A kind of solid-state vinegar brewing method that improves the utilization rate of starch

A utilization rate, solid state technology, applied in the field of food condiments, can solve the problems of starch cannot be utilized, increase environmental burden, pollute environmental raw materials, etc., and achieve the effects of improving flavor and taste, improving starch utilization rate, and reducing starch content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

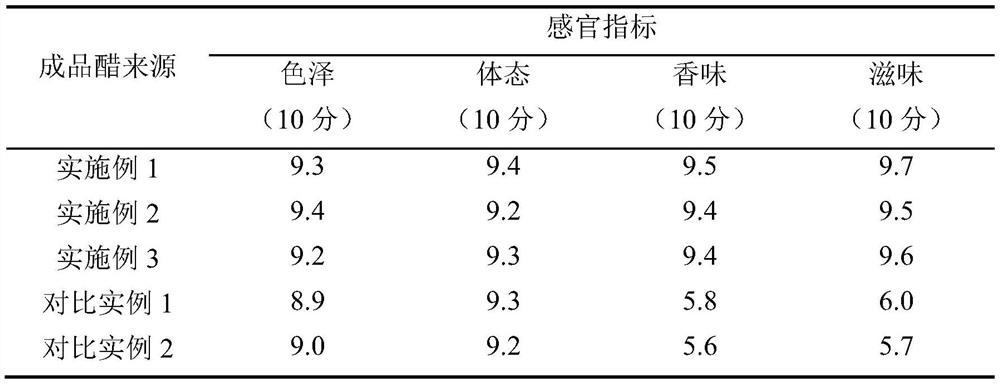

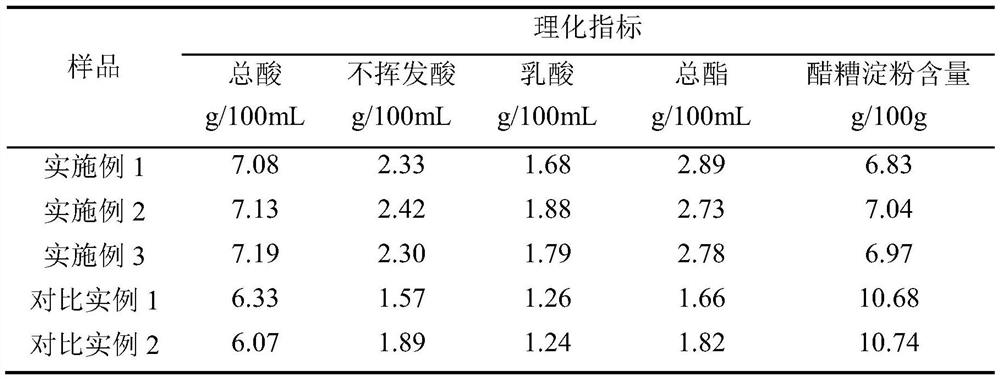

Embodiment 1

[0034] A kind of solid-state vinegar making method that improves starch utilization rate, comprises the following steps:

[0035] (1) Selection of raw and auxiliary materials: select fresh glutinous rice without mildew and deterioration, and select fresh bran and rice husks with golden color and no deterioration of mildew;

[0036] (2) Soaking and cooking: Pour the glutinous rice into the tank for soaking, the weight ratio of water and glutinous rice is 2.5:1, soak for 15 hours, then wash the glutinous rice until there is no white pulp, drain; then cook for 45 minutes , to obtain cooked glutinous rice;

[0037] (3) Cooling: Spread the cooked glutinous rice and cool it down to about 30°C;

[0038] (4) Saccharification: Put the cooled cooked glutinous rice in a container, add 1.5% wheat koji by weight of the glutinous rice and mix evenly before saccharification, and the saccharification time is 2 days to obtain a saccharification liquid;

[0039] (5) Alcoholic fermentation: ad...

Embodiment 2

[0045] (1) Selection of raw and auxiliary materials: select fresh glutinous rice without mildew and deterioration, and select fresh bran and rice husks with golden color and no deterioration of mildew;

[0046] (2) Soaking and cooking: Pour the glutinous rice into the tank for soaking, the weight ratio of water and glutinous rice is 2.7:1, soak for 14 hours, then wash the glutinous rice until there is no white pulp, drain; then cook for 48 minutes , to obtain cooked glutinous rice;

[0047] (3) Cooling: Spread the cooked glutinous rice and cool it down to about 28°C;

[0048] (4) Saccharification: Put the cooled cooked glutinous rice in a container, add 1.25% wheat koji by weight of the glutinous rice and mix it evenly before saccharification. The saccharification time is 3 days to obtain a saccharification liquid;

[0049] (5) Alcoholic fermentation: add 0.85% wine medicine by weight of glutinous rice and 140% water by weight of glutinous rice to the saccharification liquid,...

Embodiment 3

[0055] (1) Selection of raw and auxiliary materials: select fresh glutinous rice without mildew and deterioration, and select fresh bran and rice husks with golden color and no deterioration of mildew;

[0056] (2) Soaking and cooking: Pour the glutinous rice into the tank for soaking, the weight ratio of water and glutinous rice is 3:1, soak for 18 hours, then wash the glutinous rice until there is no white pulp, drain; then cook for 55 minutes , to obtain cooked glutinous rice;

[0057] (3) Cooling: Spread the cooked glutinous rice and cool it down to about 25°C;

[0058] (4) Saccharification: put the cooled cooked glutinous rice in a container, add 1.4% wheat koji by weight of the glutinous rice and mix evenly, then carry out saccharification, and the saccharification time is 3 days to obtain a saccharification liquid;

[0059] (5) Alcoholic fermentation: add 0.9% wine medicine by weight of glutinous rice and 140% water by weight of glutinous rice to the saccharification l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com