Polyester-modified polysiloxanes and their use as additives for thermoplastics, moulding compounds and coating materials

A thermoplastic, polyester modification technology, used in coatings, textiles and paper, one-component synthetic polymer rayon, etc., can solve problems such as insufficient scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

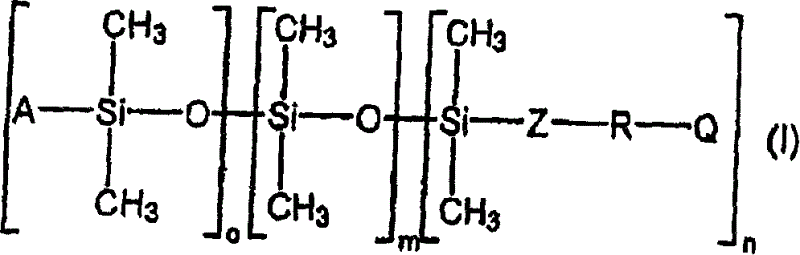

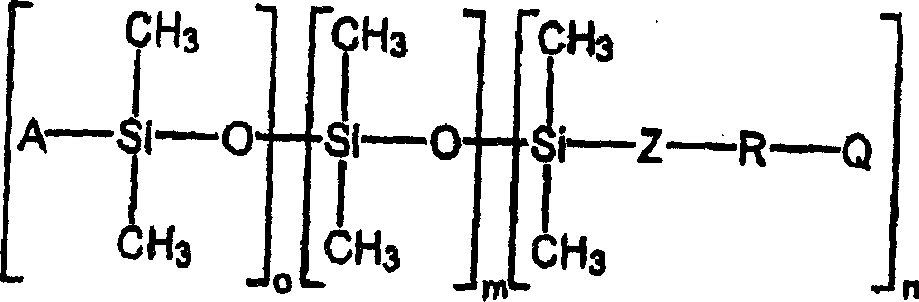

[0047] In a reaction vessel with a stirrer and a reflux condenser, make 406.8g (0.25mol) of polysiloxane having the following average formula

[0048]

[0049] This was mixed with 742.0 g (6.5 mol) of ε-caprolactone, and after addition of 100 ppm of dibutyltin dilaurate, the mixture was heated to 180° C. under nitrogen. After a reaction time of 6 hours, the reaction mixture was cooled to 80°C and 460.0 g of Shellsol A were added. Subsequently 73.9 g (0.25 mol) of stearyl isocyanate were added, and the mixture was stirred at 80° C. for a further 30 minutes. The solvent was removed from the reaction mixture by evacuation (40 mbar) and warming to 160°C. The product obtained was a waxy solid with a melting point of 53°C.

Embodiment 2

[0050] Embodiment 2 (not the present invention):

[0051] In a reaction vessel with a stirrer and a reflux condenser, make 507.5 g (0.25 mol) of polysiloxane having the following average formula

[0052]

[0053] This was mixed with 742.0 g (6.5 mol) of ε-caprolactone, and after addition of 100 ppm of dibutyltin dilaurate, the mixture was heated to 180° C. under nitrogen. After a reaction time of 6 hours, the reaction mixture was cooled to 80° C. and 460.0 g of She11sol A were added. Subsequently 147.8 g (0.5 mol) of stearyl isocyanate were added, and the mixture was stirred at 80° C. for a further 30 minutes. The solvent was removed from the reaction mixture by evacuation (40 mbar) and warming to 160°C. The product obtained was a waxy solid melting at 51°C.

[0054] Use case:

[0055] 0.05 g of the product from Example 1 were dissolved in 100 g of a 10% polymethylmethacrylate / ethyl acetate solution. In size 100 x 250mm 2 A 200 μm thick film was produced on a glass pl...

Embodiment 3

[0059] In a reaction vessel with a reflux condenser, 507 g (0.5 mol) of unsaturated polyester having the average formula

[0060]

[0061] and 1798g (0.45mol) of polysiloxanes having the following average formula

[0062]

[0063] and 988 g of xylene were mixed under a nitrogen atmosphere, and the mixture was heated to 100°C. Then 1.4 g of a 6% hexachloroplatinic acid / 2-propanol solution were added. After a reaction time of 3 hours, the solvent was stripped off under vacuum (40 mbar, 180° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com