Transparent polymer non-aqueous proton conducting material and its preparing method

A transparent polymer, proton-conducting technology, applied in the field of polymer materials and electrochemical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The raw materials used are as follows:

[0021] Polyvinyl alcohol, the number average molecular weight Mn is 17200, the product of Aldrich company.

[0022] Imidazole is a product of Shanghai Runjie Chemical Reagent Co., Ltd.

[0023] 85wt% phosphoric acid, product of Shanghai United Chemical Plant.

[0024] The ratio of raw materials used is as follows:

[0025] Polyvinyl alcohol (MW=17200) 15 parts (number of moles of repeating units)

[0026] 0.5 part of imidazole (number of moles)

[0027] Phosphoric acid 1 part (moles)

[0028] Sample preparation:

[0029] According to the above ratio, phosphoric acid and imidazole were dissolved in deionized water, and stirred at a constant temperature of 90°C for 4 hours to prepare imidazolium phosphate. Dissolve polyvinyl alcohol in deionized water, and stir with a magnetic stirrer at a constant temperature of 100°C until the PVA is completely dissolved to obtain a transparent and uniform viscous li...

Embodiment 2

[0035] The ratio of raw materials used is as follows:

[0036] 15 parts of polyvinyl alcohol (Mn=17200) (number of moles of repeating units)

[0037] 1 part of pyrazole (number of moles)

[0038] Phosphoric acid 1 part (moles)

