The method of a marine source Bacillus licheniformis for vinegar bioaugmentation

A Bacillus licheniformis, bioaugmentation technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effect of improving the quality of vinegar, improving product flavor, and increasing the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Screening of High-Producing Amylase Strains in Marine Sediments

[0035] (1) Pretreatment of marine sediment samples

[0036] Put 2g of marine sediment in 18mL seawater containing 5% skimmed milk, 10mM asparagine, 10mM glucose, 10mM fructose, and 10mM KCl, place the Erlenmeyer flask at 85°C for 10 minutes after heat shock, then place it on a shaker at 55°C, 200rpm enrichment culture for 7 days.

[0037] (2) Isolation and purification of strains

[0038] After the pretreatment, use a pipette to draw 0.2ml of the supernatant and spread it on the PYA, AMGM, Casein, BPGS medium and culture it at 55°C. Different colonies were selected by morphological observation for four-section line purification, and the purified strains were cultured on PYA medium for 1-3 days, and stored simultaneously in glycerol tubes (-80°C) and lyophilized tubes (4°C).

[0039] Separation medium (PYA): peptone 0.8%, yeast extract 0.3%, K 2 HPO40.1%, EDTA3.5mg, ZnSO 4 ·7H 2 O 3 mg, Fe...

Embodiment 2

[0047] Example 2: Preparation of high amylase-producing strain B.licheniformis CCTCC NO:M 2017209 lyophilized powder

[0048] (1) Activation culture of high amylase-producing strain B.licheniformis CCTCC NO:M 2017209

[0049] Put the bacterial powder of the strain B.licheniformis CCTCC NO:M 2017209 into 150mL liquid activation medium, and culture it on a shaker at 50°C for 40-48h to obtain the first-grade seed liquid; inoculate the first-grade seeds with 6% (v / v) Add the amount into 400mL liquid medium, and culture on a shaker at 50°C for 40-48h to obtain the secondary seed liquid;

[0050] The secondary seed solution was added to 6000 mL liquid medium according to the inoculum amount of 8% (v / v), and cultured on a shaker at 50° C. for 46-48 hours to obtain the tertiary seed solution.

[0051] Activation medium (Marine agar 2216E): yeast powder 0.1%, tryptone 0.5%, ferric citrate 0.1g / L, seawater 1L, pH 7.2-7.4.

[0052] (2) Cell collection

[0053] Pour the tertiary fermen...

