Ultrafast cooling device for wire and rod hot rolling production line

An ultra-fast cooling and production line technology, which is applied in the field of cooling devices for continuous processing of strips or wires, can solve the problems that the cooling device cannot be satisfied and cannot be implemented in the manufacturer, achieves huge social and economic benefits, and is convenient for maintenance. , the effect of short cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

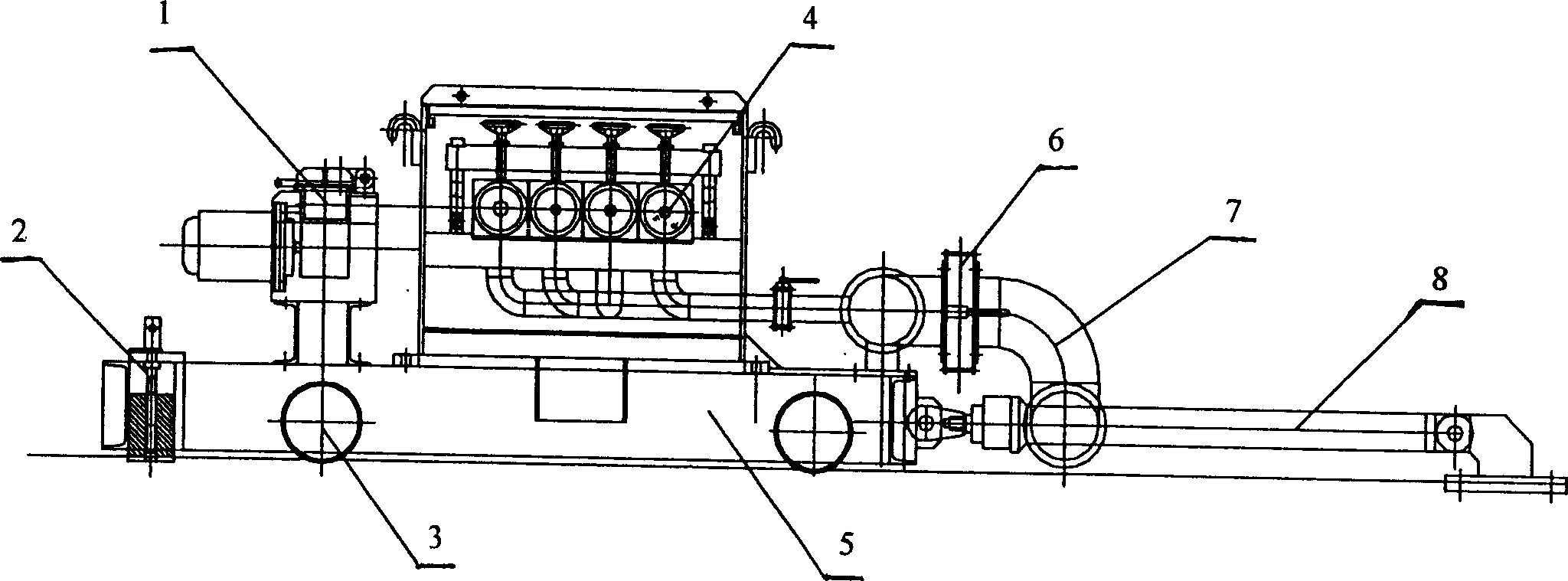

[0031] Example 1: HRB335 ribbed steel bar of Φ12mm produced by three-wire split rolling