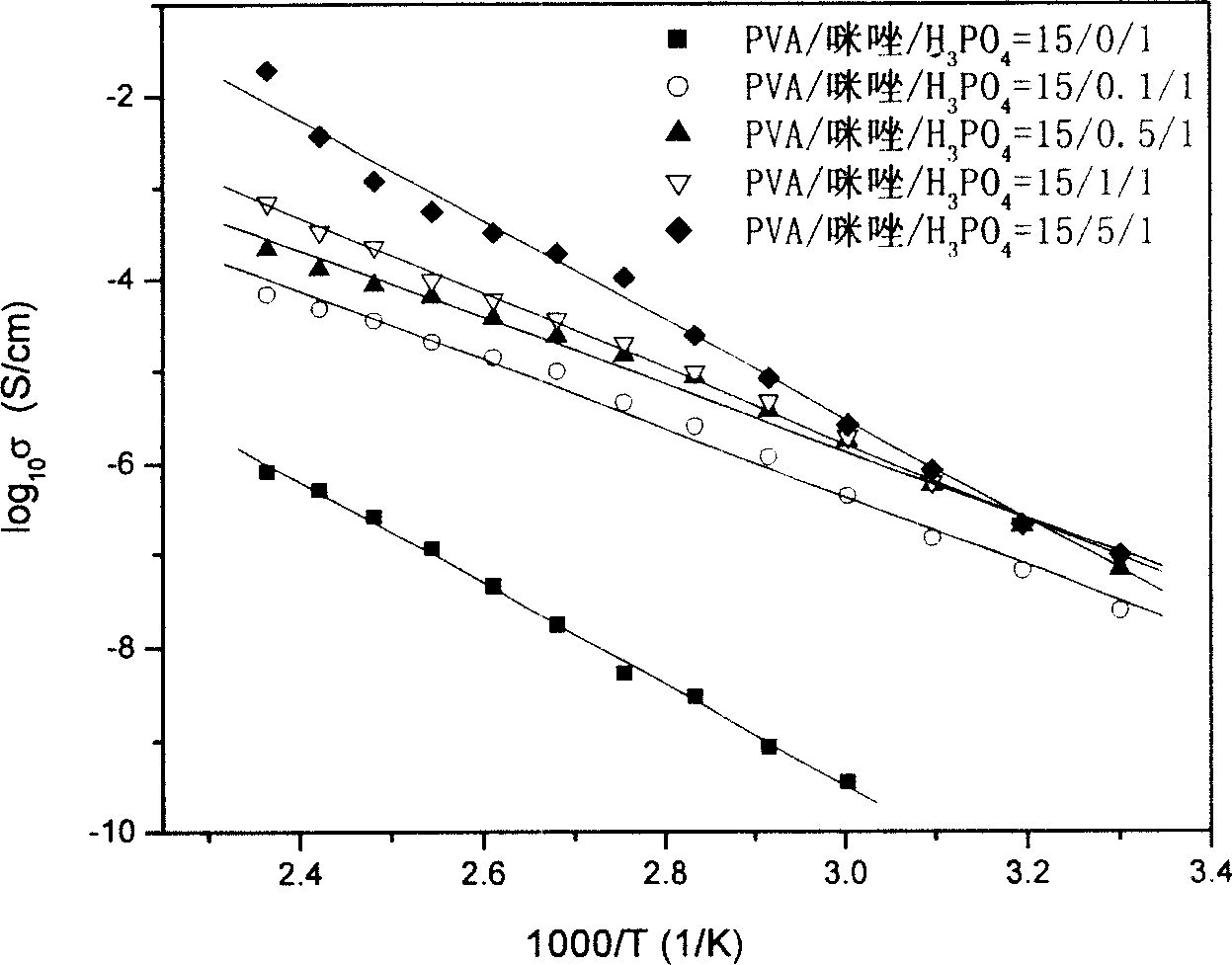

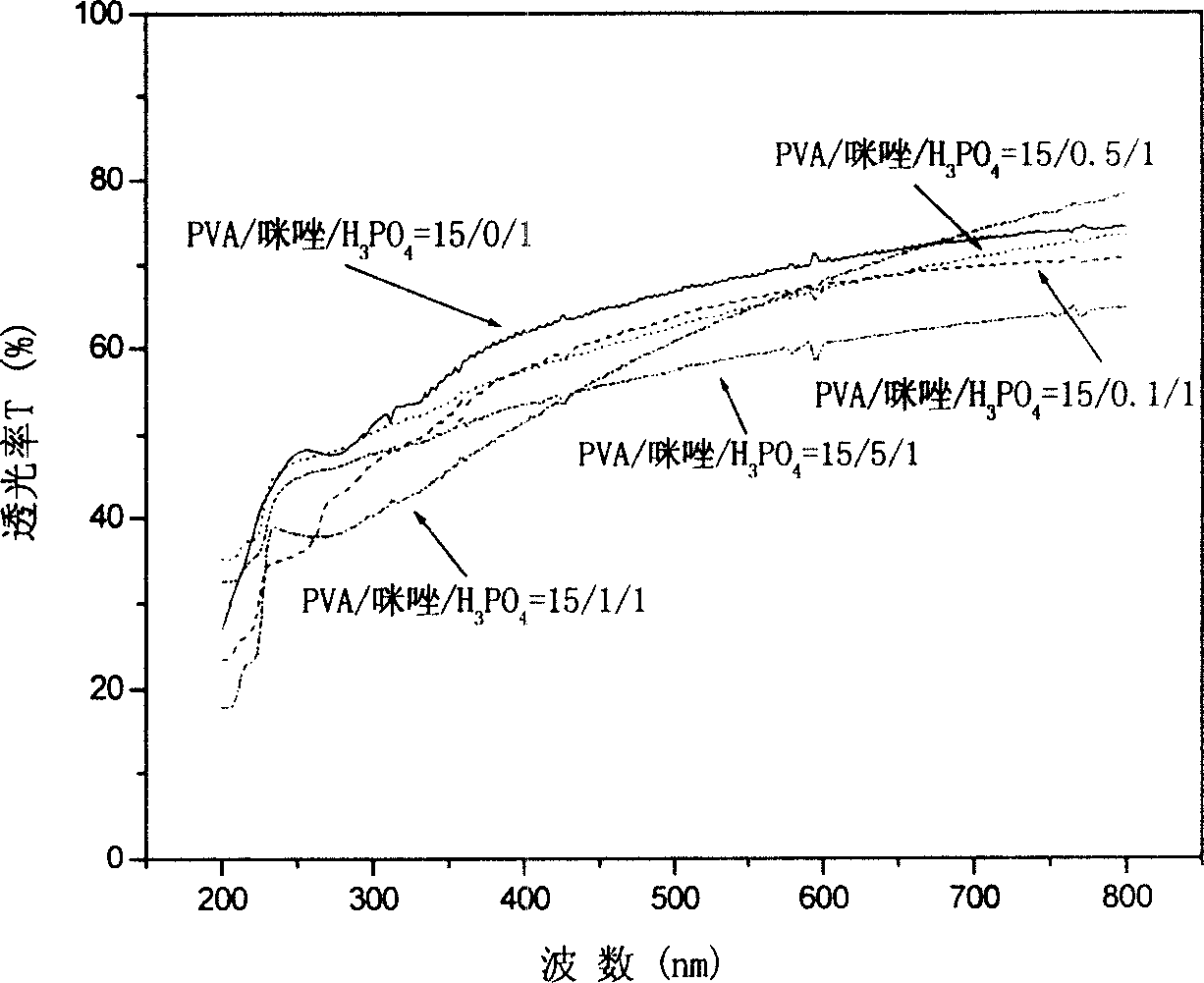

[0039] Dissolve polyvinyl alcohol and phosphoric acid in deionized water according to the above ratio, stir at a constant temperature of 100°C for 4 hours, mix evenly, and form a film on the polytetrafluoroethylene board by casting the solution, and dry it in vacuum , that is, an all-solid-state PYA / pyrazole / phosphoric acid composite proton-conducting membrane. The proton conductivity and light transmission properties of the obtained composite film are as follows: figure 1 and figure 2 shown.

