Method of producing aluminium titanium alloy using aluminium electrolytic tank

An aluminum electrolytic cell and aluminum-titanium alloy technology, which is applied in the field of aluminum-titanium alloy production with aluminum electrolytic cells, can solve the problems of low anode compressive strength, large anode resistance and high energy consumption, and achieve no segregation of chemical composition and uniform chemical composition. , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

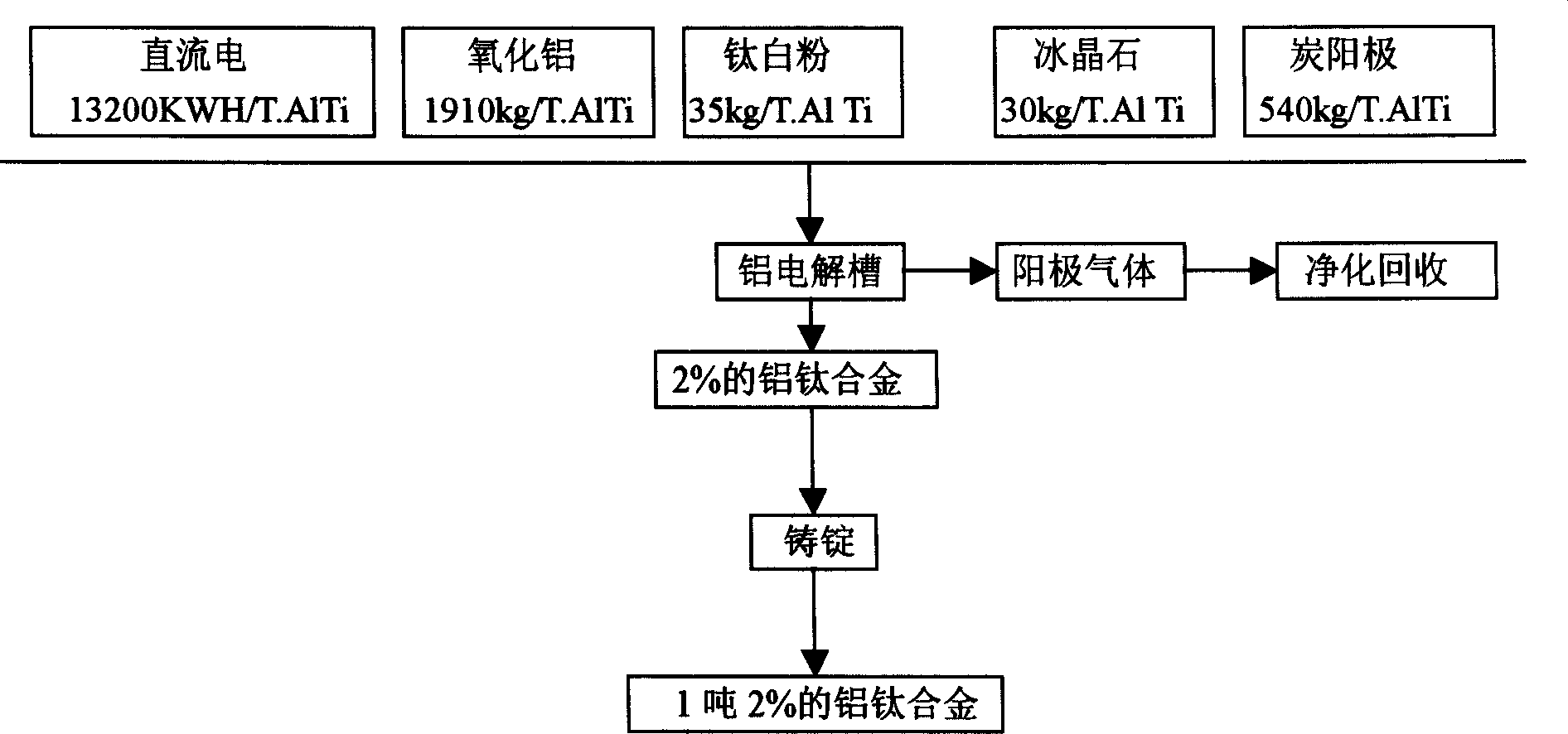

[0013] Referring to the accompanying drawings, an aluminum electrolysis plant with an annual output of 36,500 tons has 100 aluminum electrolysis cells of 135KA. The plant plans to produce 3,650 tons of aluminum-titanium alloys with a titanium content of 2% per year, and 10 aluminum electrolytic cells can be selected for aluminum-titanium alloy production. The technical conditions of the selected 10 electrolytic cells are as follows: cell operating voltage 4.1-4.3V, electrolysis temperature 930-960°C, molten salt level 17-20cm, aluminum liquid level 18-24cm, molecular ratio 2.4-2.8. Add 35kg of titanium dioxide with a purity of 98% and 1910kg of alumina with a purity of 98% to each aluminum electrolytic cell every day, and each cell can produce 1 ton of aluminum-titanium alloy with a titanium content of 2% every day. The yield rate is above 98%. The aluminum-titanium alloy melt produced in the tank is sucked out by the aluminum suction bag every day, and transported to the cast...

Embodiment 2

[0015] An aluminum electrolysis plant with an annual output of 100,000 tons has 120 300KA aluminum electrolysis cells. The plant plans to produce 4,140 tons of aluminum-titanium alloy with a titanium content of 2.5% per year, and 5 aluminum electrolytic cells can be selected for aluminum-titanium alloy production. The technical conditions of the 5 selected electrolytic cells are as follows: cell operating voltage 4.1V-4.3V, electrolysis temperature 930°C-960°C, molten salt level 17-20cm, aluminum liquid level 18-24cm, molecular ratio 2.4-2.8. Add 95kg of titanium dioxide with a purity of 98% and 4380kg of alumina with a purity of 98.4% to each aluminum electrolytic cell every day, and each cell can produce 2270kg of aluminum-titanium alloy with a titanium content of 2.5% every day, and the actual harvest of titanium The rate is above 98%. The aluminum-titanium alloy melt produced in the tank is sucked out with the aluminum suction bag every day, and transported to the foundry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com