Metal based board with copper foil coated compound medium

A metal matrix composite, copper clad laminate technology, applied in metal layered products, layered products, chemical instruments and methods, etc., can solve problems such as the inability to meet the needs of high-performance metal matrix composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

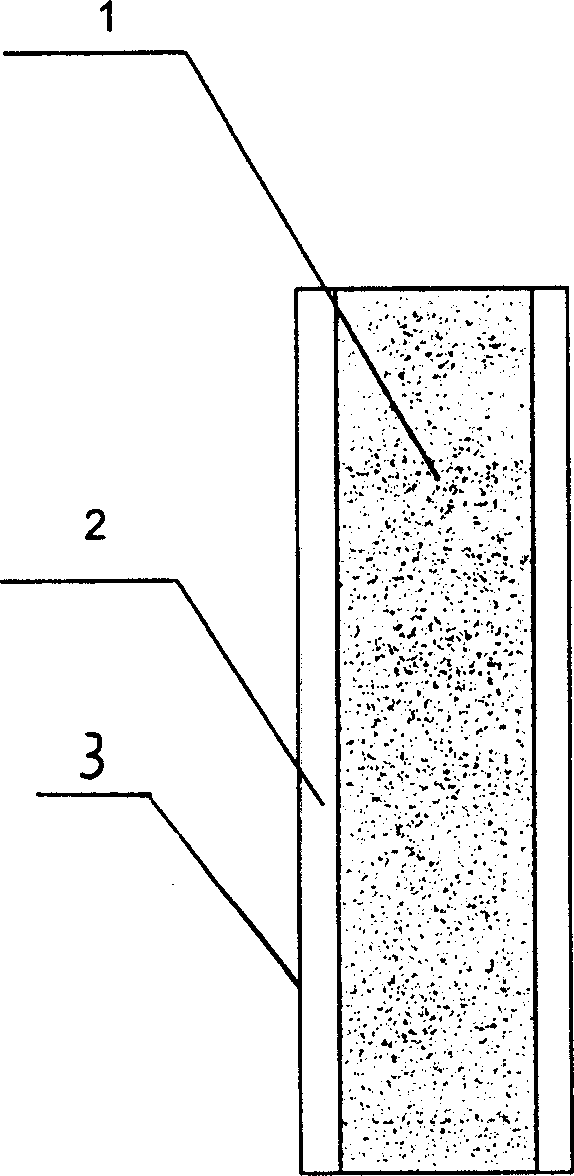

[0009] Embodiment 1, as shown in the accompanying drawings, the preparation process is to mix raw materials such as tetrafluoroethylene with ceramics or rutile, or mix polytetrafluoroethylene, ceramics and rutile in proportion, dry several times, and sinter to form a composite material layer; proportioning copper, aluminum or iron in proportion, treating the copper, aluminum or iron-based surface, bonding composite material layer 2 and copper, aluminum or iron 1 with thermally conductive adhesive powder, composite material layer and copper foil 3 Perform one compression molding. The weight ratio of the three layers is controlled in the range of metal base:composite material:copper foil=4-7:2-5:0.1-2. The weight ratio of polytetrafluoroethylene to ceramics and rutile, single ceramics or single rutile is controlled in the range of 5-7:2-5.

Embodiment 2

[0010] Embodiment 2. The composite material layer 2 is glass cloth with polytetrafluoroethylene coating, and the polytetrafluoroethylene coating of the glass cloth is several to dozens of layers according to requirements. All the other preparation processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com