Method and equipment for manufacturing composite plate

A composite board and equipment technology, applied in the field of composite board manufacturing, can solve the problems of heavy hydraulic press, inconvenient advancement and launch, low work efficiency, etc., and achieve the effects of reducing equipment cost, realizing assembly line production, and expanding production scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

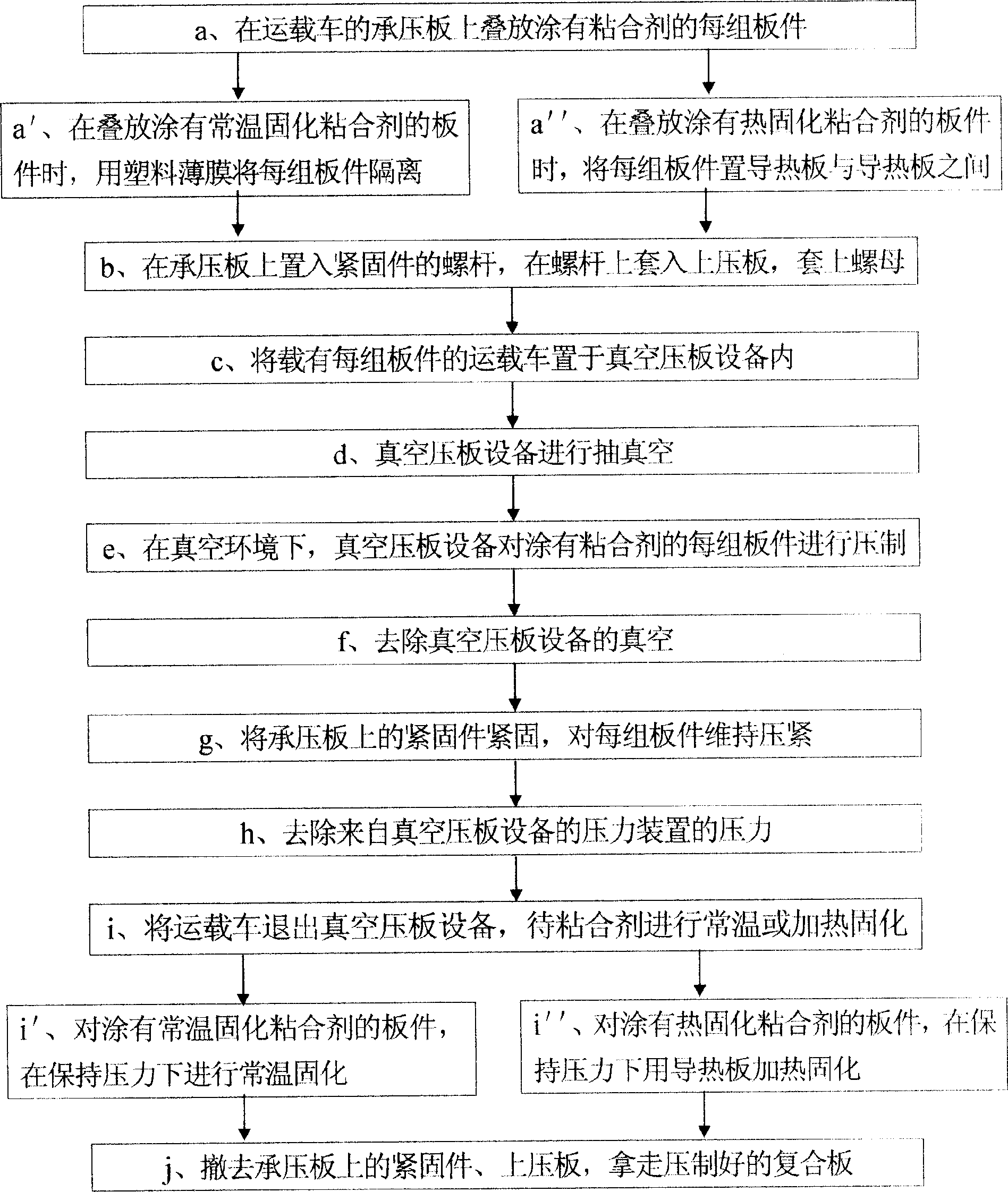

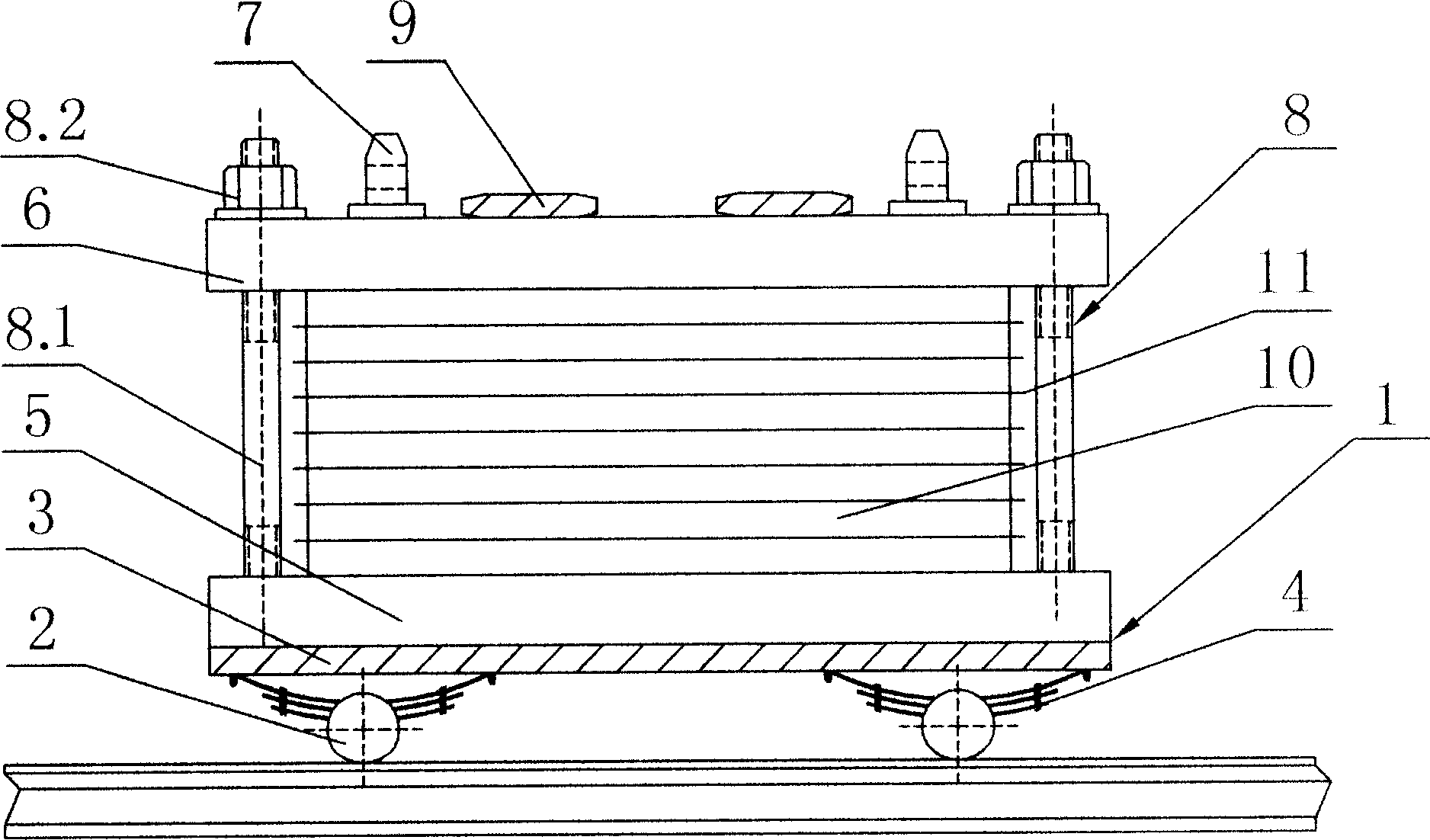

[0060] to combine figure 1 , figure 2 , Figure 4 , Figure 5 Further describe the method of the present invention:

[0061]Take 20 artificial stone slabs, 2 as a group, first apply SY-21 room temperature curing adhesive on the joint surface of the artificial stone slabs, and the joint surfaces are opposite; then stack each group of plates on the pressure plate 5 of the transport vehicle 1 Parts 10, use plastic film 11 to isolate each group of boards 10, so as to avoid adhesive seepage, so that each group of boards 10 and each group of boards 10 will be glued; after stacking each group of boards 10 , put the screw 8.1 of the fastener 8 on the pressure plate 5 of the carrier 1, and then insert the upper pressure plate 6 into the screw 8.1 to press each group of plates 10 and put on the nut 8.2. At this time, the nut 8.2 is in the In a relaxed state, the upper pressing plate 6 is made of cast iron; The guide post 7 of the pressing plate 6 is connected, and the upper pressi...

