Multi roller mill for eliminating belt mill trace

A rolling mill, plate and strip technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of destroying the surface quality of the product, the shape of the bus bar, etc., to ensure the surface quality and increase the manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

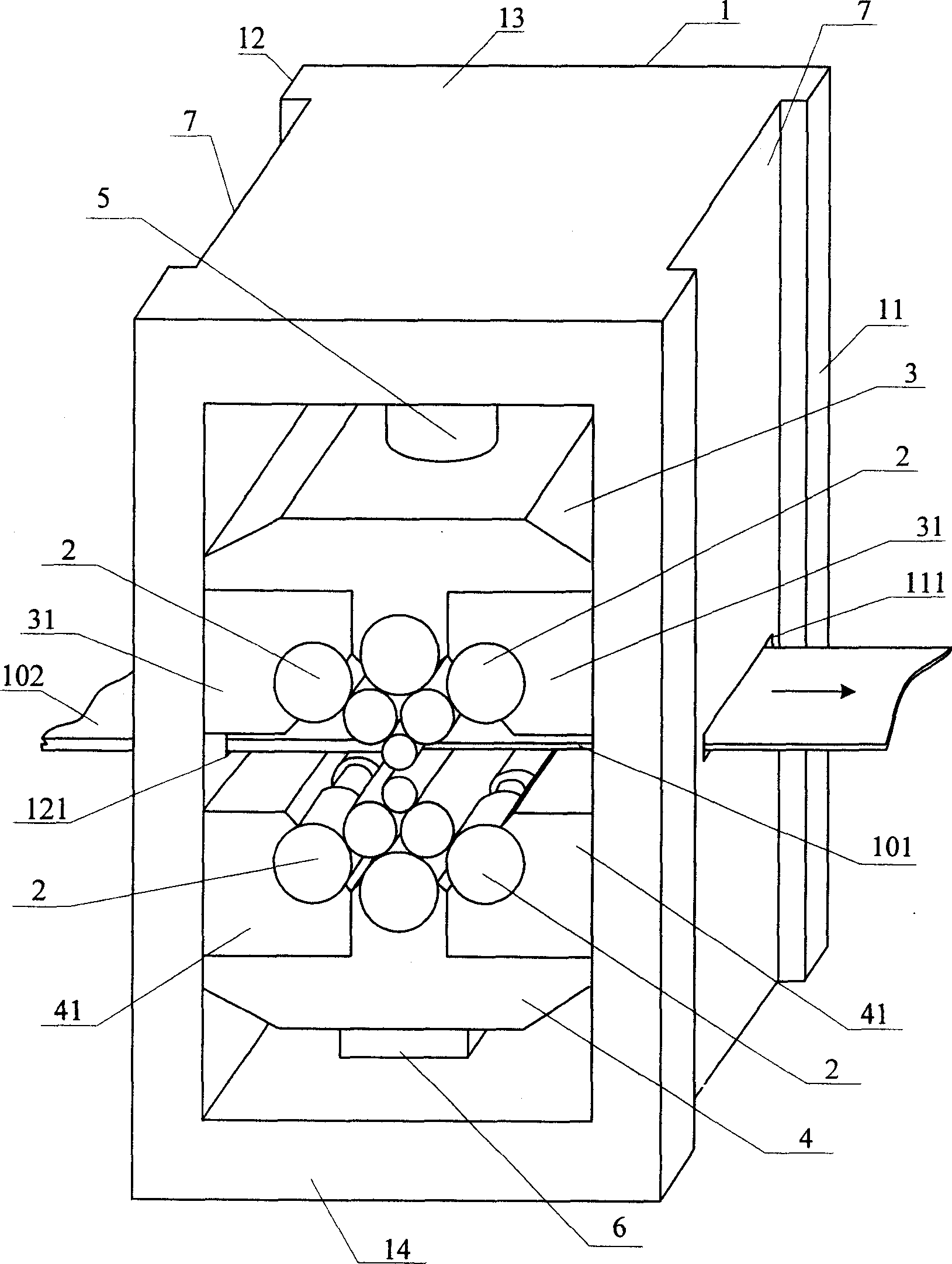

[0018] figure 1 Shown is a three-dimensional schematic diagram of the first specific embodiment of the present invention, which includes a frame 1 and a symmetrical upper tower roller system that is respectively arranged on the upper and lower sides of the rolled piece 101 in the frame 1 And lower tower-shaped roller system, frame 1 is a tunnel-shaped frame integral body along the tower-shaped roller system axial direction formed by panel 11, back plate 12, top plate 13 and base plate 14 enclosing. The surface of the back plate is provided with a feed opening 121 for the strip blank 102 to enter. The surface of the panel 11 is provided with a discharge port 111 for outputting the rolled piece 101 . Top-to-bottom grooves 7 are respectively opened on the outer surfaces of the panel and the backboard. The opening of the grooves 7 can not only greatly save the manufacturing material cost of the frame 1, but also help to improve the rigidity of the frame in the horizontal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com