Mode for inpouring fuel into future tokamak type thermonuclear reactor power station

A fusion reactor and power station technology, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve the problems of physical and chemical changes in liquid fuels, low efficiency, and impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

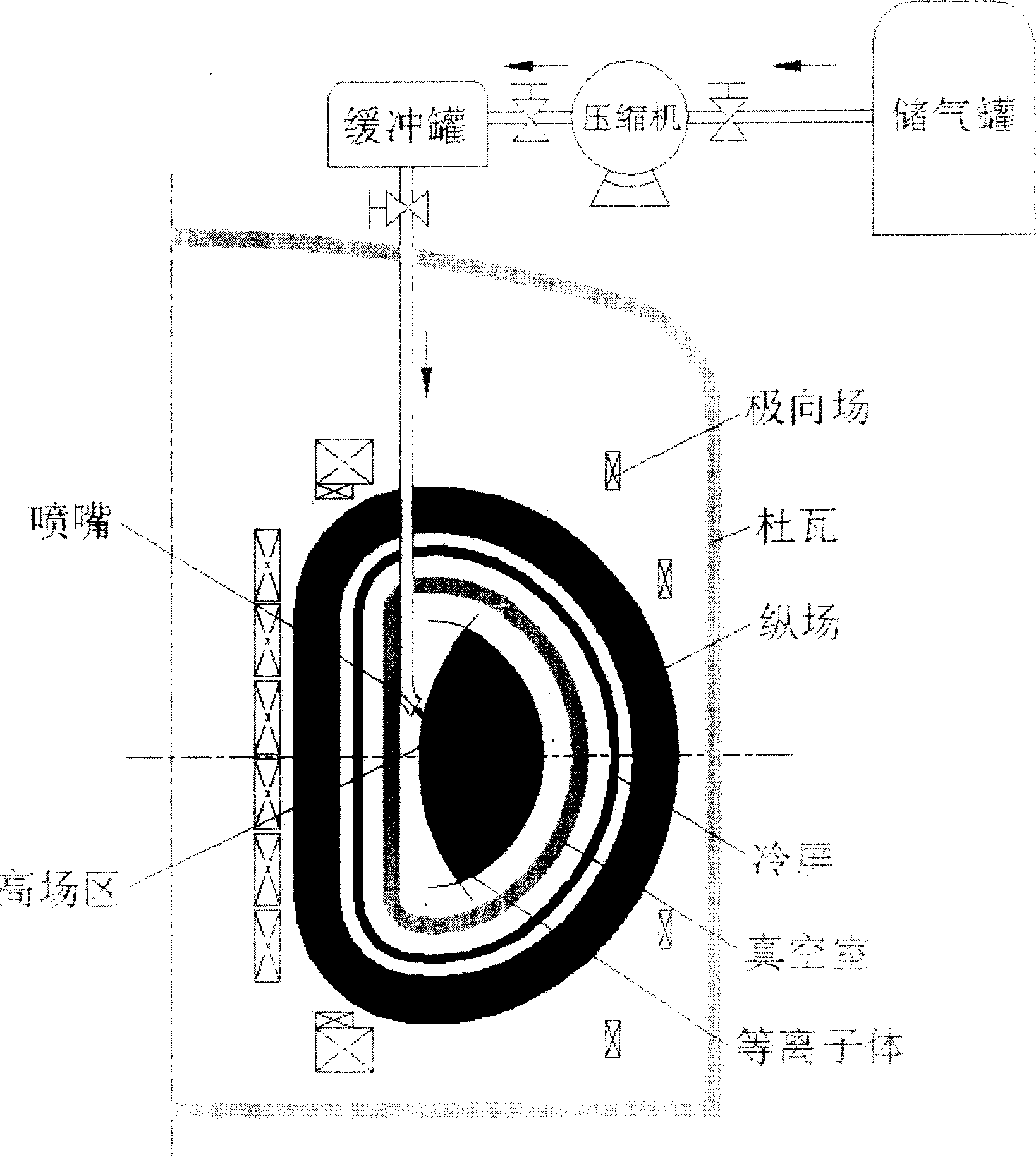

[0016] see figure 1 ~ Figure 6.

