Straw slices purifying machine

A technology for straw flakes and miscellaneous machines is applied in the field of machinery for removing heavy impurities, which can solve the problems of difficult removal, reduced papermaking quality, damage, etc., and achieves the effects of simple structure, improved purity, and no waste of water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

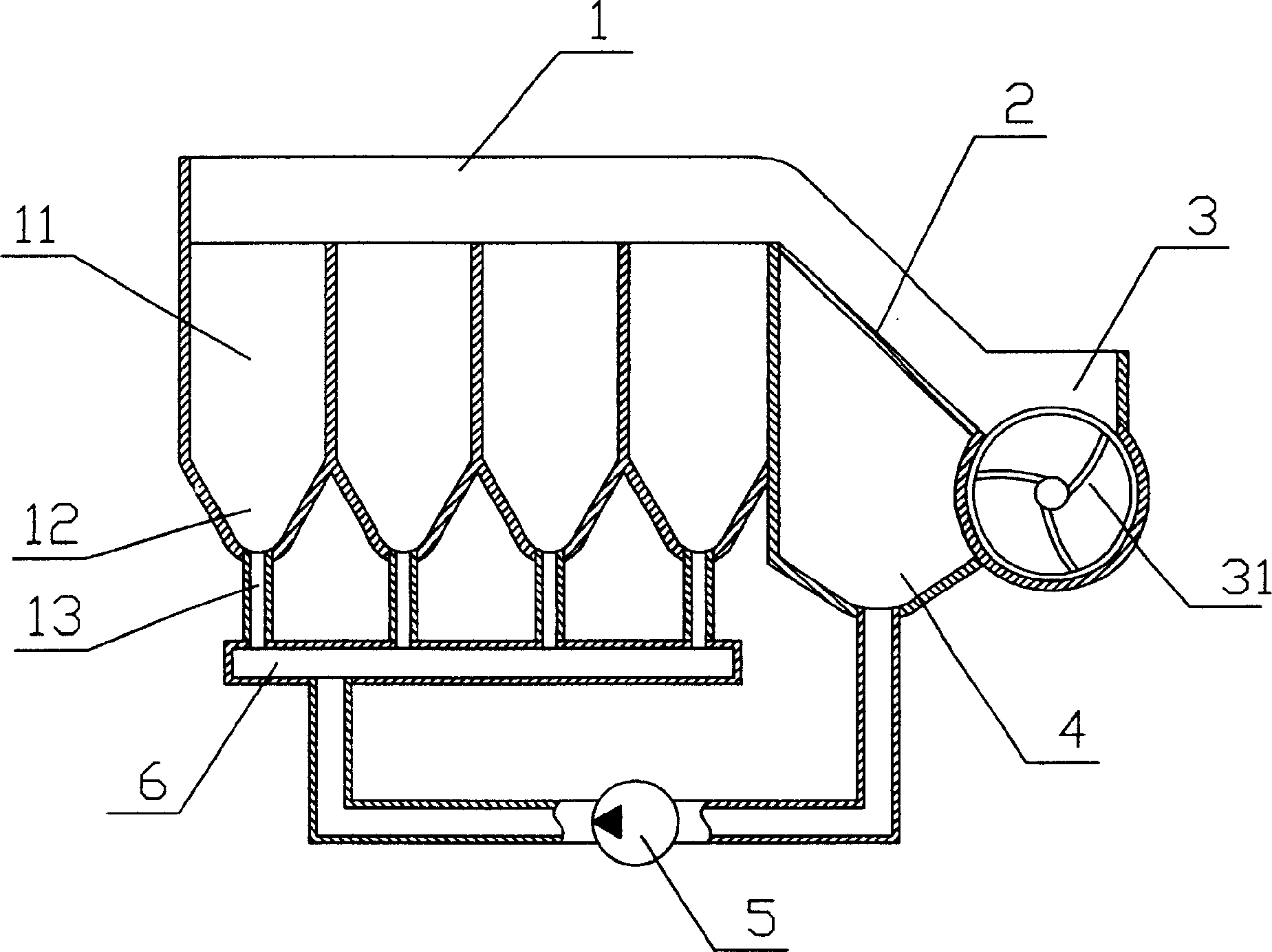

[0017] Embodiment one: if figure 1 As shown, a kind of grass chip remover includes a tank body 1 filled with water inside, a separation device 2 that separates water and grass chips at the rear of the tank body 1, and a water collection device 4 located below the separation device 2. The collection device 3 for collecting the grass pieces separated by the separation device 2, the water collection device 4 and the tank body 1 are connected by a pipeline 6, and the water collection device 4 is provided on the pipeline to transport the water in the water collection device 4 to The circulating water pump 5 in the tank body 1; the present embodiment utilizes the principle of buoyancy to suspend the grass slices on the surface of the water, while the heavy impurities sink to the bottom of the water. The grass flakes are brought into the separation device, and the grass flakes after removing impurities go to the next process, and the outflowing water flows back to the flotation tank ...

