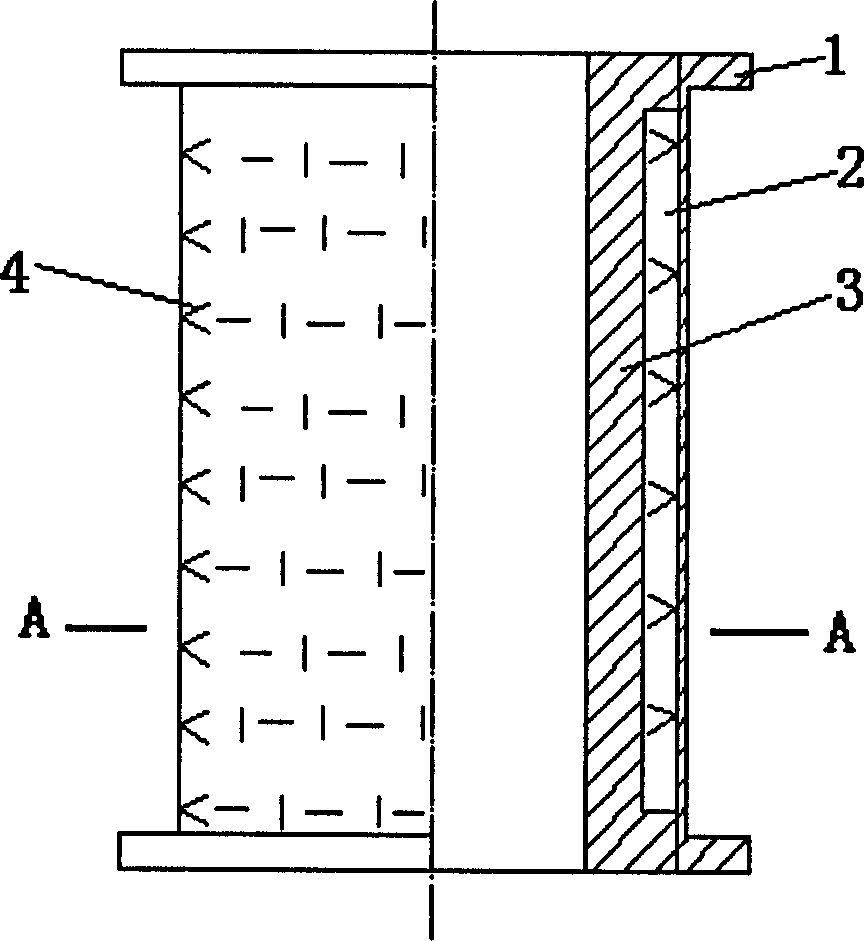

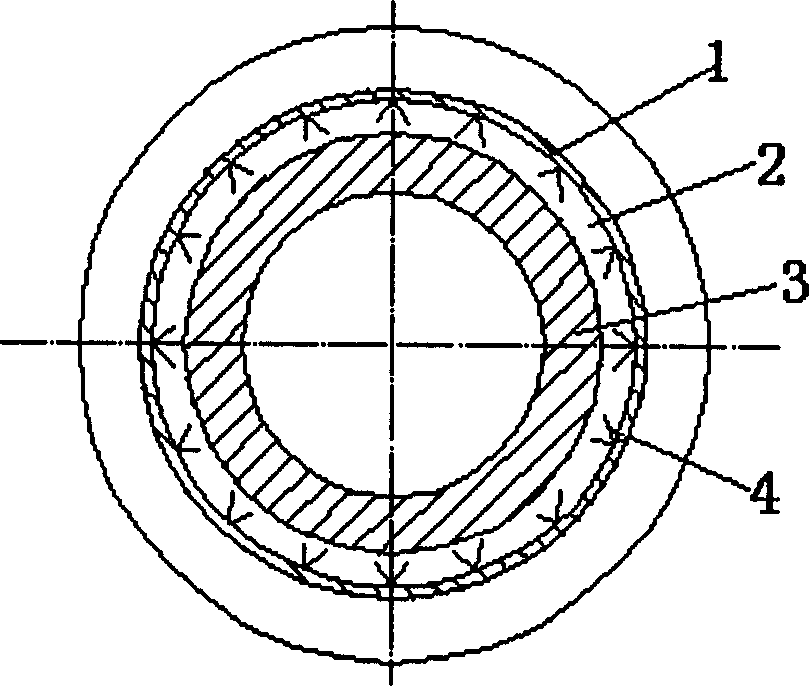

Double layer fireproof linings branch blast tube of blast furnace

A technology of refractory lining and blast furnace, which is applied in the fields of refractory materials for blast furnaces and blast furnace process equipment. It can solve the problem that refractory fibers cannot ensure that the steel shell does not turn red for a long time, ring and strip cracks are prone to appear, and the stability of refractory lining is poor, etc. problems, to achieve good volume stability, less redness, and improve rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0022] The heat insulation layer material is QCI-135H lightweight castable, the thickness of the heat insulation layer is 35mm, the working lining material is QCA-18S corundum castable with steel fiber, the working lining thickness is 80mm, and the height of the heat insulation layer is low 20mm at the end of the steel shell, the anchor nails are V-shaped, the diameter of the anchor nails is 4mm, the material of the anchor nails is Q235-A, the height of the anchor nails is 12mm, and the distribution interval of the anchor nails is 100mm. With the same 3200m 3 Compared with blast furnace air supply branch pipes, the surface temperature of the first air supply branch pipe in the prior art is between 360-400°C, and the surface temperature is between 260-300°C by the present invention, with an average reduction of about 100°C. According to the surface area: 248.69m 2 1. The way of heat dissipation is natural convection, and the ambient temperature is 20°C; the heat dissipation pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com