Embodiment 2

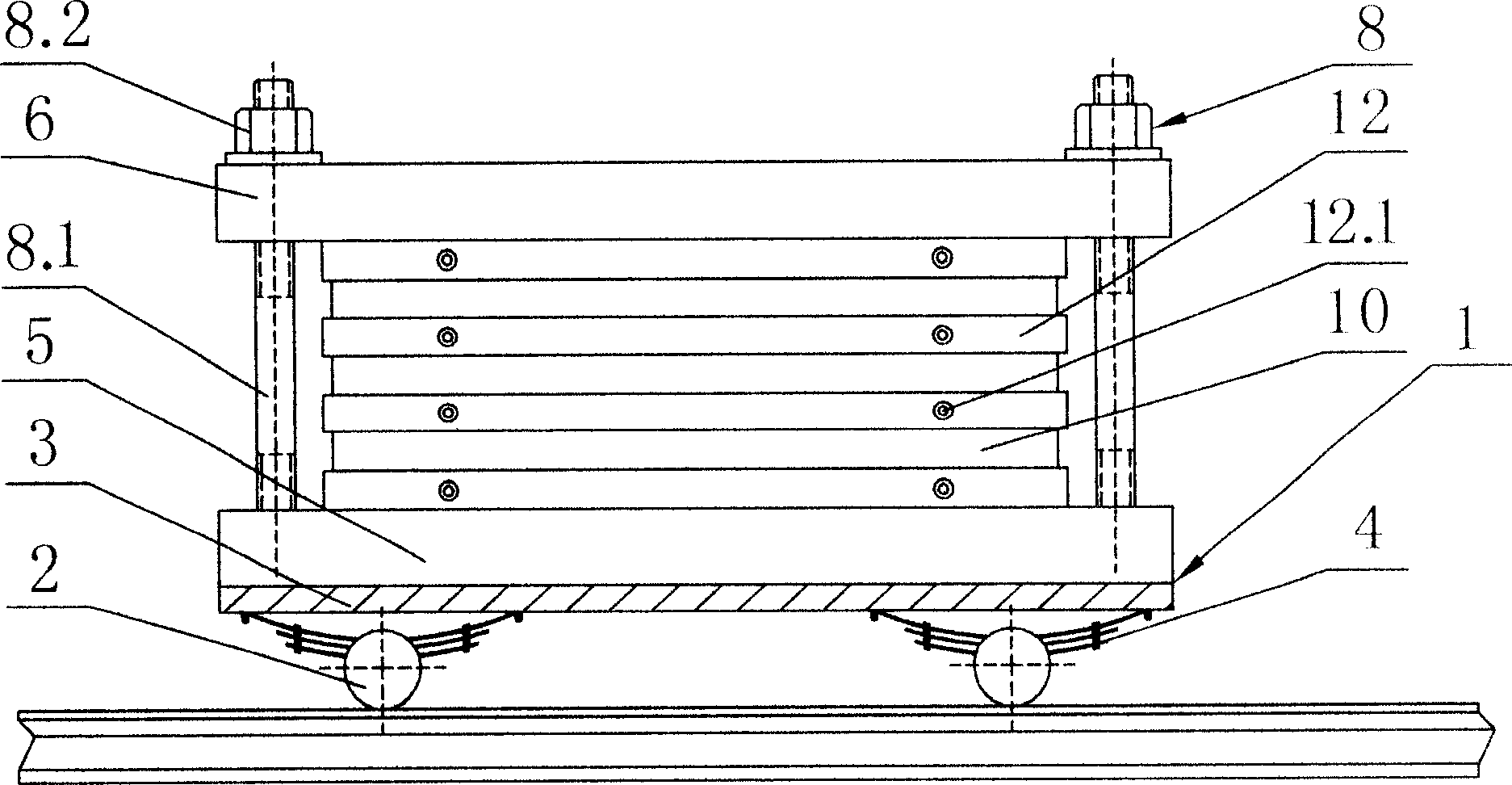

[0064] combine figure 1 , image 3 , Figure 6 , Figure 7 Further describe the method of the present invention:

[0065] Take 15 artificial stone boards and 15 fireproof boards, first apply E-7-2 heat-curing adhesive on the joint surface of the artificial stone boards and fireproof boards, and combine one artificial stone board with one fireproof board as a group. The combined surfaces are opposite; then each set of plates 10 is stacked on the pressure plate 5 of the transport vehicle 1, and each set of plates 10 is placed between the heat conducting plate 12 and the heat conducting plate 12; after stacking each set of plates 10 , put the screw 8.1 of the fastener 8 on the pressure plate 5 of the carrier 1, and then insert the upper pressure plate 6 into the screw 8.1 to press each group of plates 10 and put on the nut 8.2. At this time, the nut 8.2 is in the In a relaxed state, the upper platen 6 is cast with aluminum alloy; then the vehicle 1 carrying each set of plates...

Embodiment 3

[0068] combine figure 1 , figure 2 , Figure 8 Further describe the method of the present invention:

[0069] Take 5 marble slabs and 10 artificial stone slabs, first apply SY-21 room temperature curing adhesive on the joint surface of the slabs, one marble slab and 2 artificial stone slabs form a group, and the joint surfaces are opposite; Each set of plates 10 is stacked on the pressure bearing plate 5, and the method and steps for stacking each set of plates 10 are the same as in Embodiment 1. After stacking each set of plates 10, the cover-type vacuum platen equipment 18' is placed On the pressure-bearing plate 5 of the carrier vehicle 1, the vacuum cover sealing ring 19 of the cover-type vacuum platen device 18' is sealed and connected with the pressure-bearing plate 5 of the carrier vehicle 1, and then, through the cover-type vacuum platen device 18' Small door 14.2, connect the guide seat 15 of the liquid pressure device 13 with the guide post 7 of the upper platen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com