Embodiment 2

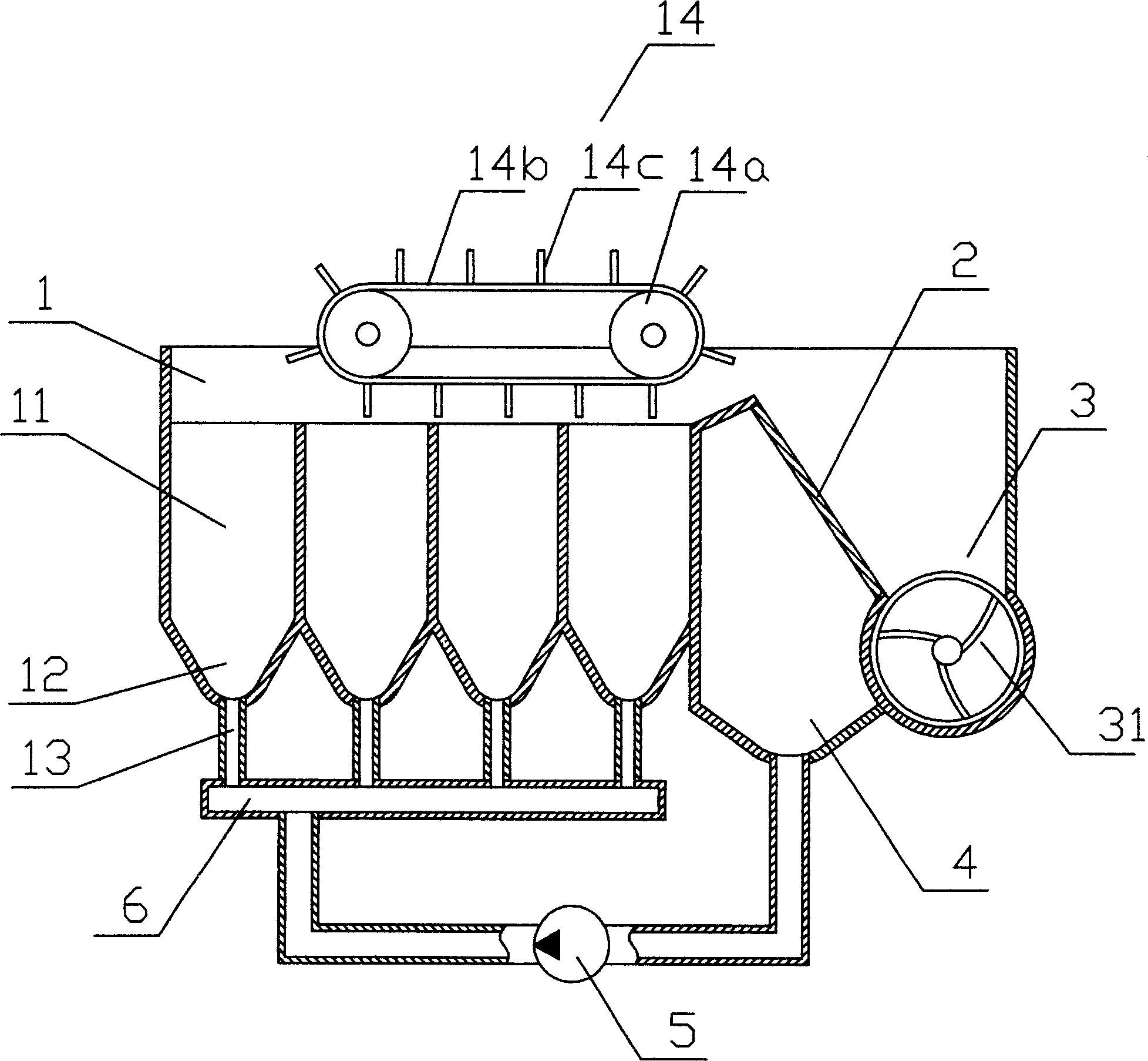

[0021] Embodiment two: if figure 2 As shown, the technical solution of this embodiment is basically the same as that of Embodiment 1, except that a feeding device 14 that promotes the movement of forage to the separation device 2 is added above the tank body 1 filled with water. The material shifting device 14 includes a power unit (not shown in the figure), two pulleys 14a, a belt 14b installed on the two pulleys 14a, and a material shifting claw 14c is installed on the belt 14b. The power unit preferably adopts an electric motor.

