Method for making white-light light-emitting diode

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of color cast and the inability to adjust various color temperatures of white light according to needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

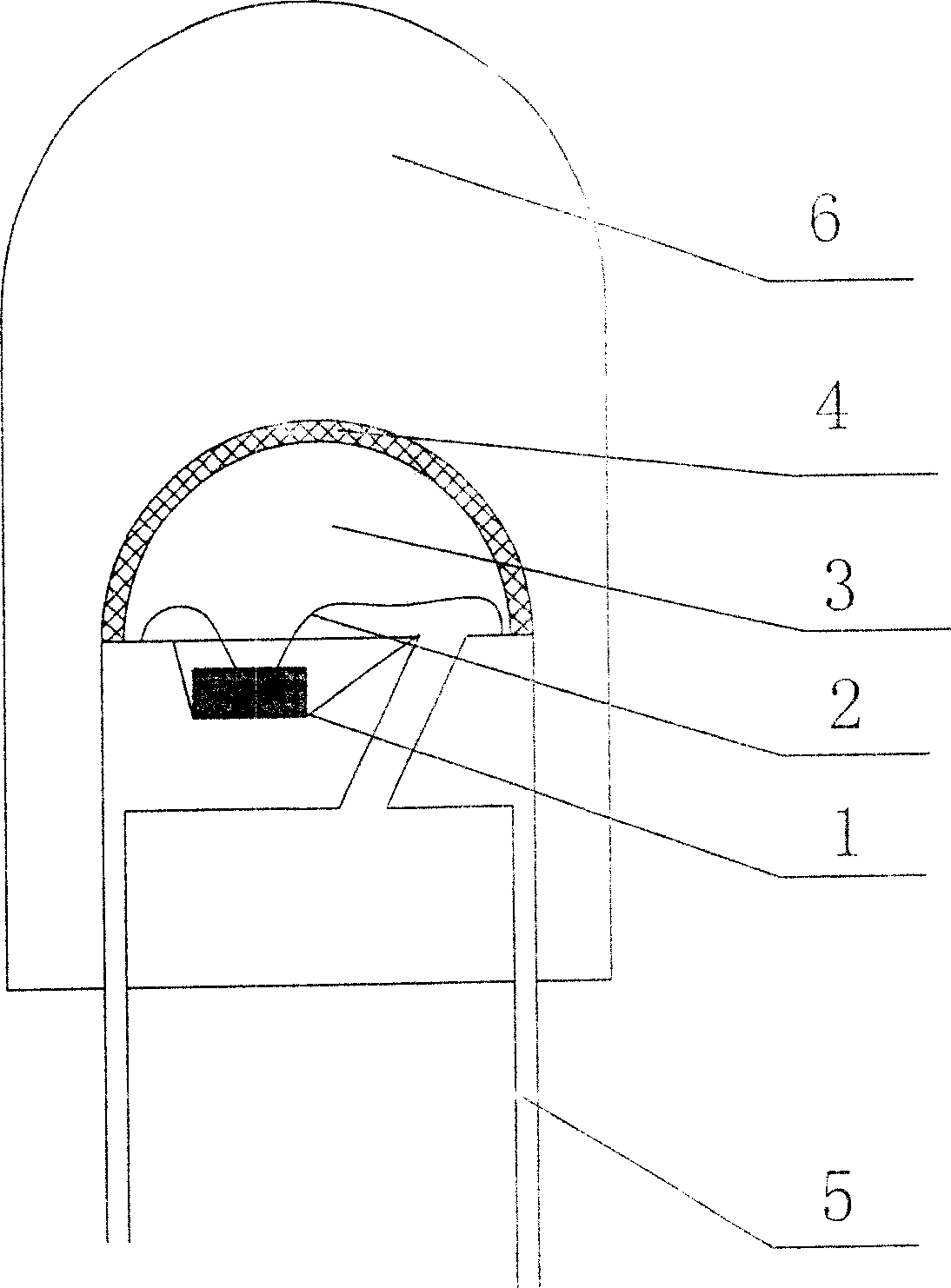

[0010] like figure 1 , use the nitride blue light diode chip 1 as the excitation light source, weld the gold wire 2 after mounting, connect with the lead wire 5, and then coat and cure the epoxy resin 3 with higher viscosity on the chip 1 and the gold wire 2 to form a ball crown shape. Mix the transparent epoxy resin, fluorescent powder and diffusion powder in a weight ratio of 0.5:0.02:0.01, coat and cure the mixture on the spherical crown-shaped epoxy resin 3 to form a fluorescent layer 4 . The epoxy resin adopts high-viscosity transparent epoxy resin, the fluorescent powder adopts fluorescent powder with an anti-attenuation of more than 50,000 hours, the light transmission of the diffusing powder should be greater than 95%, and the refractive index is 2.5. During conventional curing treatment, the curing temperature is 130° C., and the curing time is half an hour. Finally, conventional encapsulation is performed with transparent resin to form a photomask 6 .

Embodiment 2

[0012] like figure 1 , use the nitride blue light diode chip 1 as the excitation light source, weld the gold wire 2 after mounting, connect with the lead wire 5, and then coat and cure the epoxy resin 3 with higher viscosity on the chip 1 and the gold wire 2 to form a ball crown shape. Mix the transparent epoxy resin, fluorescent powder and diffusion powder in a weight ratio of 0.9:0.06:0.02, coat and cure the mixture on the spherical crown-shaped epoxy resin 3 to form a fluorescent layer 4 . The epoxy resin adopts high-viscosity transparent epoxy resin, the fluorescent powder adopts fluorescent powder with an anti-attenuation of more than 50,000 hours, the light transmission of the diffusing powder should be greater than 95%, and the refractive index is 2.5. During conventional curing treatment, the curing temperature is 130° C., and the curing time is half an hour. Finally, conventional encapsulation is performed with transparent resin to form a photomask 6 .

Embodiment 3

[0014] like figure 1 , use the nitride blue light diode chip 1 as the excitation light source, weld the gold wire 2 after mounting, connect with the lead wire 5, and then coat and cure the epoxy resin 3 with higher viscosity on the chip 1 and the gold wire 2 to form a ball crown shape. The weight ratio of the transparent epoxy resin, fluorescent powder and diffusion powder is: 1.1:0.1:0.03. Mixing is carried out, and the mixture is coated and cured on the spherical cap-shaped epoxy resin 3 to form a fluorescent layer 4 . The epoxy resin adopts high-viscosity transparent epoxy resin, the fluorescent powder adopts fluorescent powder with an anti-attenuation of more than 50,000 hours, the light transmission of the diffusing powder should be greater than 95%, and the refractive index is 2.5. During conventional curing treatment, the curing temperature is 130° C., and the curing time is half an hour. Finally, conventional encapsulation is performed with transparent resin to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com