Fuel jet valve for internal combustion engine

A fuel injection and internal combustion engine technology, applied in fuel injection devices, mechanical equipment, engine components, etc., can solve problems such as the limitation of degrees of freedom, and achieve the effects of elimination of limitations, stable operation, and suppression of pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

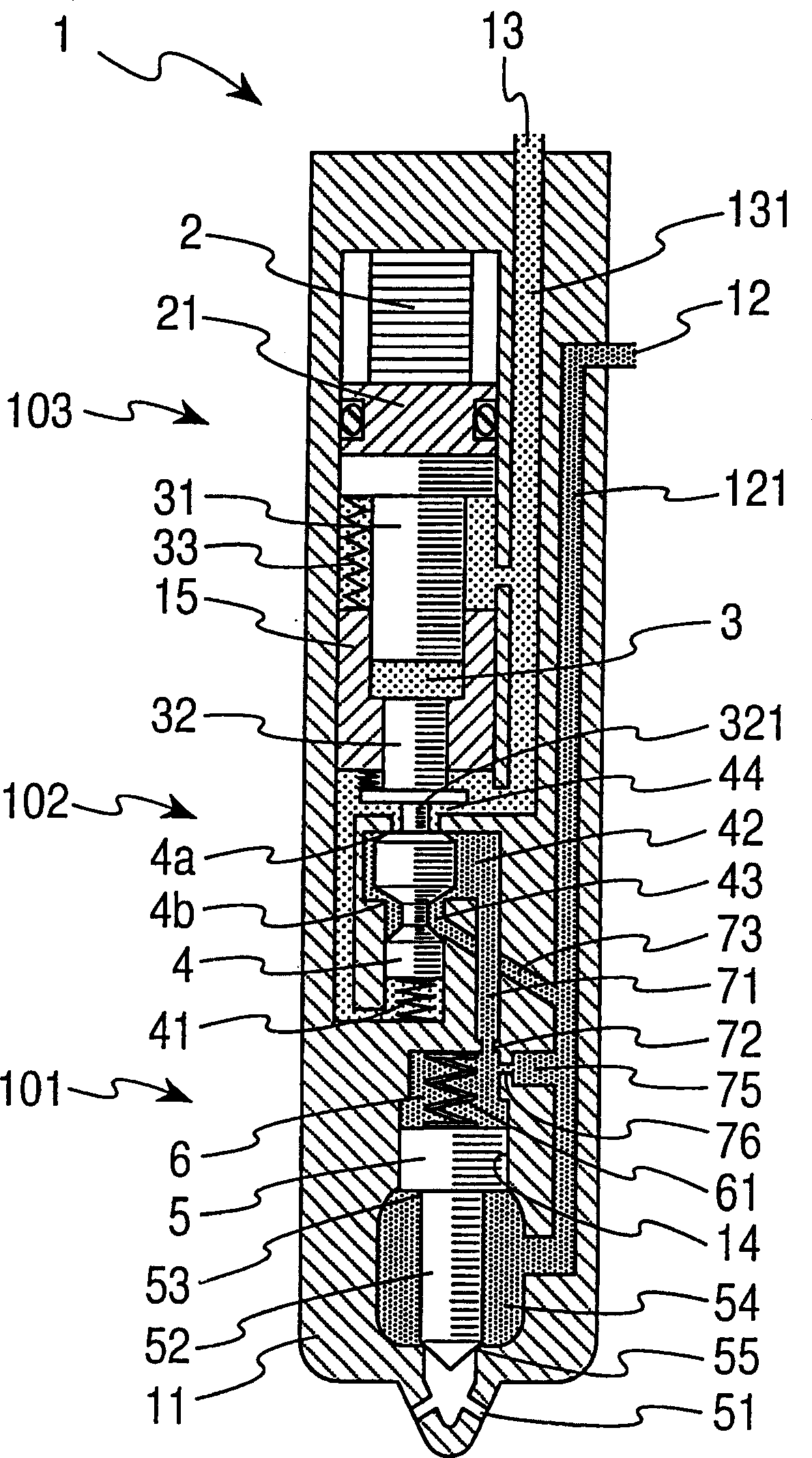

[0014] see figure 1 , which shows a fuel injection valve 1 according to an exemplary embodiment of the invention. The fuel injection valve 1 of this embodiment is used in a common rail fuel injection system of a diesel engine. A plurality of fuel injection valves 1 are placed according to corresponding cylinders of the diesel engine, and receive fuel from a common rail common to the plurality of fuel injection valves. The high-pressure fuel supply pump supplies the fuel from the fuel tank to the common rail, and the common rail converges the fuel to a predetermined high pressure (for example, 20 to 200 Pa) consistent with the fuel injection pressure.

[0015] The lower end portion of the fuel injection valve 1 has a nozzle portion 101 including a nozzle needle 5 . The fuel injection valve 1 is installed such that the nozzle portion 101 protrudes into a combustion chamber. The fuel injection valve 1 has a hydraulic control unit 102 (hydraulic control valve) in the middle. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com