Al-Mg catalyst and catalytic synthesis process of alkoxyl carboxylate ether

A technology of catalyst and alkyl carboxylate, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex catalyst preparation process and increased cost, and achieve simple and low-cost preparation process. The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

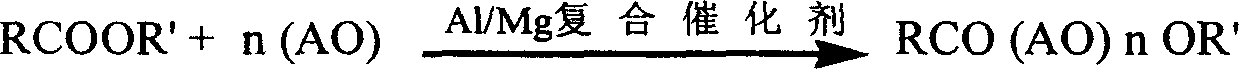

Method used

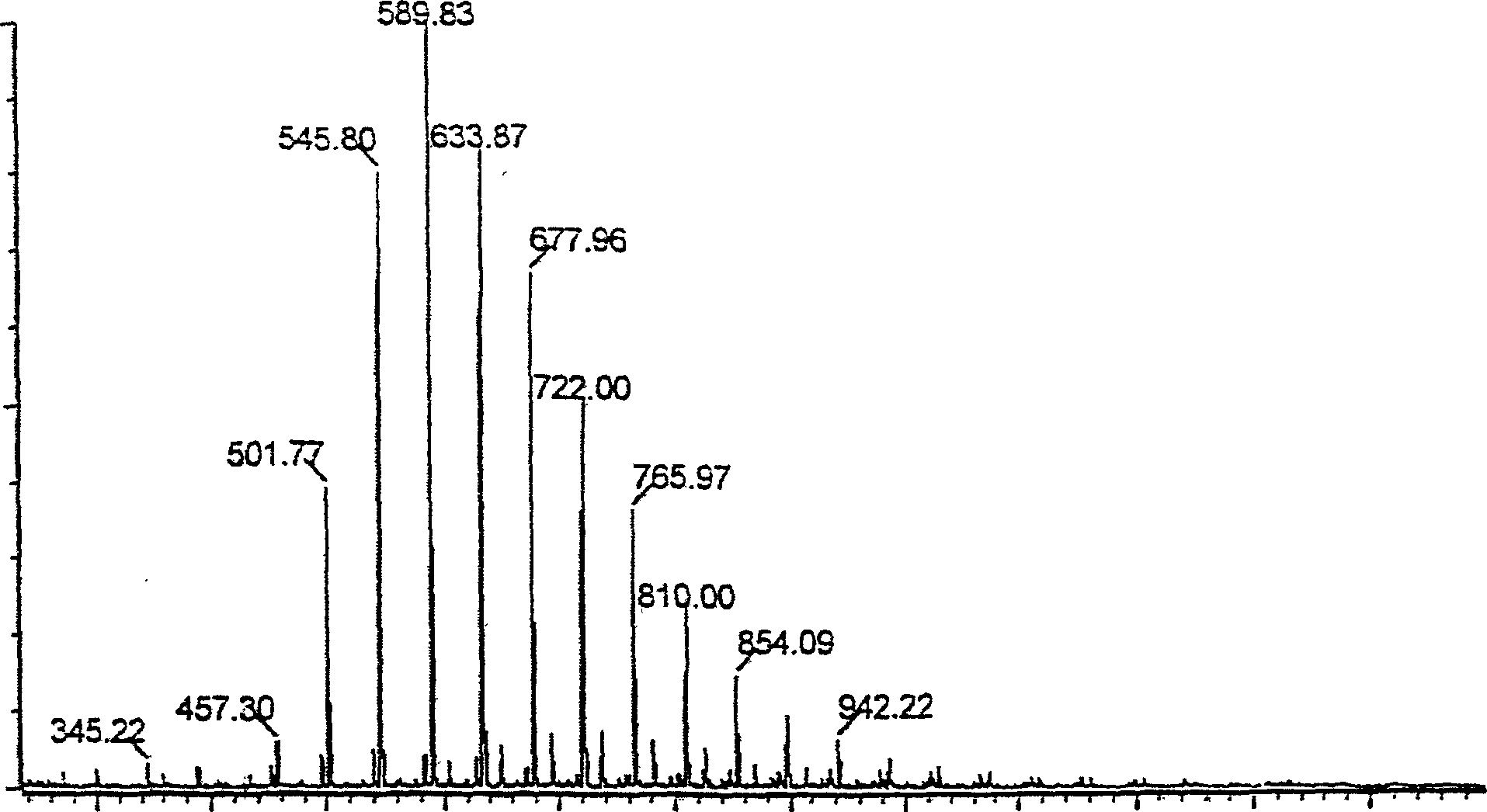

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of Aluminum-Magnesium Inorganic Composite Catalyst 1

[0018] Mix and grind 0.01mol aluminum nitrate, 0.005mol magnesium phosphate and 0.1mol magnesium oxide, add 1000ml deionized water to fully disperse, add 0.1mol sodium hydroxide and 0.01mol sodium carbonate under stirring, raise the temperature to 65°C and continue stirring for 24 hours. After filtering, dry in an oven above 120°C until no more weight loss, and set aside. The catalytic activity of the obtained aluminum-magnesium inorganic composite catalyst was 1.72gEO / gCat / min.

Embodiment 2

[0019] Example 2 Preparation of Aluminum-Magnesium Inorganic Composite Catalyst 2

[0020] Mix and grind 0.01mol aluminum carbonate, 0.1mol magnesium oxide and 0.18mol alumina, add 1000ml deionized water to fully disperse, add 0.09mol sodium hydroxide and 0.01mol sodium carbonate while stirring, raise the temperature to 50°C and continue stirring for 48 hours. After filtering, dry in an oven above 120°C until no more weight loss, and set aside.

Embodiment 3

[0021] Example 3 Preparation of Aluminum-Magnesium Inorganic Composite Catalyst 3

[0022] Mix and grind 0.01mol aluminum carbonate, 0.01mol magnesium chloride, 0.2mol magnesium oxide and 0.05mol aluminum oxide, add 1000ml deionized water to fully disperse, add 0.08mol sodium hydroxide and 0.015mol sodium carbonate under stirring, heat up to 55°C and continue Stir for 48 hours. After filtering, dry in an oven above 120°C until no more weight loss, and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com