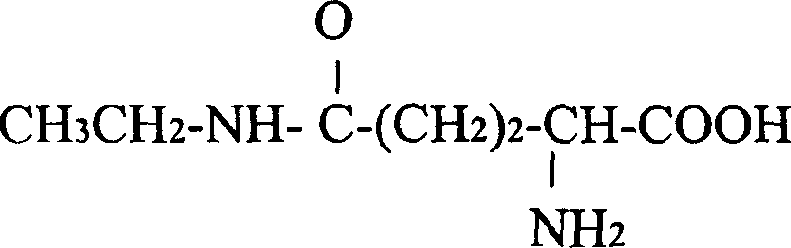

Theanine preparing process

A technology of theanine and pyroglutamic acid, which is applied in the direction of organic chemistry, can solve the problems of large investment in equipment and high requirements for reaction conditions, and achieve the effect of small investment in equipment, low requirements for reaction conditions, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

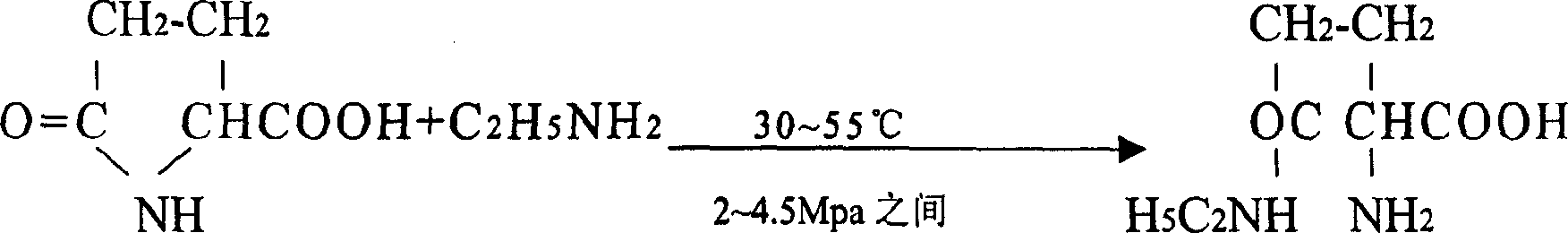

Method used

Image

Examples

example 1

[0018] Step 1: Put 50kg of L-pyroglutamic acid and 100kg of anhydrous ethylamine into a 200-liter reactor. In a closed state, stir and heat up. The temperature is controlled at about 35°C and the pressure is about 2.5Mpa. React 96 Hours, after the reaction is over, distill and recover ethylamine in a vacuum state, add absolute ethanol after cooling to room temperature, stir and heat up to reflux for 50 minutes, cool to 10°C to crystallize, and centrifuge to obtain L-theanine The crude product is about 15kg (wet product).

[0019] Step 2: Put 15kg of the L-theanine crude product obtained in step 1 and 120kg of absolute ethanol into a 200-liter reactor, the weight ratio of the two is 1:8, heat up to reflux for 50 minutes under stirring, and cool to 10°C, centrifuge to remove the material, and dry to obtain about 10kg of L-theanine high-quality goods. Calculated by solid L-pyroglutamic acid, the yield of L-theanine refined product is about 20%, and the purity of the obtained pro...

example 2

[0021] Step 1: Put 50kg of L-pyroglutamic acid and 200kg of anhydrous ethylamine into a 500-liter reactor, heat up in a closed state with stirring, and control the temperature between 50 and 55°C. Between 4 and 4.5Mpa, react for about 72 hours. After the reaction is over, distill and recover ethylamine to dryness under vacuum. After cooling to room temperature, add absolute ethanol, stir and heat up to reflux for 30 minutes, and cool to 5°C to crystallize , and centrifuged to get about 16kg of L-theanine crude product (wet product).

[0022] Step 2: Put 16kg of the L-theanine crude product obtained in step 1 and 80kg of absolute ethanol into a 200-liter reactor, the weight ratio of the two is 1:5, heat up to reflux under stirring, and cool to reflux for 50 minutes. Centrifuge at 5°C and dry to obtain about 11kg of fine L-theanine.

[0023] Calculated by solid L-pyroglutamic acid, the yield of L-theanine refined product is about 22%, and the purity is above 98%, which is deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com