Passion-fruit-and-longan fruit vinegar and making method thereof

A production method, the technology of passion fruit, applied in the preparation of vinegar, medical formula, medical preparations containing active ingredients, etc., can solve the problems of bad taste, low nutritional content, easy to produce precipitation, etc., to improve taste and nutrition Substance content, improvement of food flavor, effect of easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

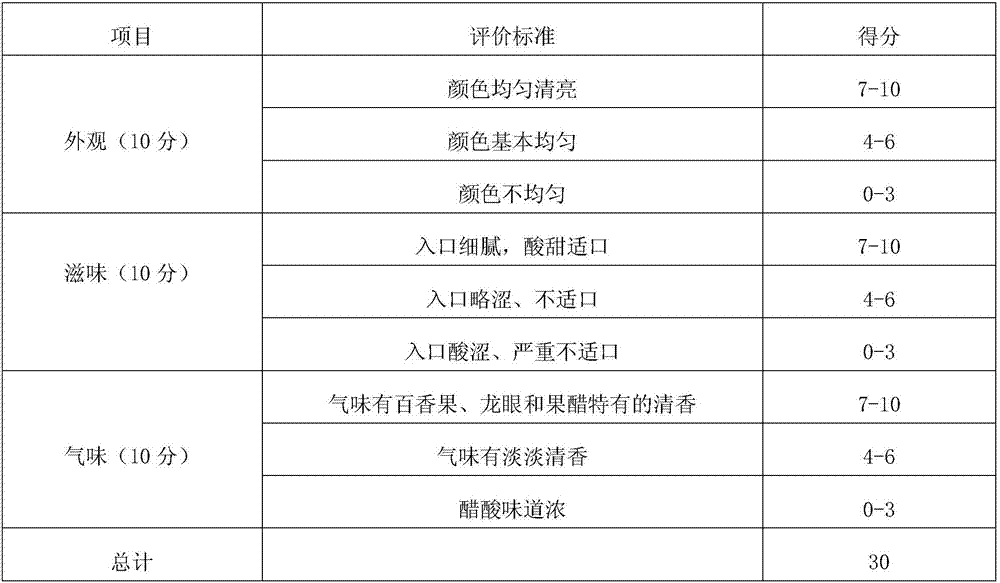

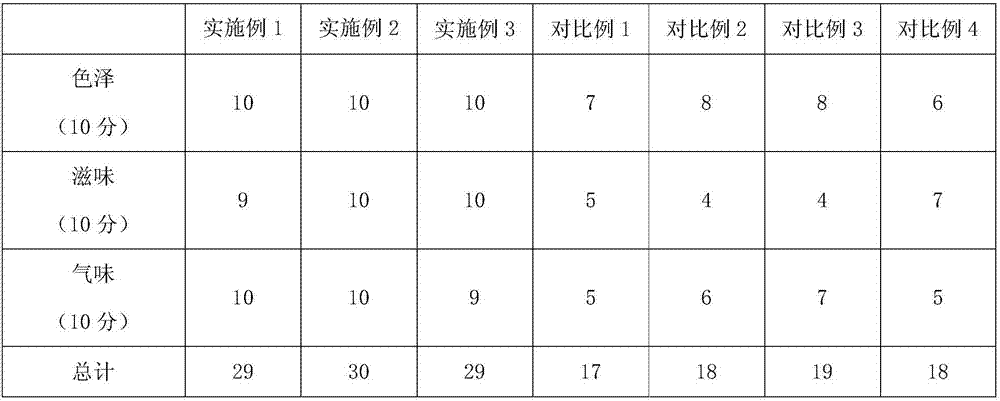

Examples

Embodiment 1

[0025] A preparation method of passion fruit and longan fruit vinegar, comprising the following steps:

[0026] (1) Select ripe, full-bodied passion fruit as a raw material, after cleaning it, separate the passion fruit husk from the substance in the husk for subsequent use, and cut the passion fruit husk into 1-2cm segments for subsequent use; Add acid protease to the cut passion fruit husk, treat it at a temperature of 38°C for 20 minutes, and then treat it with 250MPa instantaneous high pressure for 10s to obtain a solid-liquid mixture; wherein, the amount of acid protease used is 0.03% by weight;

[0027] (2) Mix and grind corn and sorghum according to the mass ratio of 1:3, and steam to obtain mixture a. When the mixture a is air-dried to 37-38°C, add yeast and mix thoroughly. Stir once after 16 hours, and after 2 days Add acetic acid bacteria agent according to the dosage of 0.010g / 100g, stir evenly, mix in 5wt% mixture a quality chaff chaff after interval 5d, stir once...

Embodiment 2

[0033] A preparation method of passion fruit and longan fruit vinegar, comprising the following steps:

[0034](1) Select ripe, full-bodied passion fruit as a raw material, after cleaning it, separate the passion fruit husk from the substance in the husk for subsequent use, and cut the passion fruit husk into 1-2cm segments for subsequent use; Add acid protease to the cut passion fruit husk, treat it at a temperature of 39°C for 25 minutes, and then treat it with 280MPa instantaneous high pressure for 20s to obtain a solid-liquid mixture; wherein, the amount of acid protease used is 0.04% by weight;

[0035] (2) Mix and crush corn and sorghum according to the mass ratio of 1:4, and steam to obtain mixture a. When the mixture a is air-dried to 37-38°C, add yeast and mix thoroughly. Stir once after 18 hours, and after 3 days Add acetic acid bacteria agent according to the dosage of 0.012g / 100g, stir evenly, mix 6wt% chaff of mixture a quality after an interval of 6d, stir once ...

Embodiment 3

[0041] A preparation method of passion fruit and longan fruit vinegar, comprising the following steps:

[0042] (1) Select ripe, full-bodied passion fruit as a raw material, after cleaning it, separate the passion fruit husk from the substance in the husk for subsequent use, and cut the passion fruit husk into 1-2cm segments for subsequent use; Add acid protease to the cut passion fruit husk, treat it at a temperature of 38.5°C for 23 minutes, and then treat it with an instantaneous high pressure of 270MPa for 15s to obtain a solid-liquid mixture; wherein, the amount of acid protease used is 0.035wt% of;

[0043] (2) First mix corn and sorghum according to the mass ratio of 1:3.5, and then steam them to obtain mixture a. When the mixture a is air-dried to 37-38°C, add yeast and mix thoroughly, stir once after 17h, 2.5d Finally, according to the dosage of 0.011g / 100g, add acetic acid bacteria agent, stir evenly, mix 5.5wt% rice bran of the quality of mixture a after an interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com