Embodiment 3

[0041] The ratio of raw materials used is as follows:

[0042] 15 parts of polyvinyl alcohol (Mn=17200) (number of moles of repeating units)

[0043] 1 part of imidazole (number of moles)

[0044] Phosphoric acid 1 part (moles)

[0045] Dissolve polyvinyl alcohol, phosphoric acid and imidazole in deionized water according to the above ratio, stir at a constant temperature of 100°C for 4 hours, mix evenly, and form a film on the polytetrafluoroethylene plate by casting the solution, vacuum After drying, a fully homogeneous PVA / imidazole / phosphoric acid composite proton-conducting membrane can be obtained. The proton conductivity and light transmission properties of the obtained composite film are as follows: figure 1 and figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

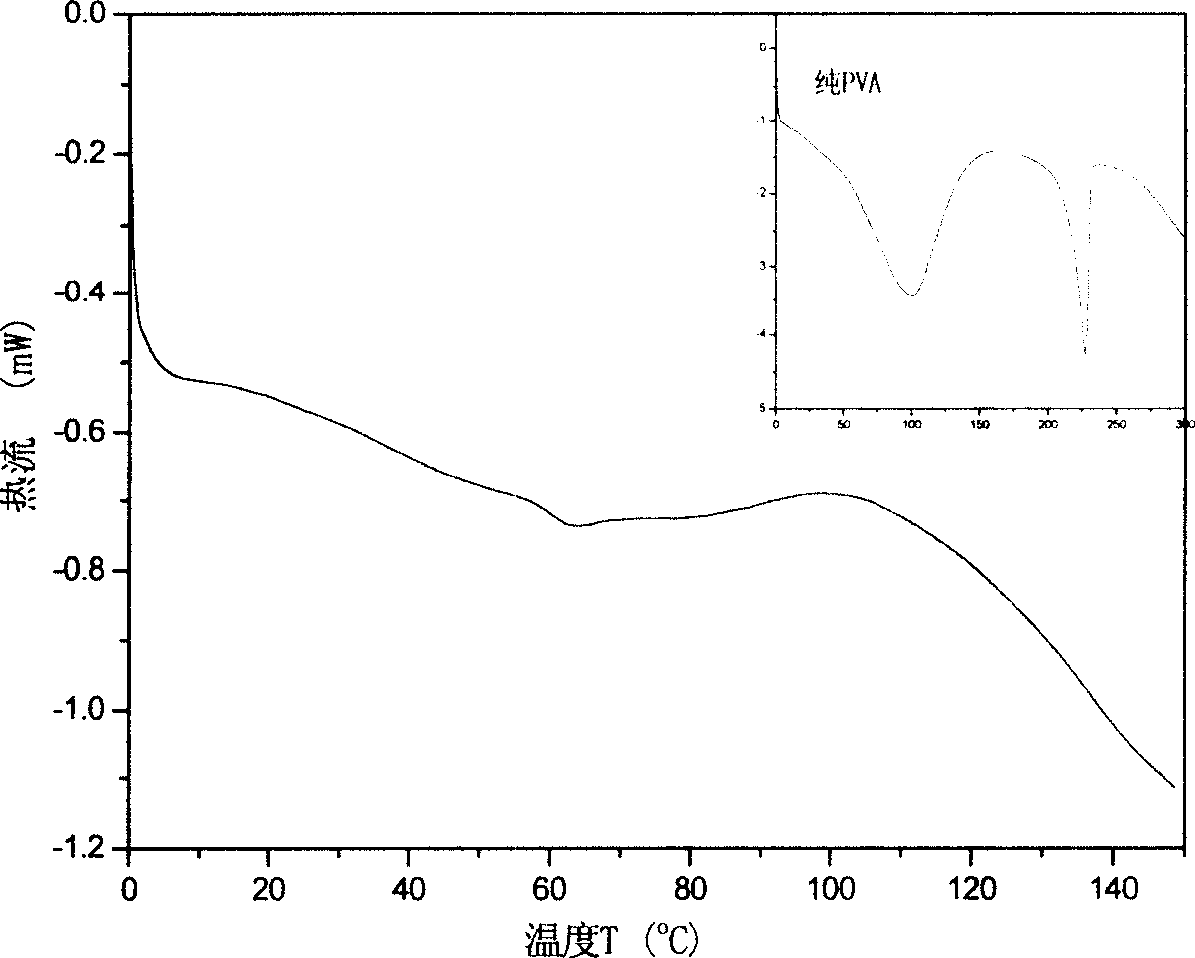

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com