Focusing and leveling sensor for projection photo-etching machine

A focusing, leveling, and sensor technology, applied in the direction of optomechanical equipment, optics, instruments, etc., can solve the problems that affect the measurement accuracy, cannot be directly measured, and the distance between the measurement spots is small, so as to increase the measurement area and reduce mutual interaction. Overlapping areas, improving the effect of focusing and leveling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

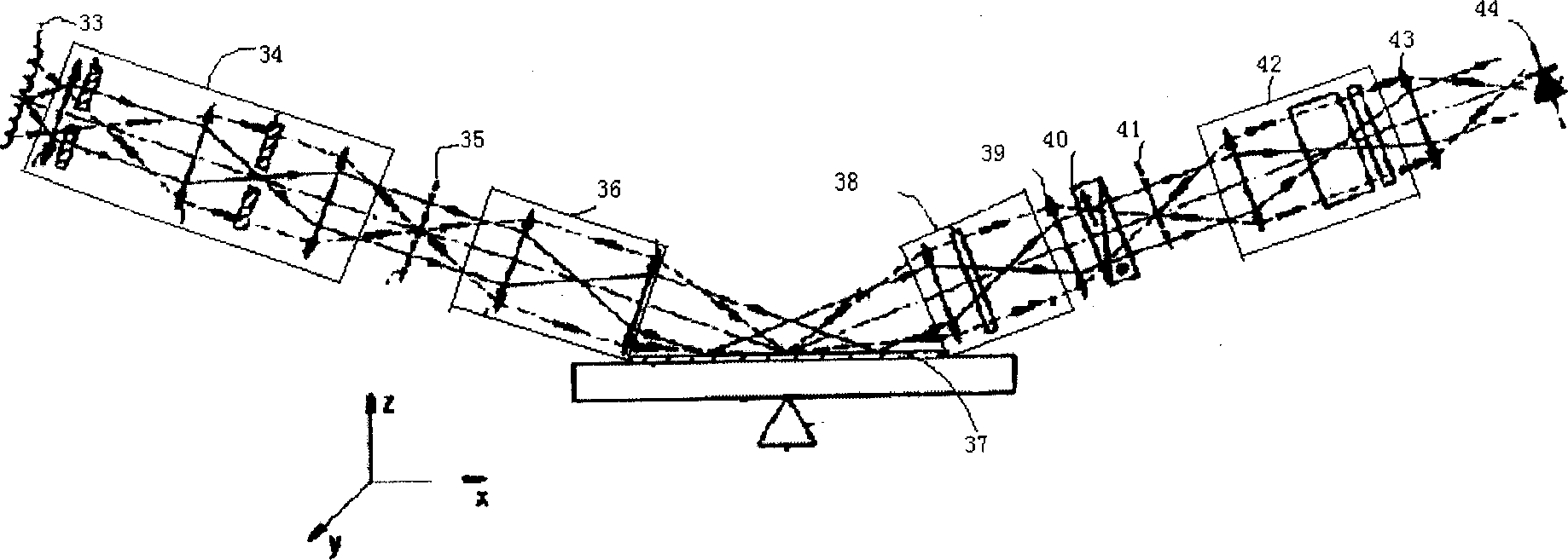

