre-fermentation: Mix the wine mash with an alcohol content of 6 degrees into the mature vinegar grains every day, and cover it with a layer of bran for fermentation. The temperature is controlled at 30-35°C and the fermentation is continued for 5 days;

[0037] Middle fermentation: Turn over the vinegar grains obtained in the above steps. On the first day, turn the vinegar grains from top to bottom into another fermentation container, and then turn them back to the original ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com