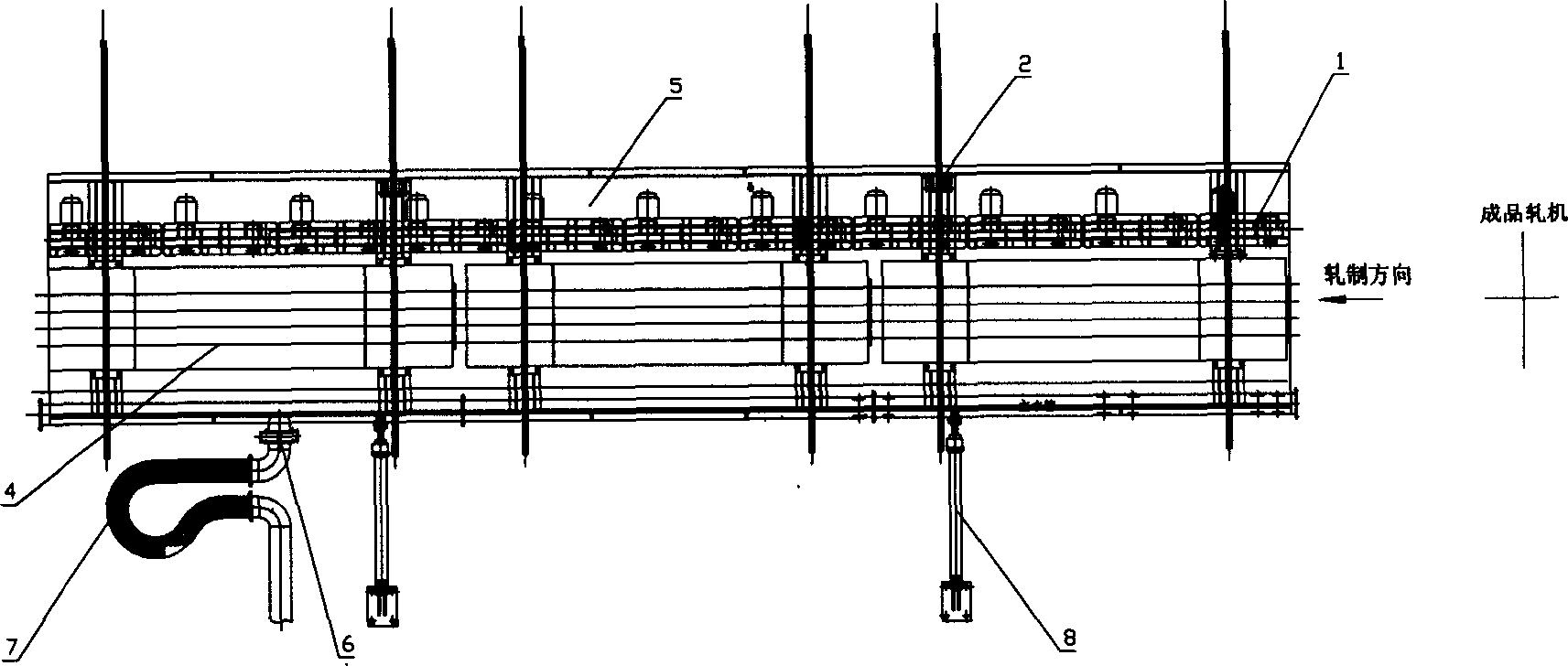

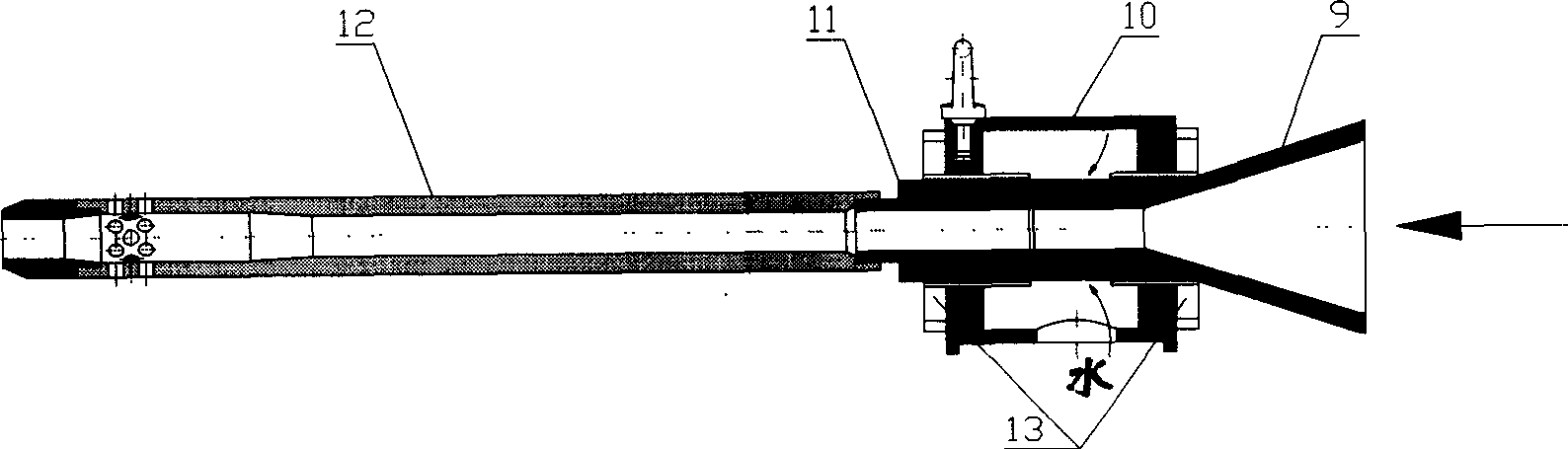

[0032]According to the heat treatment process requirements of steel bars, the entire cooling device is determined to be composed of three sets of parallel cooler boxes, and three forward coolers and one reverse sprinkler are arranged in series in the box. The inner diameter of the cooler and the sprinkler is Φ36mm, and the length of each cooler is 1.2 meters; the length of the sprinkler is 0.4 meters; the distance between the two boxes is 0.2 meters, and the length of the entire cooler device is about 12.8 meters. The water supply system of each cooler and water catcher in the cooling device is controlled by high-pressure water valves that are individually opened and closed, and they can be adjusted and opened and closed individually according to process requirements.

[0033] Trial production of Φ12mm HRB335 ribbed steel bars with the ultra-rapid cooling device of the present invention i...

Embodiment 2

[0037] Embodiment 2 adopts the ribbed steel bar of the RHB400 of Φ 25mm to be produced by single wire rolling

[0038] According to the technical requirements of the heat treatment of the above-mentioned steel bars, a cooling device consisting of a group of cooler boxes is adopted, which is divided into four sections, and each section is composed of two coolers and a reverse water splasher connected in series. The inner diameter of the cooler and the splasher is Φ48mm. Each cooler is 1.2m long, the sprinkler is 0.4m long, the distance between the two boxes is 0.2m, and the overall length is about 12.8m. Each cooler and reverse sprinkler can be opened and closed independently and the water pressure can be adjusted.

[0039] When producing Φ25mm HRB400 ribbed steel bars, 14 full continuous rolling mills are used, including 6 rough rolling mills, 6 intermediate rolling mills, and 2 finishing mills. Each mill rolls 1 pass, and the billet is 150mm billet The material is 20MnSi st...

Embodiment 3

[0043] Example 3 The HRB500 ribbed steel bar of Φ16mm is produced by double-strand rolling

[0044] According to the requirements of the above steel heat treatment process, combined with the actual situation of the production workshop, the entire cooling device is determined to be composed of two sets of parallel cooler boxes, and each set of cooler boxes is composed of three sections. In the first section, three coolers and a water thrower are connected in series in sequence; in the second and third sections, two coolers are connected in series in forward direction and a reverse water thrower is connected in series. The inner diameter of the cooler and the sprinkler is Φ36mm, the length of each cooler is 1 meter, the length of the sprinkler is 0.4 meters, the distance between the two boxes is 0.4 meters, and the total length is about 9.5 meters. Each cooler and sprinkler can be opened and closed independently, and the pressure of its water flow or air flow can also be adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com