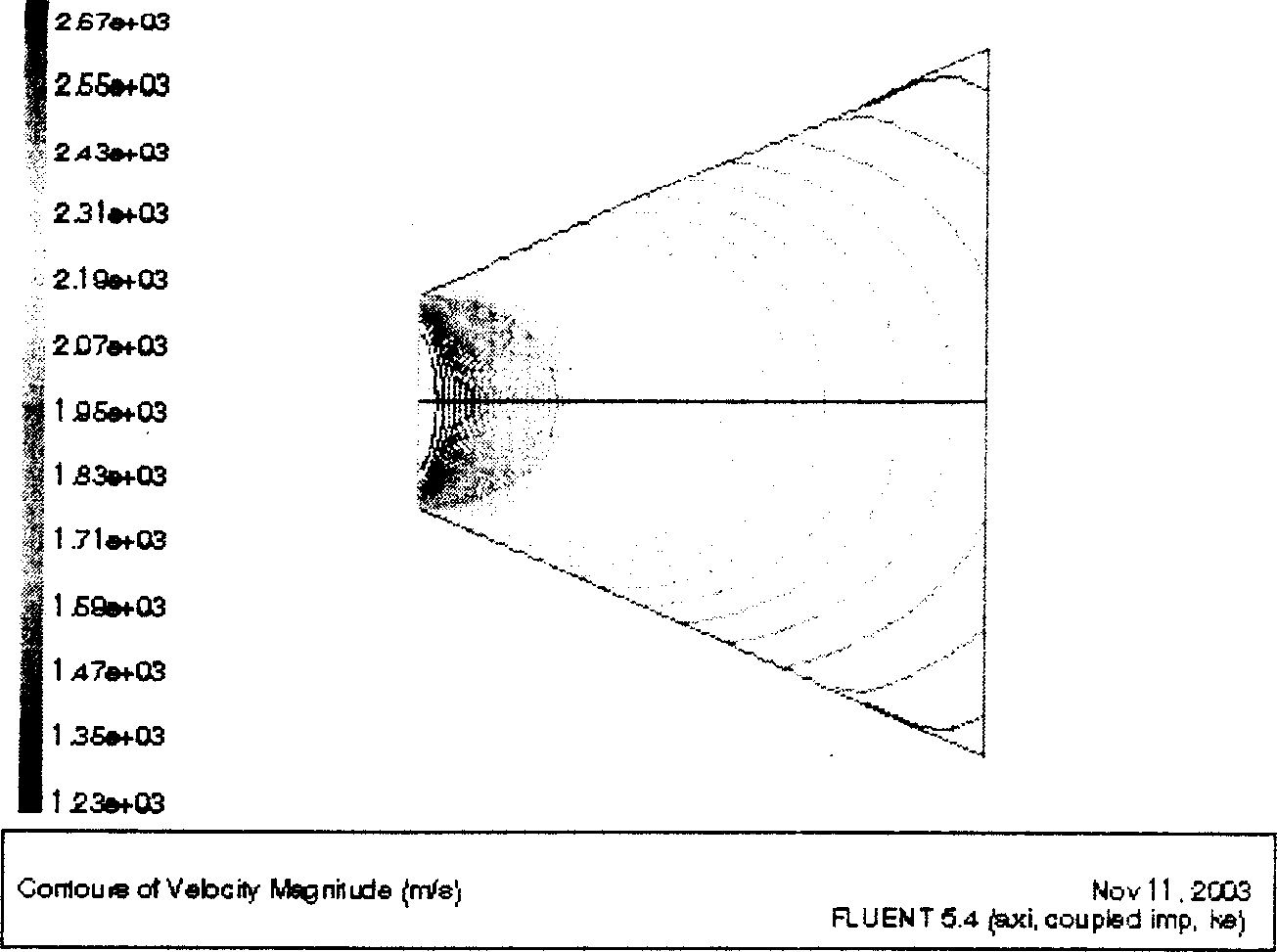

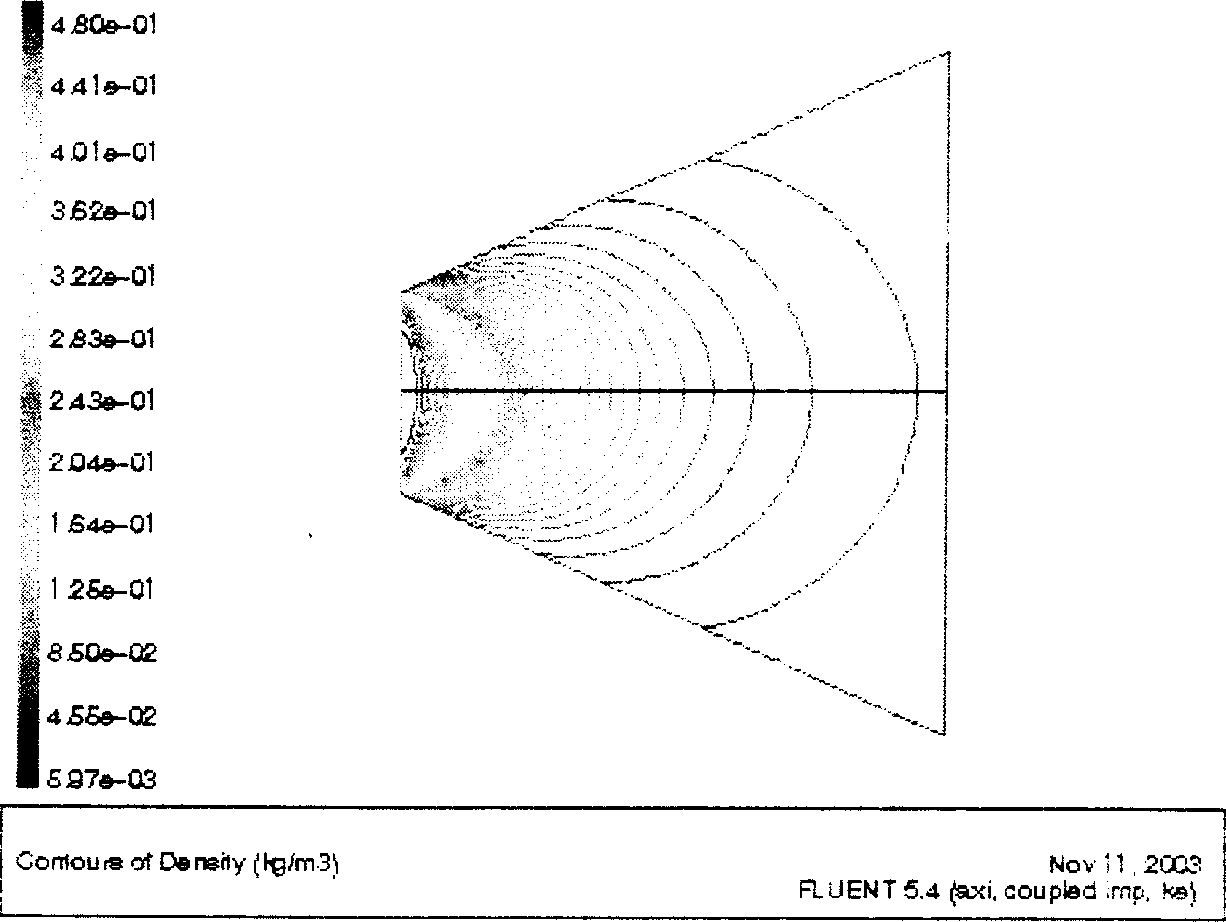

[0017] The gas path process of the fuel injection method of the Tokamak fusion reactor power station is: first, the fusion reactor fuel gas is stored in a low-pressure gas storage tank, and then passes through the compressor. The gas flow pressure is raised to 100 atmospheres, stored in the buffer tank, and finally by Valve control, through the Lava nozzle, the airflow passes through the nozzle shrinkage neck, first compressed, and then rapidly expanded, the maximum speed airflow can reach 2670m / s, the Mach number reaches 5, and enters the plasma high field area. The plasma distance from the nozzle to the edge of the plasma area is 20cm, the distance from the buffer tank to the nozzle is 5m, and the pipe diameter is 10mm.

[0018] For the plasma and its edge area, the sound velocity of particles is used. Its value is not 340m / s in the air, which changes with the temperature and vacuum of the plasma area. In the central area of the plasma, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com