[0022] Certainly, the described material shifting device 14 can also adopt a power device, two sprockets 14a, a chain 14b installed on the two sprockets 14a, and a material shifting claw 14c is installed on the described chain 14b.

Embodiment 3

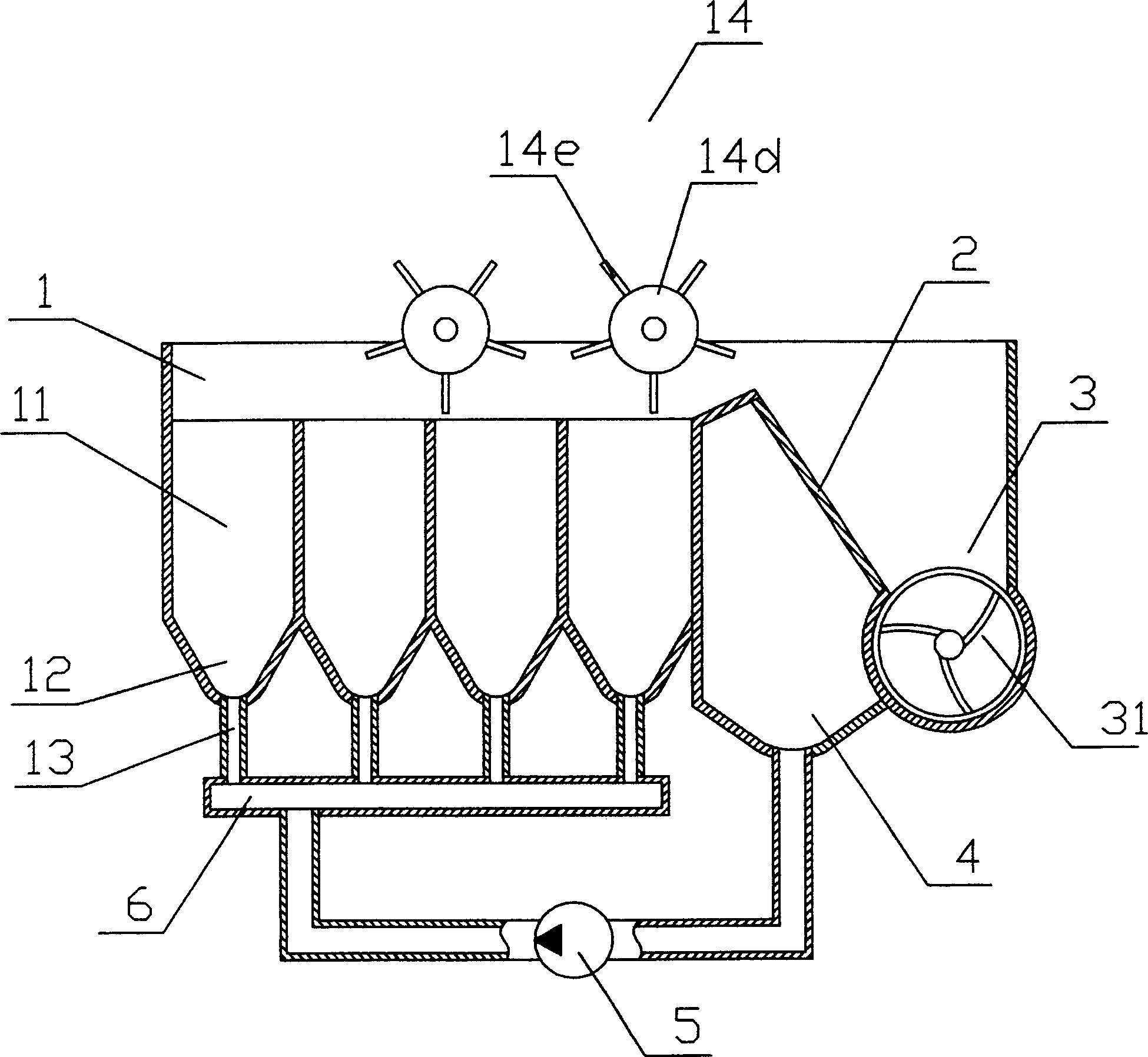

[0023] Embodiment three: as image 3 As shown, the technical solution of the present embodiment is basically the same as that of the second embodiment, the difference is that the shifting device 14 includes a power device and a shifting wheel 14d, and the shifting claw 14e is installed on the shifting wheel 14d . There can be multiple setting devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com