Production technology of grease cooler air chamber and its product

A technology of oil cooler and production process, applied in machine/engine, engine lubrication, mechanical equipment, etc., can solve the problems of residual pores, high production cost, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

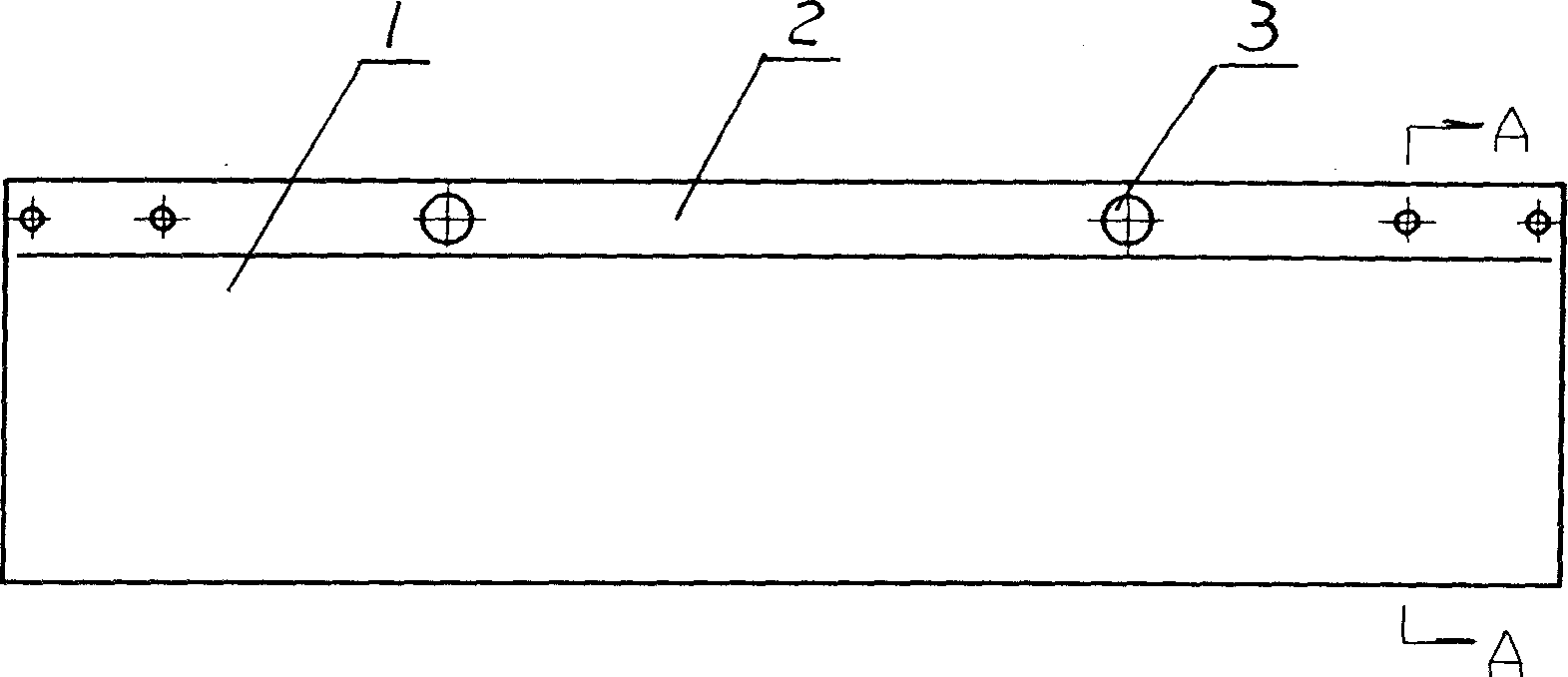

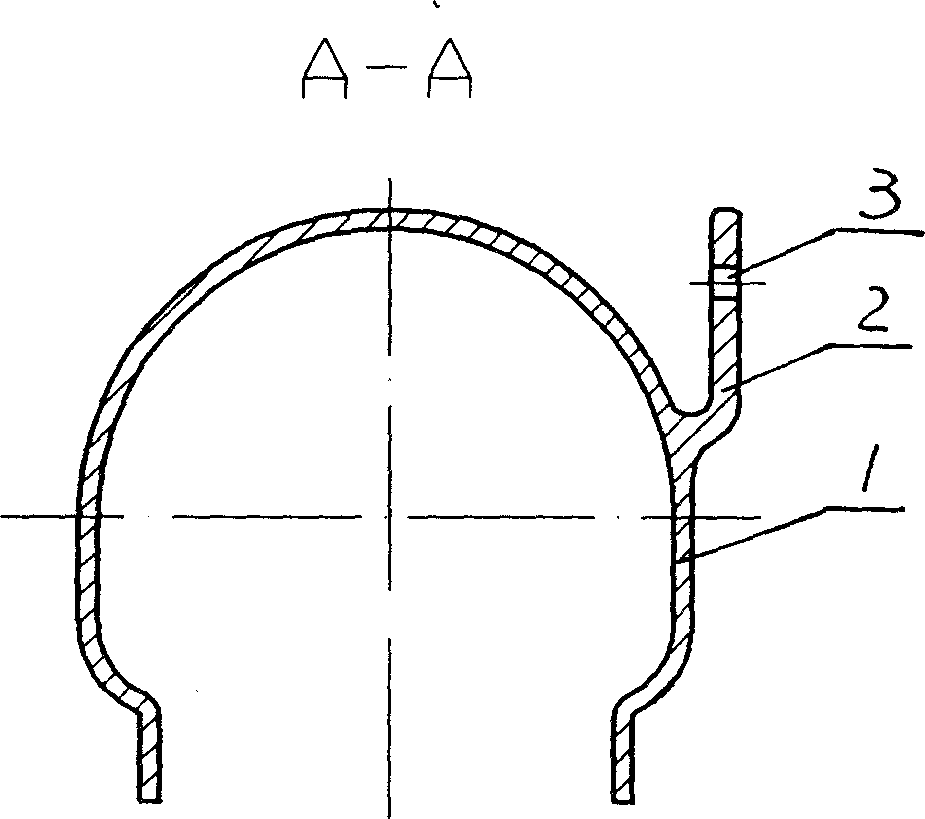

[0008] Embodiment 1 of the present invention, with reference to the accompanying drawings, the production process of the oil cooler air chamber cavity is as follows: step 1, the aluminum rod of 100 is hot-extruded by an aluminum profile extrusion machine to produce an aluminum profile with a certain specification and cross-sectional size , the aluminum rod material is 3A21, the heating temperature is 500°C-530°C, the length of the aluminum rod is 380±5mm, the extrusion temperature is 440°C-480°C, and then the profile is cut to the required length; Step 2 , according to the drawing size of the aluminum profile, use a milling machine to mill the sawn aluminum profile; step 3, use a 100T punch press, and punch the profile with a punching die.

[0009] Embodiment 2 of the present invention, with reference to the accompanying drawings, the product produced by the production process of the oil cooler air chamber cavity is that the air chamber cavity is composed of a cavity body 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com