Embodiment 3

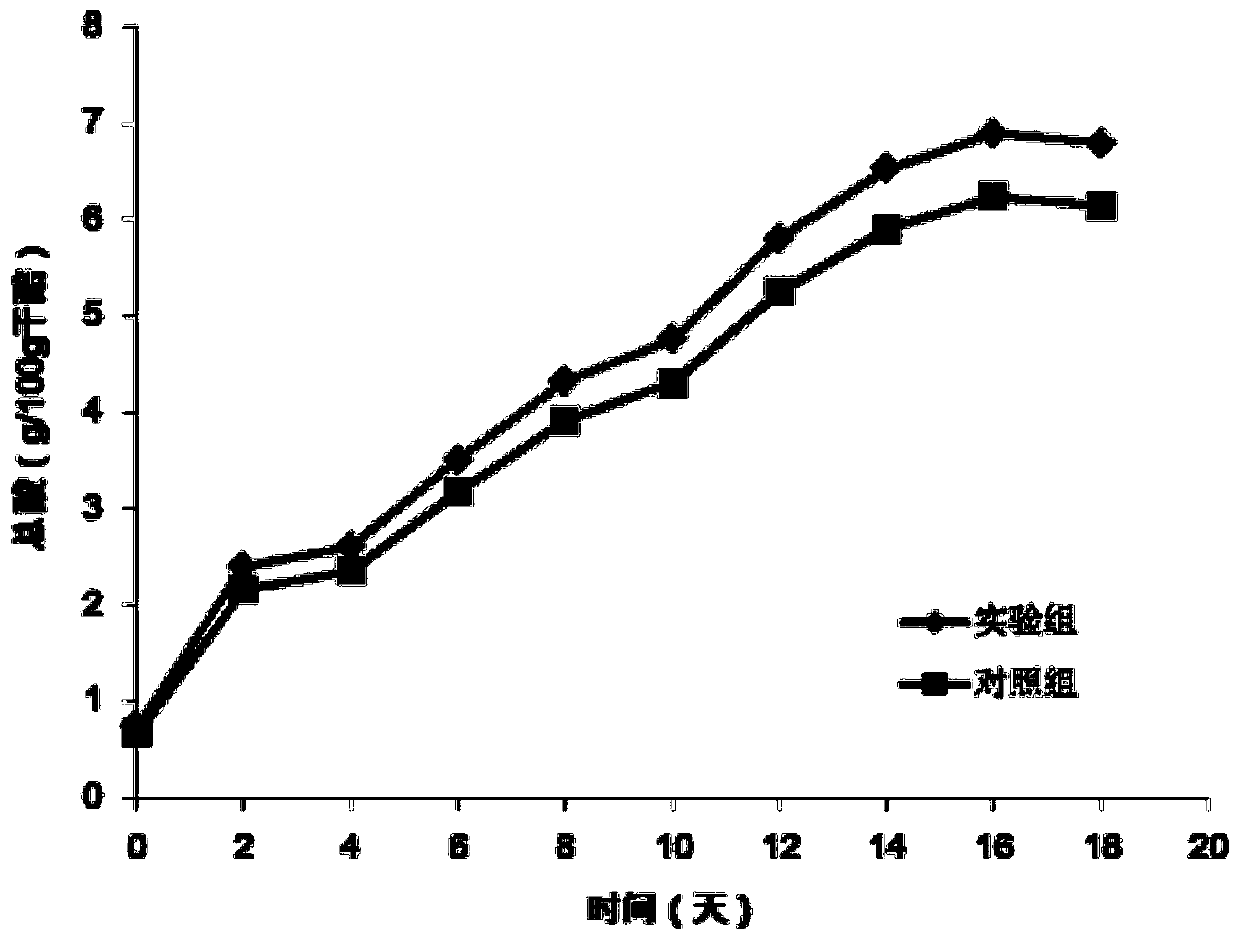

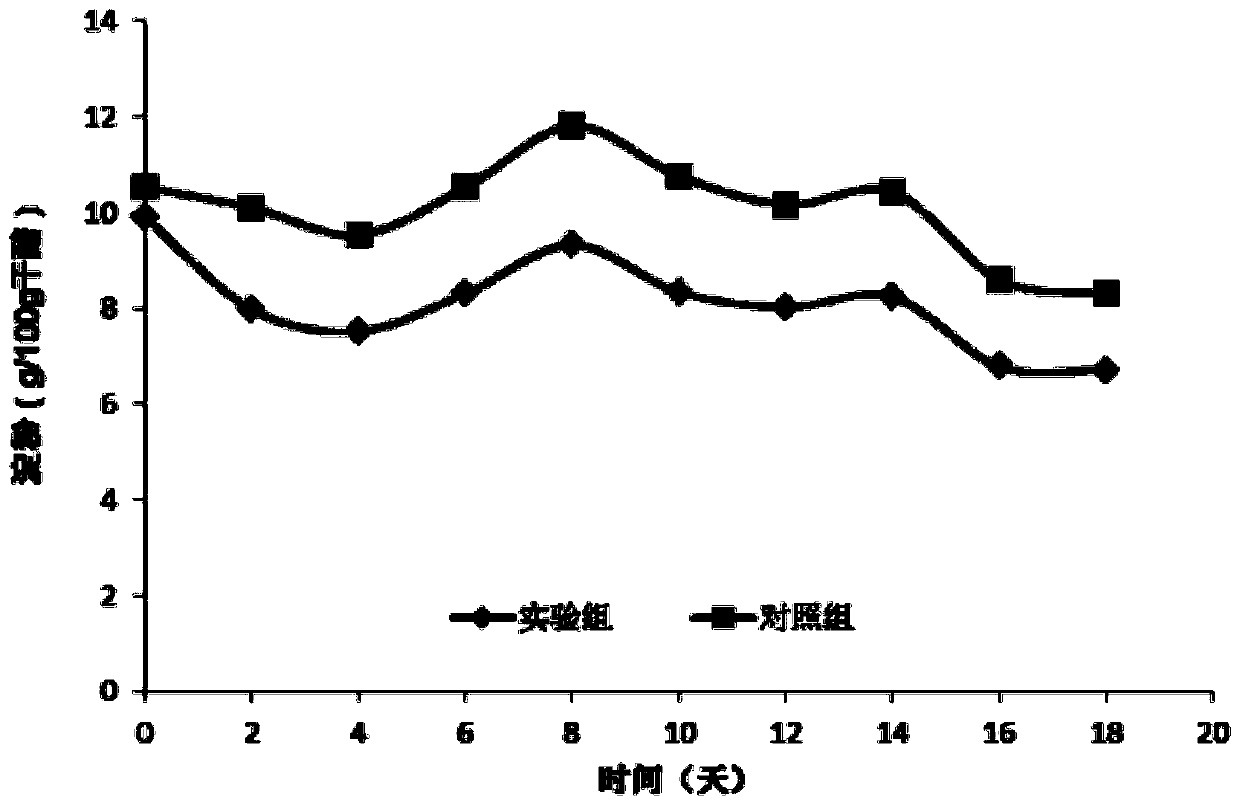

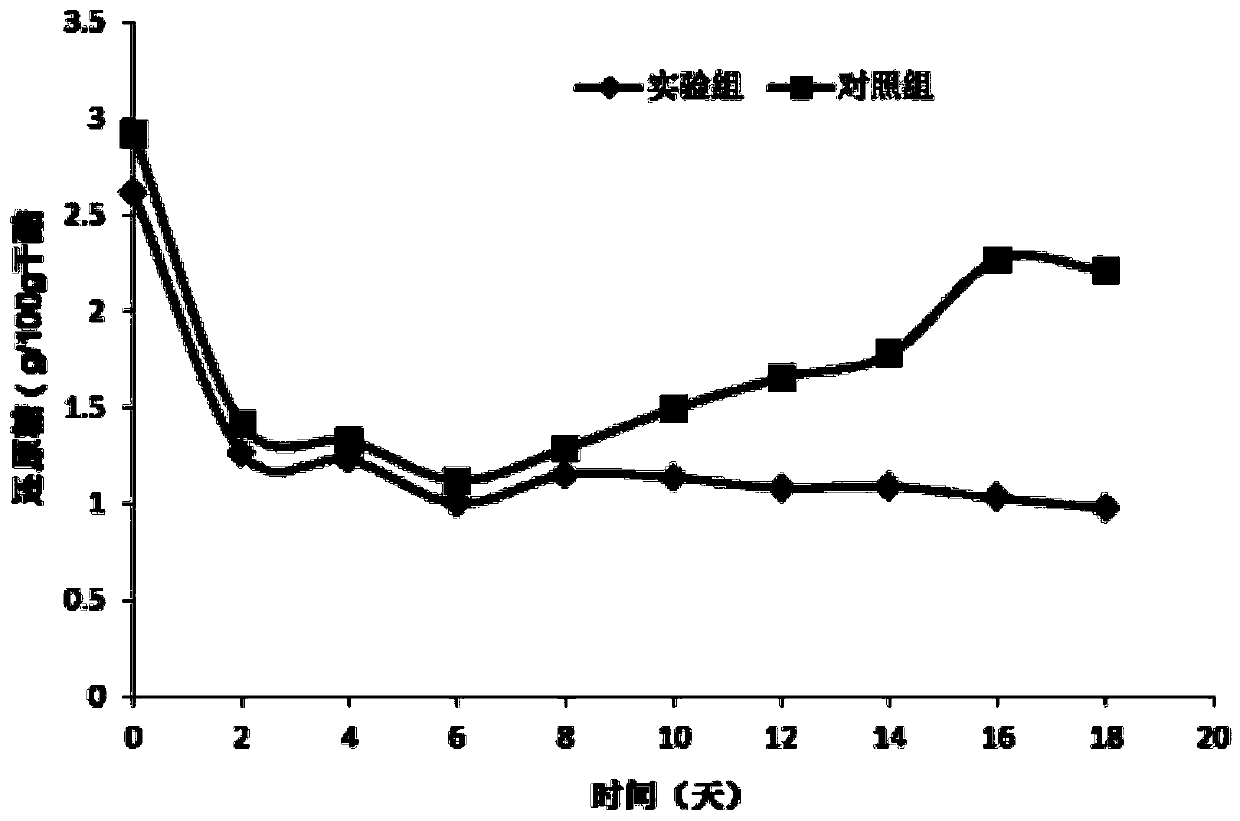

[0056] Embodiment 3: the bioaugmentation of vinegar fermentation process

[0057] (1) Raw material

[0058] The selected fermented vinegar raw material proportioning of the present embodiment is:

[0059] Wine mash: 130kg / cyl (alcohol content: 9.6, total acid: 4.4g / L); bran: 50kg / cyl; large bran: 24kg / cyl; water: 15kg / cyl; NaCl: 3kg / cyl.

[0060] (2) Traditional vinegar brewing process

[0061] [1] Add 130kg of wine mash and 50kg of bran into the cylinder, stir and mix.

[0062] [2] Add 8kg seed unstrained spirits in the cylinder.

[0063] [3] Heating stage: Rinse the fermented grains properly, add bran, and turn the fermented grains, but do not cut the bran down, and wait for the product temperature to rise above 40°C.

[0064] [4] Scooping stage: After the heating is completed, according to the product temperature, the bran is cut down, rinsed, added, and fermented every day. One or two days after the ladle starts, start to divide the vats. At this stage, the addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com