Method for preparing gamma-aminobutyric acid enriched vinegar

A technology of aminobutyric acid and sodium glutamate, which is applied in the fields of edible vinegar production and condiment brewing engineering, can solve the problems that cannot meet the needs of health care, achieve better and softer taste, increase lactic acid content, and inhibit miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

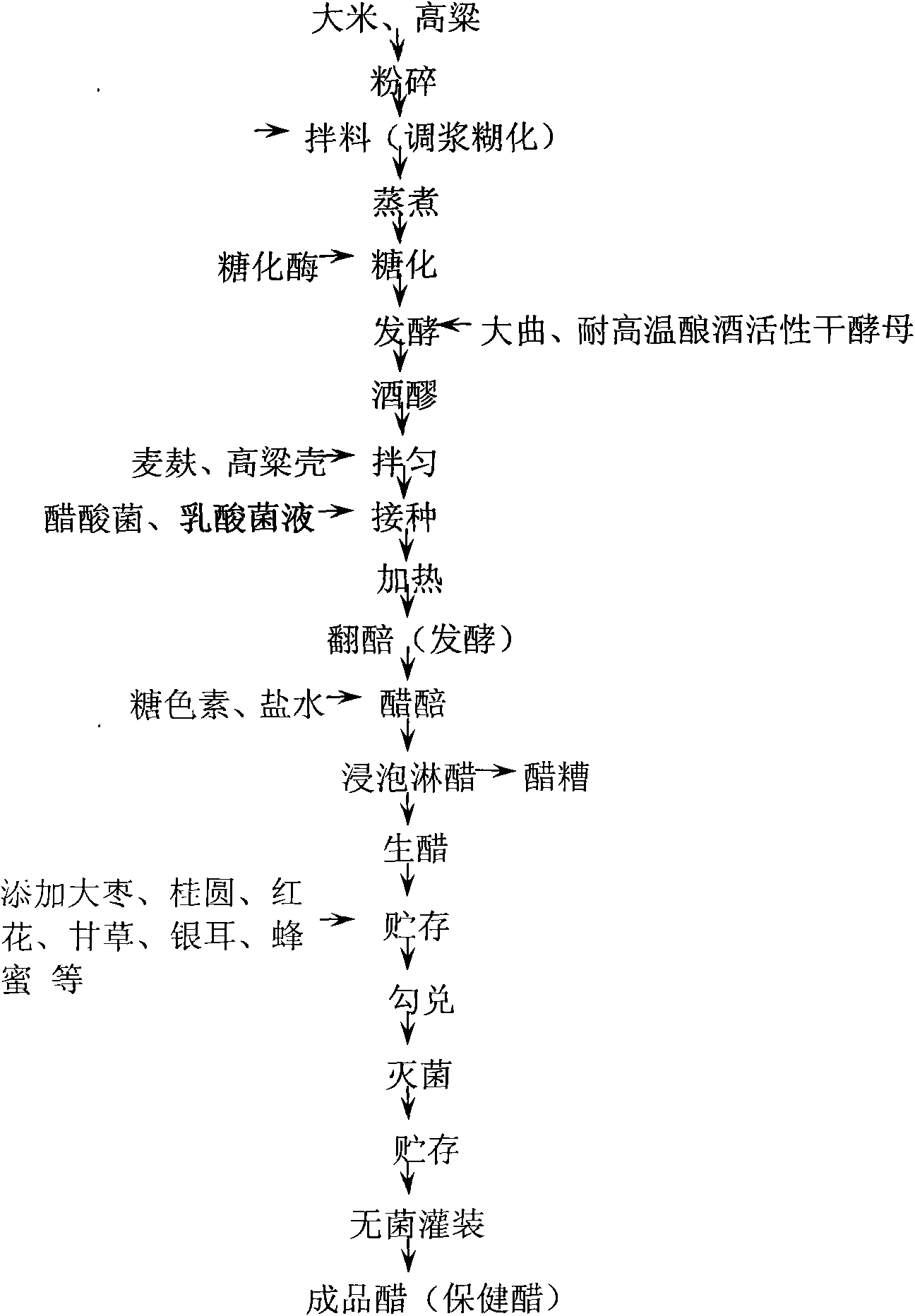

[0024] Embodiment one, in conjunction with Fig. 1

[0025] 1. The preparation process of lactic acid bacteria culture solution is:

[0026] (1) Activation of strains: Inoculate the preserved original species Lactobacillus brevis into 10 ml of MRS test tube culture medium, and culture at 30° C. for 24 hours. It can be transferred several times appropriately. This bacterial strain is Lactobacillus brevis (Lactobacillus brevis) preservation number TCCC13007 preserved in the Microbial Strain Preservation Management Center of Tianjin University of Science and Technology. Preservation address: No. 29, 13th Street, Tianjin TEDA Development Zone; postal code: 300457;

[0027] (2) First-level seed cultivation: Connect the above-mentioned test tube culture solution into a conical flask equipped with 200mL culture solution, and its medium composition is: glucose 20g / L, yeast extract 20g / L, sodium citrate 2g / L, acetic acid Sodium 2g / L diammonium citrate 2g / L, pH natural. Sterilize at ...

Embodiment 2

[0041] Grind the raw rice and sorghum rice into powder, add water to make a slurry, add 5-10U / g high-temperature α-amylase of raw material starch, heat up to 85°C-92°C to liquefy for 10-15min and then heat up Inactivate the enzyme at 100°C for 5 minutes, then cool down to 65°C, put it into the glucoamylase tank, and add 6~8U / g raw starch saccharification enzyme, saccharify at 63°C for 1.5h, cool down to 30°C, add 10% (v / v) of Daqu and 0.15% (v / v) of high temperature resistant active dry yeast (Saccharomy cerevisiae) cultivated Dajiufu, alcoholic fermentation at 33°C for 64h, to obtain 8% (v / v) Alcoholic alcohol mash. Put the wine mash into the acetic acid fermentation tank, and add auxiliary materials such as wheat bran, sorghum and 2L / 1000L of mature acetic acid bacteria (AS. The preparation process of the lactic acid bacteria culture solution expands the culture solution of lactic acid bacteria TCCC13007 containing 0.2g / L sodium glutamate, according to 2L / M 3 The amount of...

Embodiment 3

[0043] Grind the raw rice and sorghum rice into powder, add water and make a slurry, high temperature α-amylase, heat up and liquefy for 10-15 minutes, inactivate the enzyme at 100°C for 5 minutes, cool down to 65°C, add glucoamylase After 1.5 hours of saccharification, cool down to 30°C, add 10% (v / v) of Daqu and 0.2% (v / v) of Dajiufu expanded by high-temperature-resistant active dry yeast (Saccharomy Cerevisiae), and heat at 33°C Under alcoholic fermentation for 64h, the wine mash with 7.5% (v / v) alcohol concentration was obtained. Put the wine mash into the acetic acid fermentation tank, and add auxiliary materials wheat bran and sorghum according to the ratio of main material and auxiliary material as 1: 2.5, and add 0.4g / L-sodium glutamate lactic acid bacteria TCCC13007 culture solution, press 1.5L / M 3 Add the added amount of vinegar unstrained spirits, adjust the temperature at 26°C for lactic acid bacteria fermentation for 3 days, turn the unstrained spirits and cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com