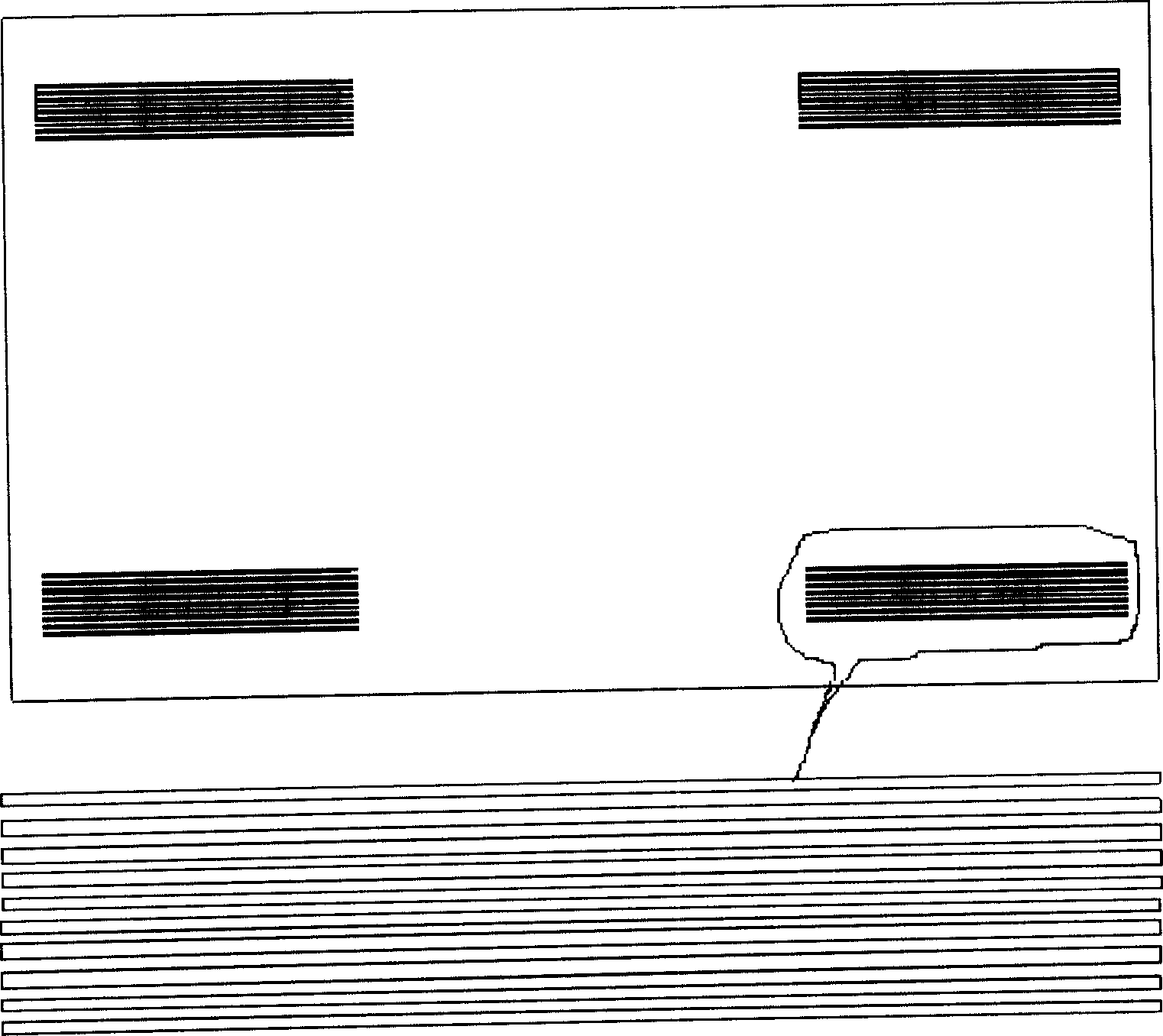

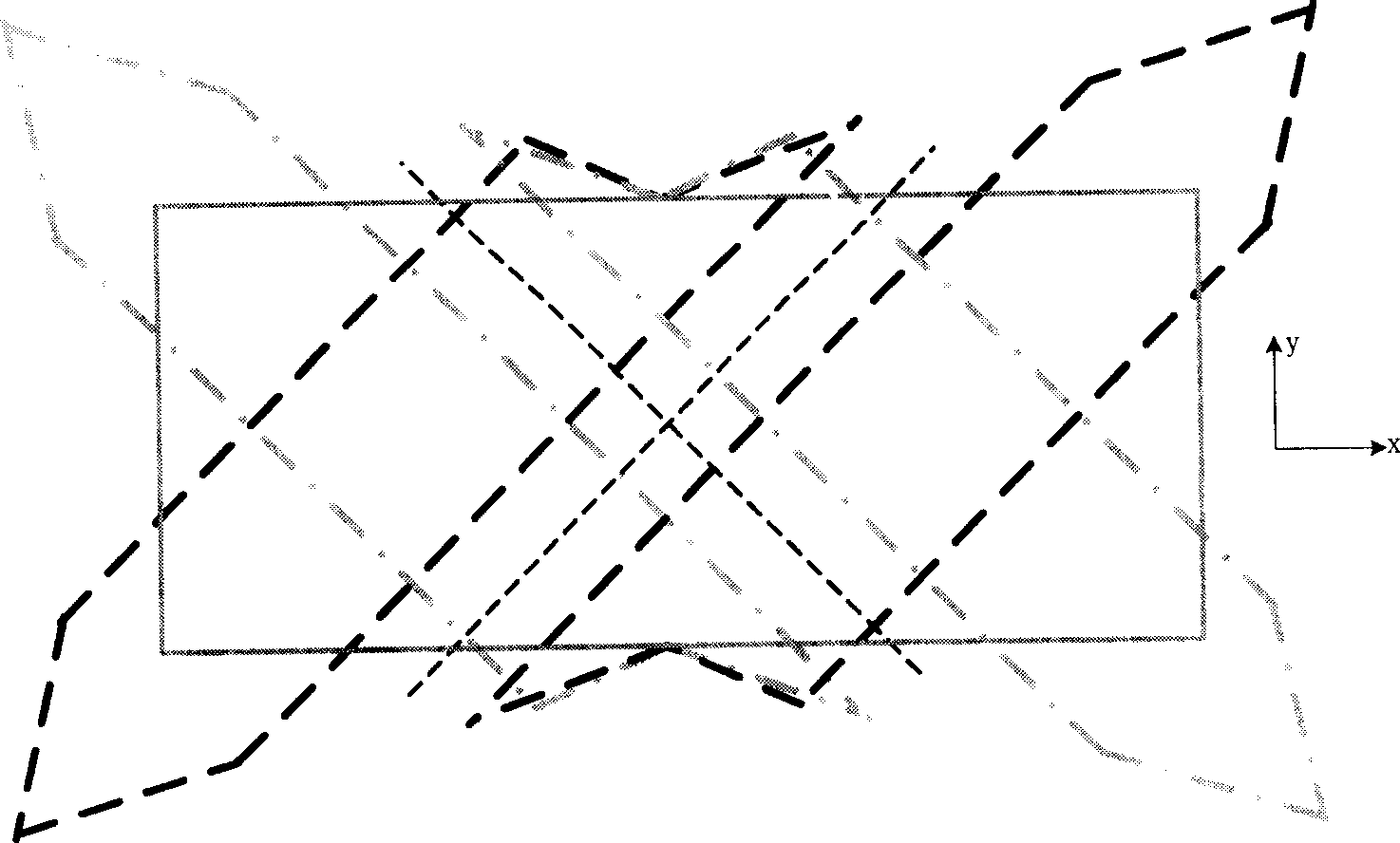

[0041] The present invention is applied in such as Figure 7 shown in the projection lithography machine. The lithography machine mainly includes a laser 1 for generating an exposure beam, an illumination system 2 including a variable slit 3 for controlling the size of the exposure field of view, a projection objective lens 6 for imaging a mask pattern 4 on a substrate 7, carrying a mask 4 and A mask table 5 capable of precise positioning, a workpiece table 8 capable of carrying a substrate 7 and capable of precise positioning, and a focusing and leveling sensor 9 for measuring the height and inclination of the substrate surface relative to the best focal plane of the projection objective lens.

[0042] Figure 7 The focusing and leveling sensor 9 in is the focusing and leveling sensor described in the present invention. The focusing and leveling sensor includes two branches perpendicular to each other, and each branch includes two measurement optical paths and two reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com