Helical centrifugal impeller with turbofan bucket and application method of the impeller in fluid transportation

A centrifugal impeller and scoop screw technology, which is applied to turbofan scoop screw centrifugal impeller and the application field of the impeller in fluid transportation, can solve the problems of improving design without substantial breakthrough, energy loss, needing diffuser return device and the like , to achieve the effect of strong transfer and conversion ability, energy saving and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

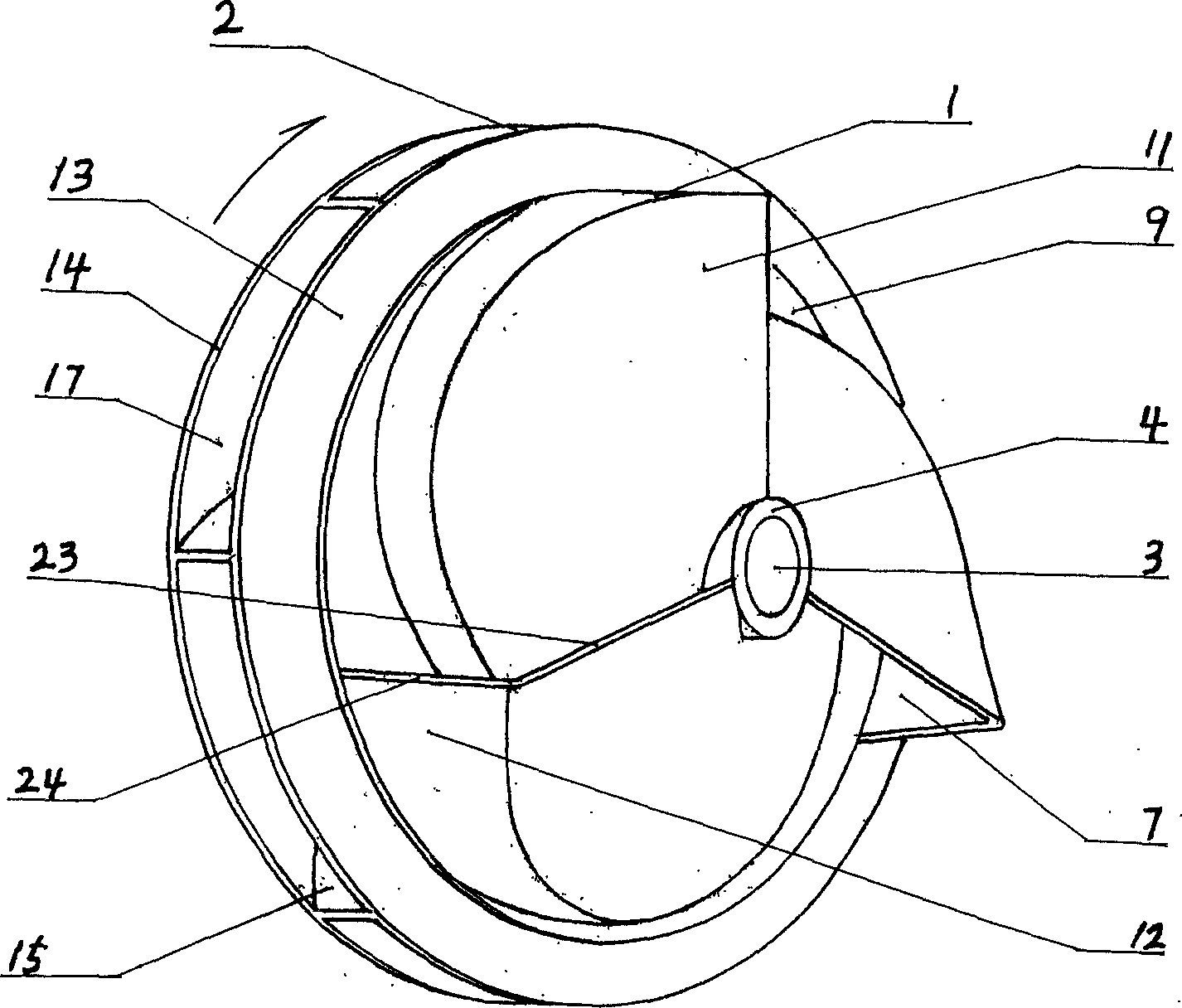

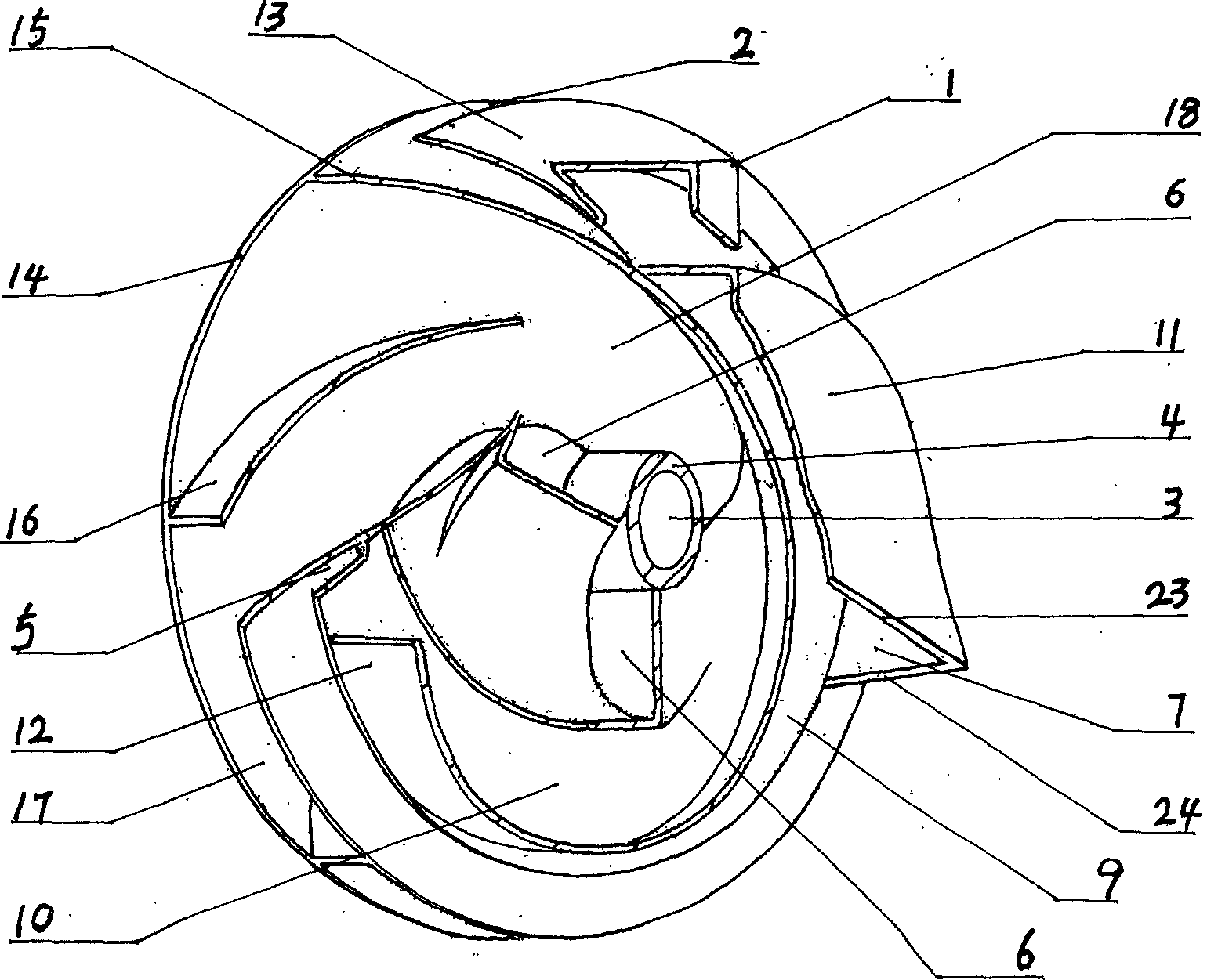

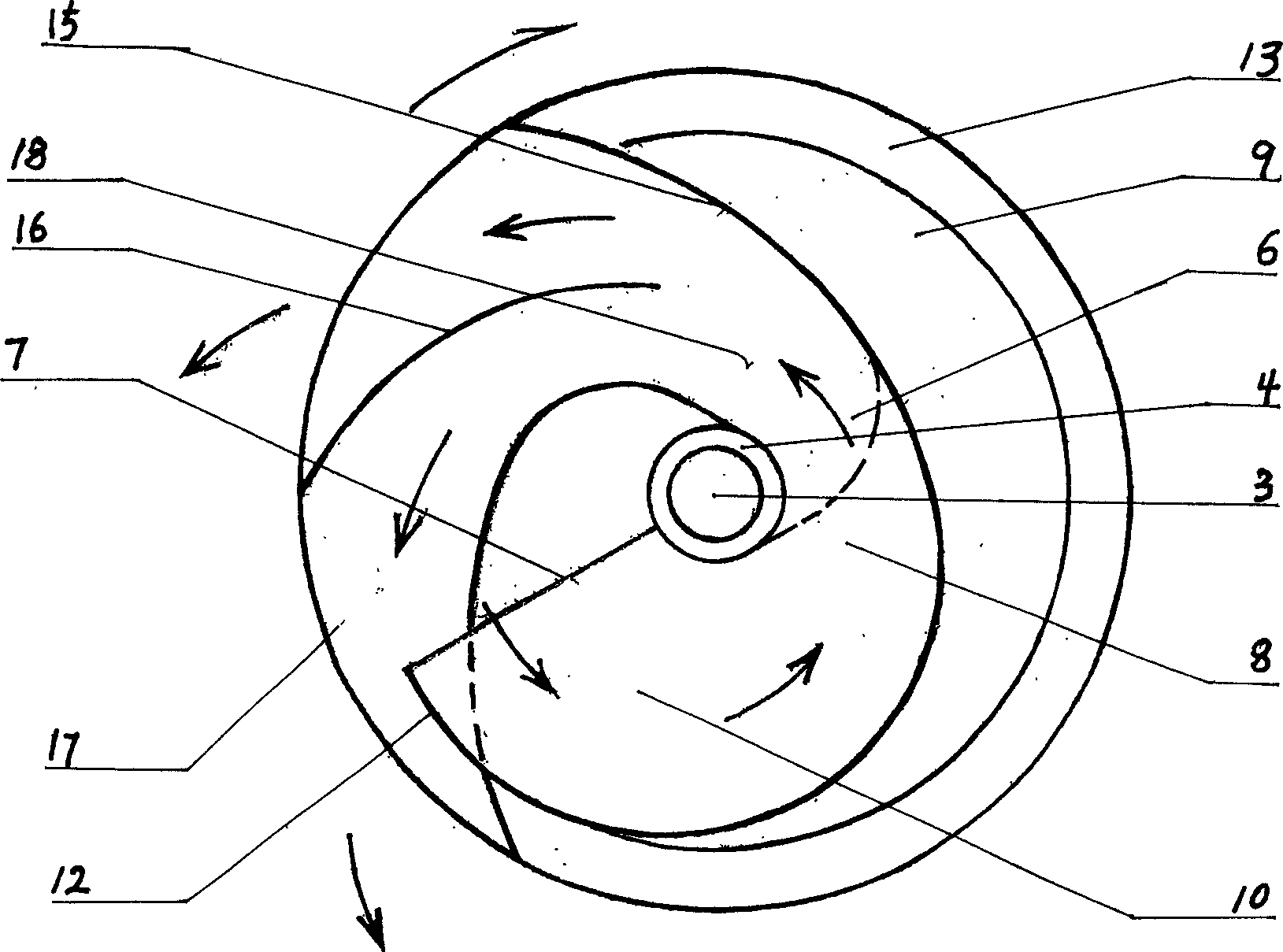

[0034] Hereinafter, the present invention will be further described through embodiments in conjunction with the accompanying drawings.

[0035] The embodiment is a turbofan bucket spiral centrifugal impeller with three main runners.

[0036] The turbofan bucket spiral centrifugal impeller consists of two stages forward and backward in the overall axial direction. The front turbofan bucket impeller is a flat cylindrical shape for the fluid cut and gathers the vortex pressure part and the back stage spiral centrifugal impeller is the fluid centrifugal thrown part. To the center of the circular surface, there is a shaft hole and a large outer diameter hub that penetrates the central axis of the front and rear impellers. Between the front stage turbofan bucket impeller and the rear stage spiral centrifugal impeller, there is an outer circle surrounding the integral impeller on the radial periphery. One-week isolation seal groove, in the radial center, there are three common main chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com