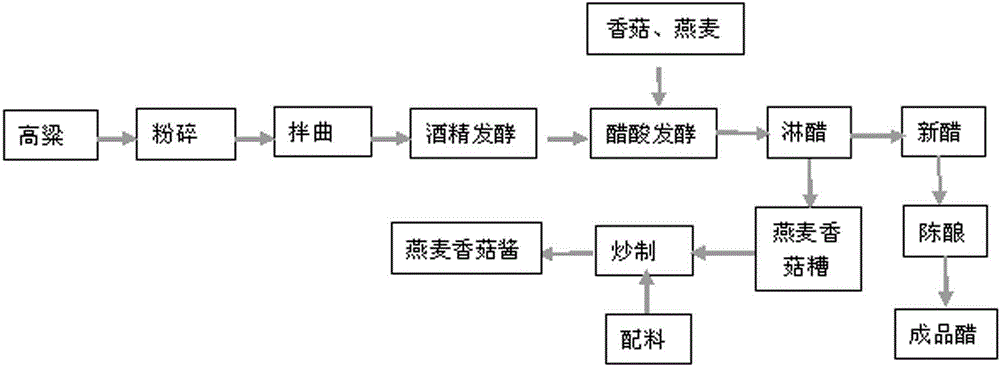

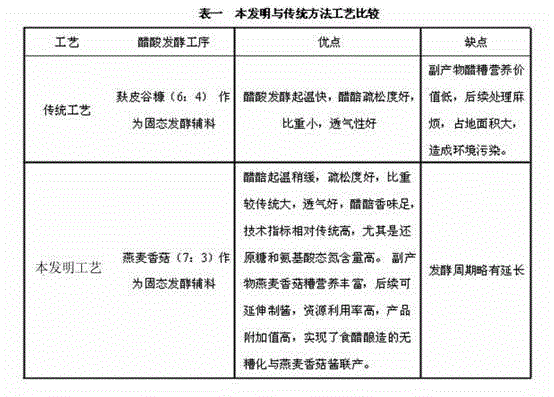

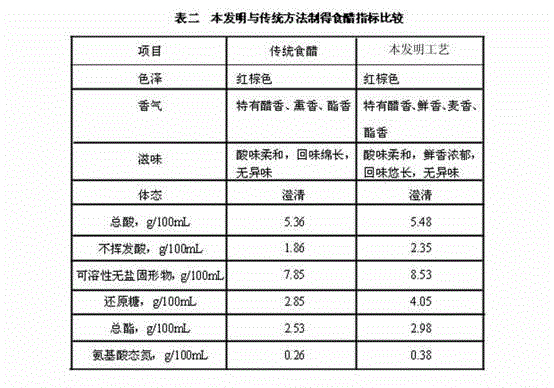

A technology of co-production of vinegar and mushroom sauce using oats and mushrooms as fermentation auxiliary materials

A technology for shiitake sauce and shiitake mushrooms, which is applied in the field of food processing, can solve the problems of vinegar lees pollution, high energy consumption of vinegar lees recycling, low added value of by-products, etc., and achieves high vinegar yield, low production cost and good product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A process for making vinegar and co-producing shiitake mushroom sauce using oats and shiitake mushrooms as fermentation auxiliary materials, including the vinegar brewing process using oats and shiitake mushrooms as fermentation auxiliary materials; the vinegar brewing process using oats and shiitake mushrooms as fermentation auxiliary materials comprises the following steps: (1 ) raw material selection

[0037] Choose fresh and mildew-free sorghum as raw material;

[0038] (2) Raw material processing

[0039] The above-mentioned raw materials are pulverized, and the pulverization degree is 50 mesh;

[0040] (3) Moisturizer

[0041] Add 65% water of the weight of the above raw materials, and keep stirring, so that the raw materials absorb water evenly and sufficiently;

[0042] (4) Cooking

[0043] Put the moistened material into the steamer, and steam for 63 minutes at 121°C and 0.10 Mpa;

[0044] (5) mix song

[0045] Mix Daqu and water in the same mass ratio, p...

Embodiment 2

[0058] A process for making vinegar and co-producing shiitake mushroom sauce using oats and shiitake mushrooms as fermentation auxiliary materials is characterized in that it includes a vinegar brewing process using oats and shiitake mushrooms as fermentation auxiliary materials; the vinegar brewing process using oats and shiitake mushrooms as fermentation auxiliary materials includes the following Steps: (1) Raw material selection

[0059] Choose fresh and mildew-free sorghum as raw material;

[0060] (2) Raw material processing

[0061] The above-mentioned raw materials are pulverized, and the pulverization degree is 40 mesh;

[0062] (3) Moisturizer

[0063] Add 60% water by weight of the above raw materials, and keep stirring to make the raw materials absorb water evenly and sufficiently;

[0064] (4) Cooking

[0065] Add the moistened material into the steamer, and cook for 55 minutes at 118°C and 0.11 Mpa;

[0066] (5) mix music

[0067] Mix Daqu and water in the s...

Embodiment 3

[0080] A process for making vinegar and co-producing shiitake mushroom sauce using oats and shiitake mushrooms as fermentation auxiliary materials is characterized in that it includes a vinegar brewing process using oats and shiitake mushrooms as fermentation auxiliary materials; the vinegar brewing process using oats and shiitake mushrooms as fermentation auxiliary materials includes the following Steps: (1) Raw material selection

[0081] Choose fresh and mildew-free sorghum as raw material;

[0082] (2) Raw material processing

[0083] The above-mentioned raw materials are pulverized, and the pulverization degree is 45 mesh;

[0084] (3) Moisturizer

[0085] Add 61% water of the weight of the above raw materials, and keep stirring, so that the raw materials absorb water evenly and sufficiently;

[0086] (4) Cooking

[0087] Put the moistened material into the steamer, and steam for 57 minutes at 120°C and 0.12 Mpa;

[0088] (5) mix music

[0089] Mix Daqu and water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com