A planar inductive component and an integrated circuit comprising a planar inductive component

A planar inductor and component technology, applied in electrical components, transformer/inductor components, circuits, etc., can solve problems such as low quality factor, achieve high quality factor, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

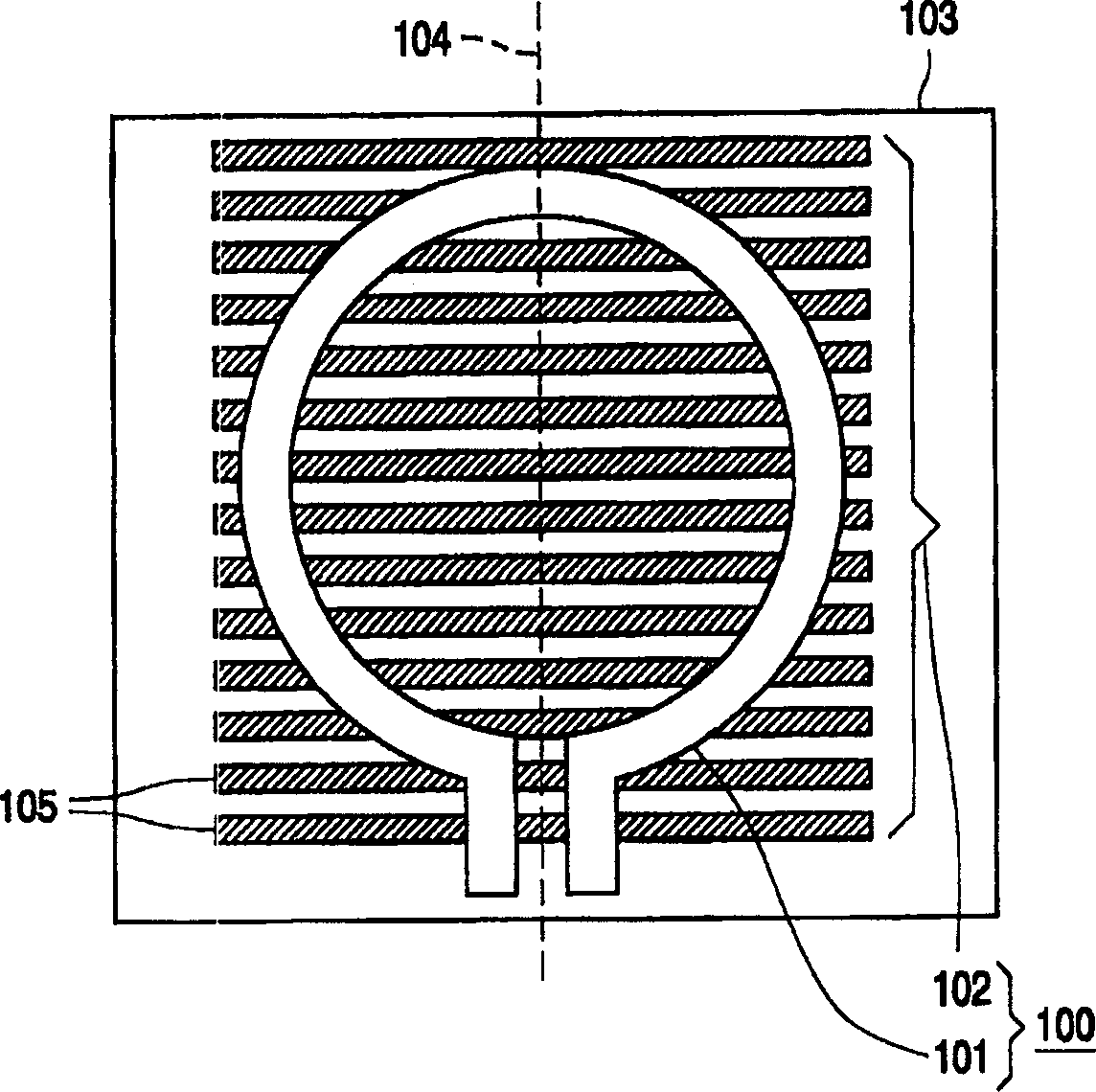

[0033] figure 1 A top view of an embodiment of a planar inductive element according to the invention is shown. The illustrated planar inductive element 100 includes a coil 101 and a patterned ground shield 102 . The planar inductive element 100 is located on top of another layer, the substrate 103 . The coil 101 is essentially a track of conductive material, such as aluminium, that forms a generally circular ring. The trajectory is symmetrical about a mirror plane 104 whose direction is perpendicular to the surface of the substrate 103 . A patterned ground wire shield is located between the coil 101 and the substrate 103 . The ground shield 102 includes a plurality of traces 105 formed from a conductive material, such as aluminum or polysilicon. The trace 105 lies in a plane parallel to the surface of the substrate, and the direction of the trace 105 is perpendicular to the mirror plane 104 .

[0034] At the terminals of the planar inductive element 100, the voltage diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com