Method and its device for extracting oil from oil containing carclazyte or oil containing diatomite

A technology for extracting oil and diatomite, which is applied in the recovery of fat oil/fatty acid from waste, production of fat, and recovery of fatty substances. It can solve the problems of waste of resources and environmental pollution, and achieve simple operation, rapid desolvation, and thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

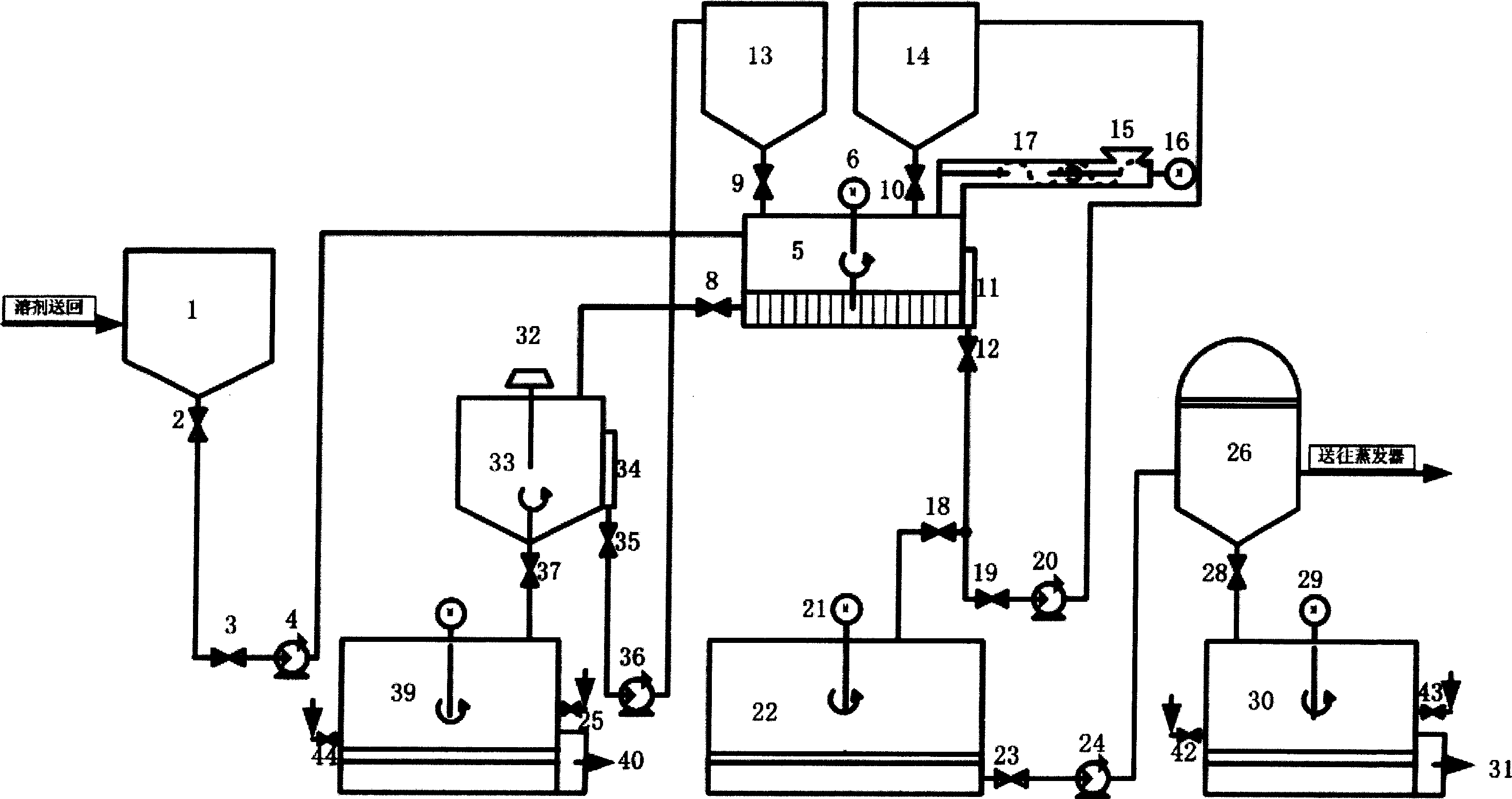

[0027] As shown in the accompanying drawing, the first extraction process to the first batch of raw materials: open valve 2, valve 3, start pump 4, the fresh solvent in the solvent tank 1 is input in the sealed band stirring leaching tank 5, the solvent weight is 7 times the weight of the oil contained in the oily clay or diatomite, after the solvent is delivered, close the valve 2, the valve 3, and the pump 4; start the motor 16, put the oily clay or diatomite into the feed port 15, and pass through the twisted Long 17 enters the sealed leaching tank 5 with agitation. After the feeding is completed, turn off the motor 16; start the motor 6 for the first stirring extraction, and after stirring for 10 to 15 minutes, turn off the motor 6 for natural precipitation; settling for 40 to 60 minutes Afterwards, open the solid-liquid separation valve 11, valve 12, valve 18, input the concentrated mixed solution into the temporary storage tank 22 of the concentrated mixed solution with s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap