Optical color variable pigment with near-infrared transmission feature and preparation process thereof

A color-changing pigment, infrared transmission technology, applied in the direction of pigment paste, etc., can solve the problem of lack of infrared transmission ability, etc., to achieve the effect of improving anti-counterfeiting ability and inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation of meltable liquid crystal polymer: 65g 2-hydroxyl-6-naphthoic acid, 130g p-hydroxybenzoic acid, 62g 4,4'-dihydroxybiphenyl, 70g (+)-camphoric acid and 210g acetic anhydride in proportion Added to the reactor, flushed with nitrogen flow. The mixture was rapidly heated to 140°C and held at this temperature for 30 minutes. The temperature was then raised to 320°C and the melt was held at this temperature for 15 minutes. From about 220°C, acetic acid starts to evaporate. The nitrogen flush was then stopped and vacuum was applied. The melt was stirred for 30 minutes under reduced pressure (approximately 5 mbar). The product was placed in a nitrogen atmosphere and cooled to room temperature to obtain a meltable polymer liquid crystal.

Embodiment 2

[0017] Preparation of a mixture containing energy-polymerizable liquid crystal monomers:

[0018] 1. Nematic liquid crystal monomer 75g:

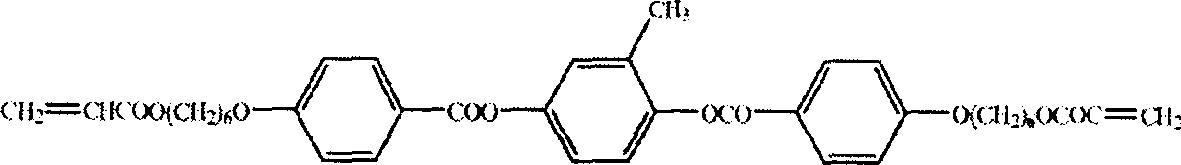

[0019]

[0020] 2. Monomer with chiral structure: cholesteryl acrylate 28g

[0021] 3. Photoinitiator 907 (from Ciba) 5g

[0022] B, Heliogen Blue L 7080 (from BASF company) 4g

[0023] C. Everlasting Red FBB (from Lily Chemical) 6g

[0024] D. Everlasting Yellow HR02 (from Baihe Chemical Industry) 3g

[0025] E. Chloroform 15g

[0026] Put the above 8 kinds of compounds into the planetary mixer according to the corresponding proportion, and carry out high-speed stirring and mixing to obtain a monomer mixture capable of energy polymerization.

Embodiment 3

[0028] 8.5 g of the meltable polymer liquid crystal produced in Example 1 and 1.5 g of HeliogenBlue L 6975F (from BASF) were mixed and extruded in a twin-screw extruder at 230° C. Put the extruded material into the granulator, carry out coarse crushing, and crush it into a particle size of about 2mm. Then the coarsely pulverized product is added to a jet mill for ultrafine pulverization to obtain a pigment with a particle size of about 15 microns. The pigment has a distinct golden-green luster under vertical observation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com