Nerval net based inverse control system for permanent-magnet synchronous motor with five degrees of freedom without bearing and control method

A permanent magnet synchronous motor, neural network inverse technology, applied in general control systems, control/regulation systems, synchronous machines, etc., can solve the problems of no patents and literature, and achieve the effect of power improvement, practical structure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

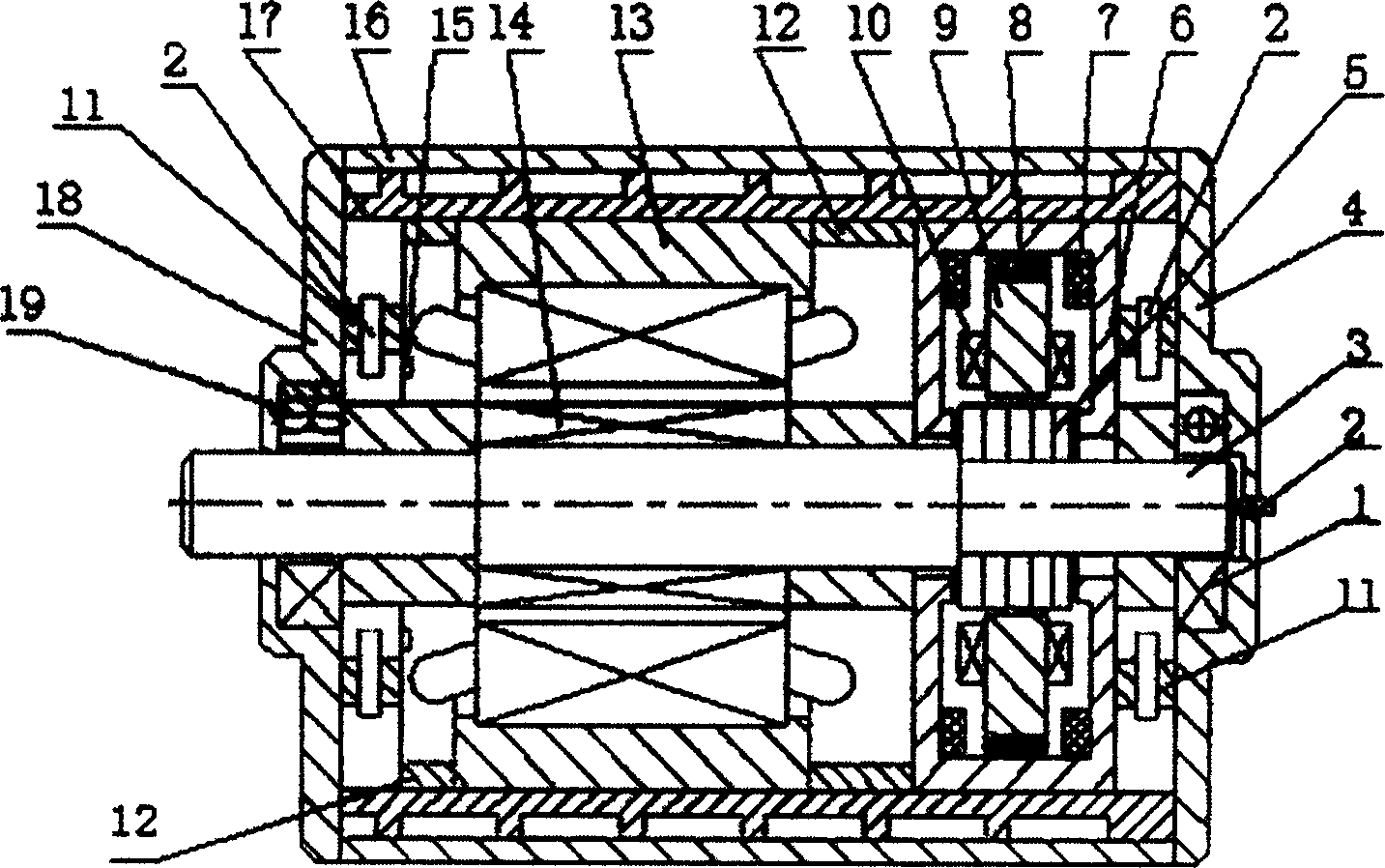

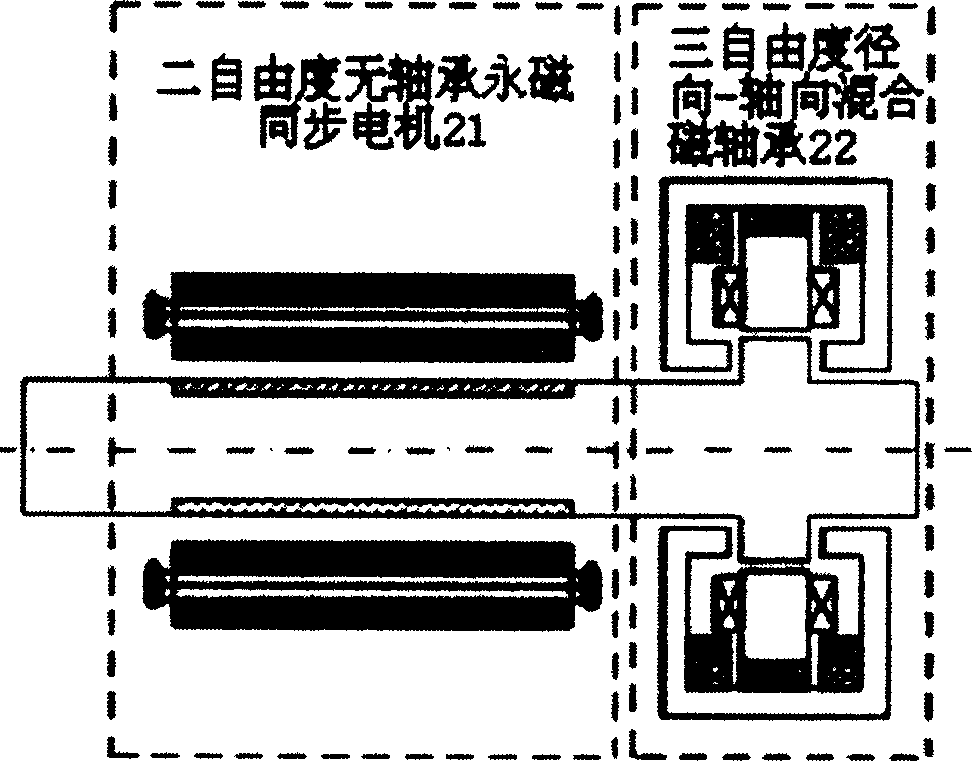

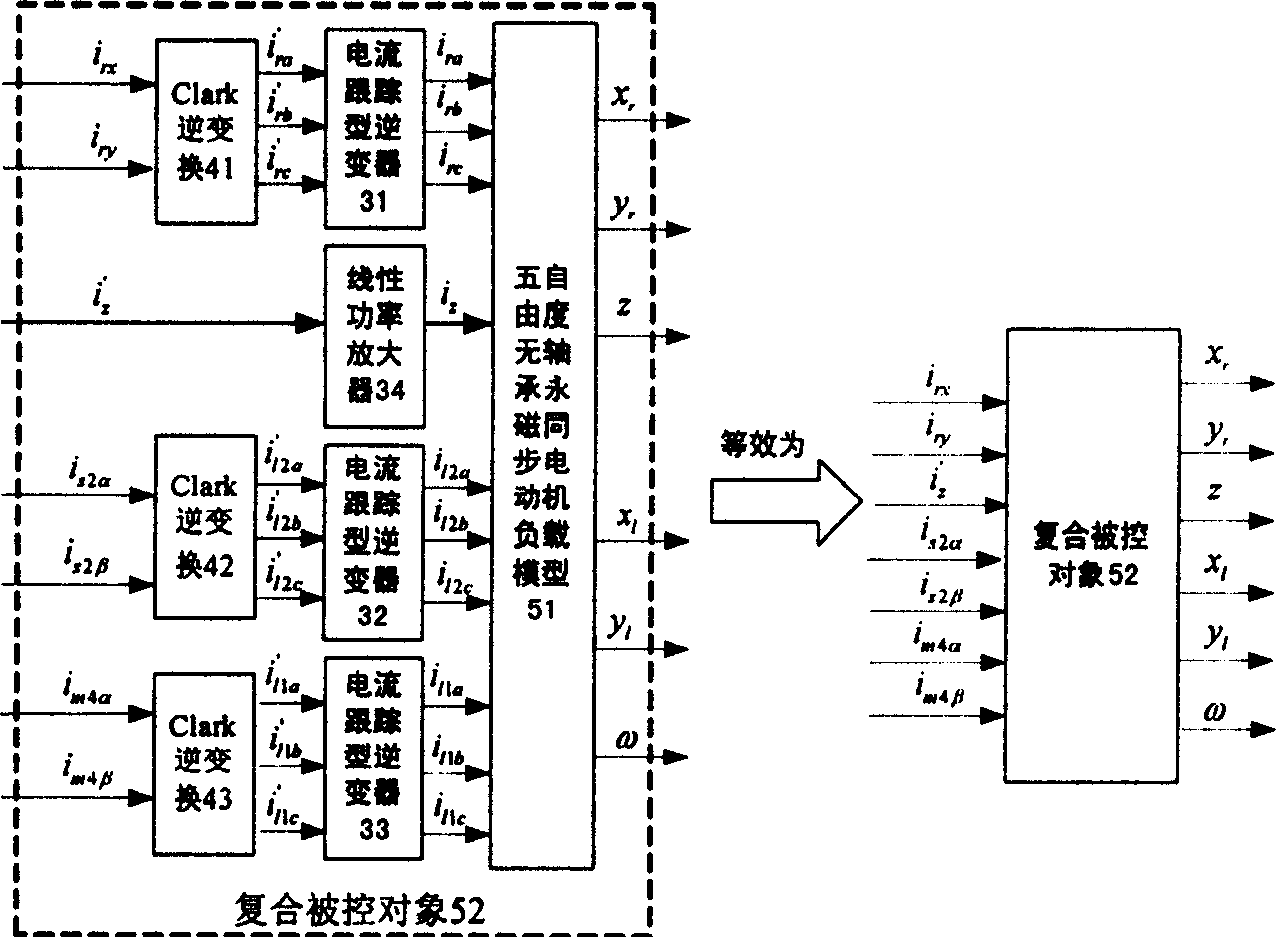

[0027] The embodiment of the present invention is as follows: first, a five-degree-of-freedom bearingless permanent magnet synchronous motor prototype body is constructed based on a three-degree-of-freedom AC-DC radial-axial hybrid magnetic bearing and a two-degree-of-freedom bearingless permanent magnet synchronous motor, and then three A Clark inverse transform, three current tracking inverters, a linear power amplifier, a five-degree-of-freedom bearingless permanent-magnet synchronous motor and a load form a composite controlled object as a whole, and the composite controlled object is equivalent to The 11th order differential equation model of , the relative order of the system vector is {2, 2, 2, 2, 2, 1}. Static neural network (3-layer network) with 17 input nodes and 7 output nodes plus 11 integrators -1 Construct the neural network inverse of a compound plant with 6 input nodes and 7 output nodes. And by adjusting the weights of the static neural network, the neural n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com