Method for conducting catalytic reaction in ultragravity field

A technology of catalytic reaction and high-gravity rotating bed, which is applied in chemical instruments and methods, chemical/physical/physical-chemical mobile reactors, chemical/physical processes, etc., to achieve small particle size, shortened residence time, and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The C4 fraction is fully hydrogenated in a rotating bed reactor in a supergravity field. The full hydrogenation of the C4 fraction is a gas-liquid-solid three-phase reaction, and the material used is H 2 , C4 fraction (the components are: butane, butene, butadiene and butyne), the catalyst is Pd / Al 2 o 3 , Temperature: 10~180°C, Pressure: 2~40atm, Speed 800~2100rpm. C4 space velocity 10~500hr-1, hydrogen / unsaturated bond (butene+2×butadiene+2×butyne+3×vinylethylene): 1.0~1.2mol / mol, circulation ratio: 5~9: 1.

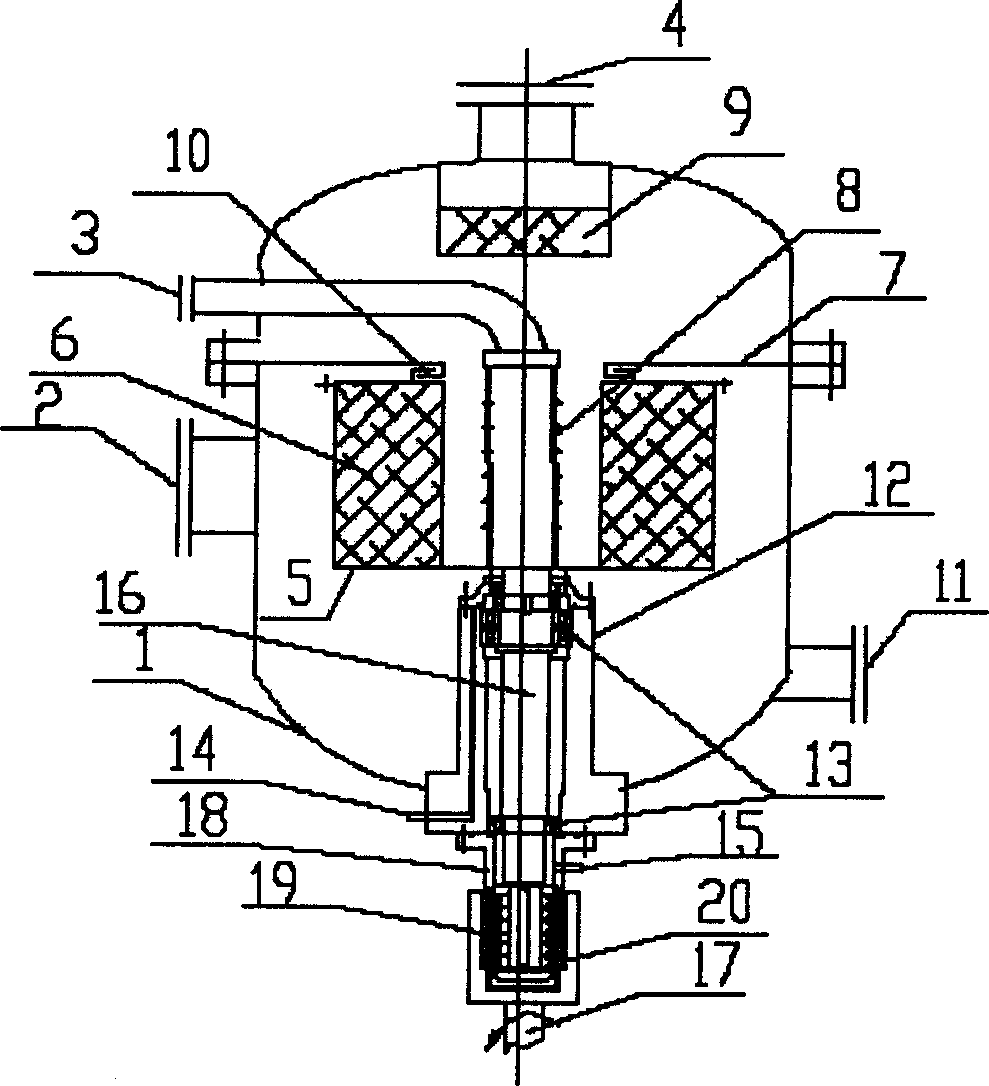

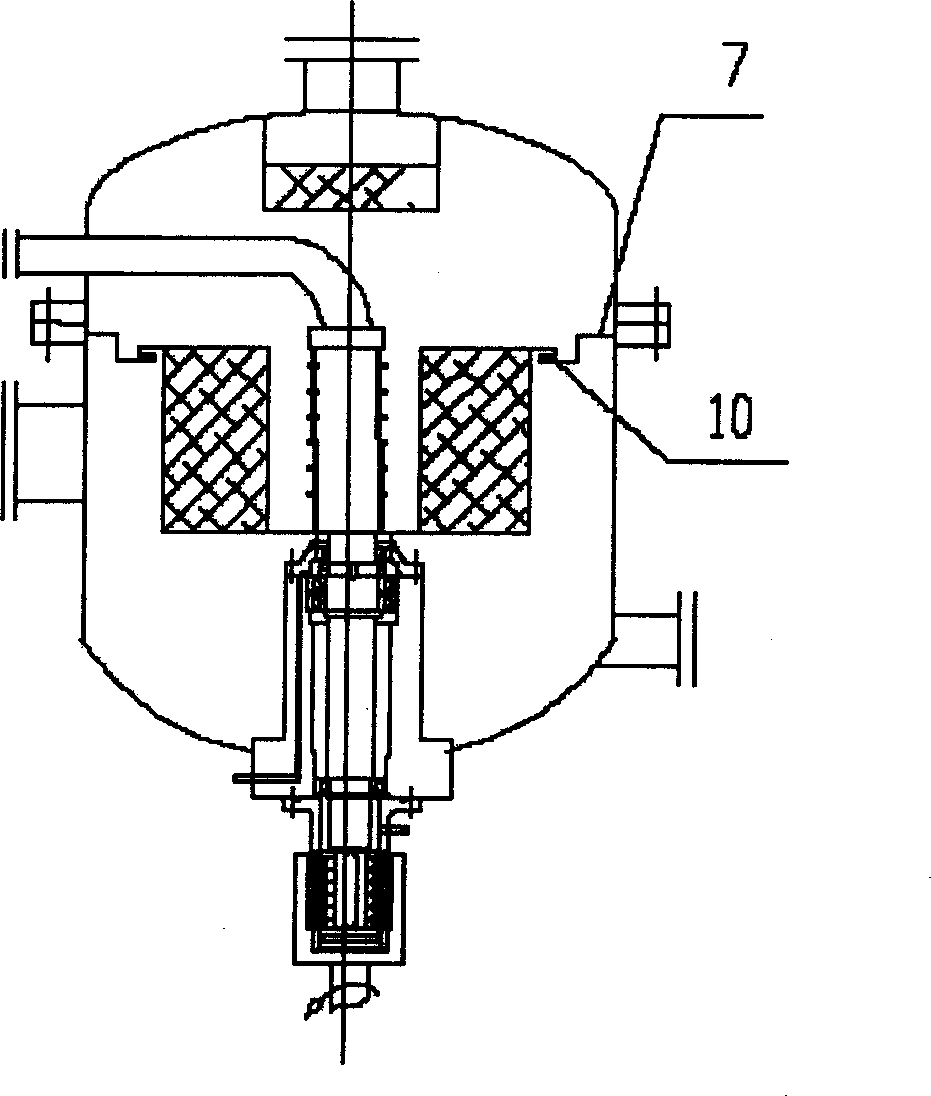

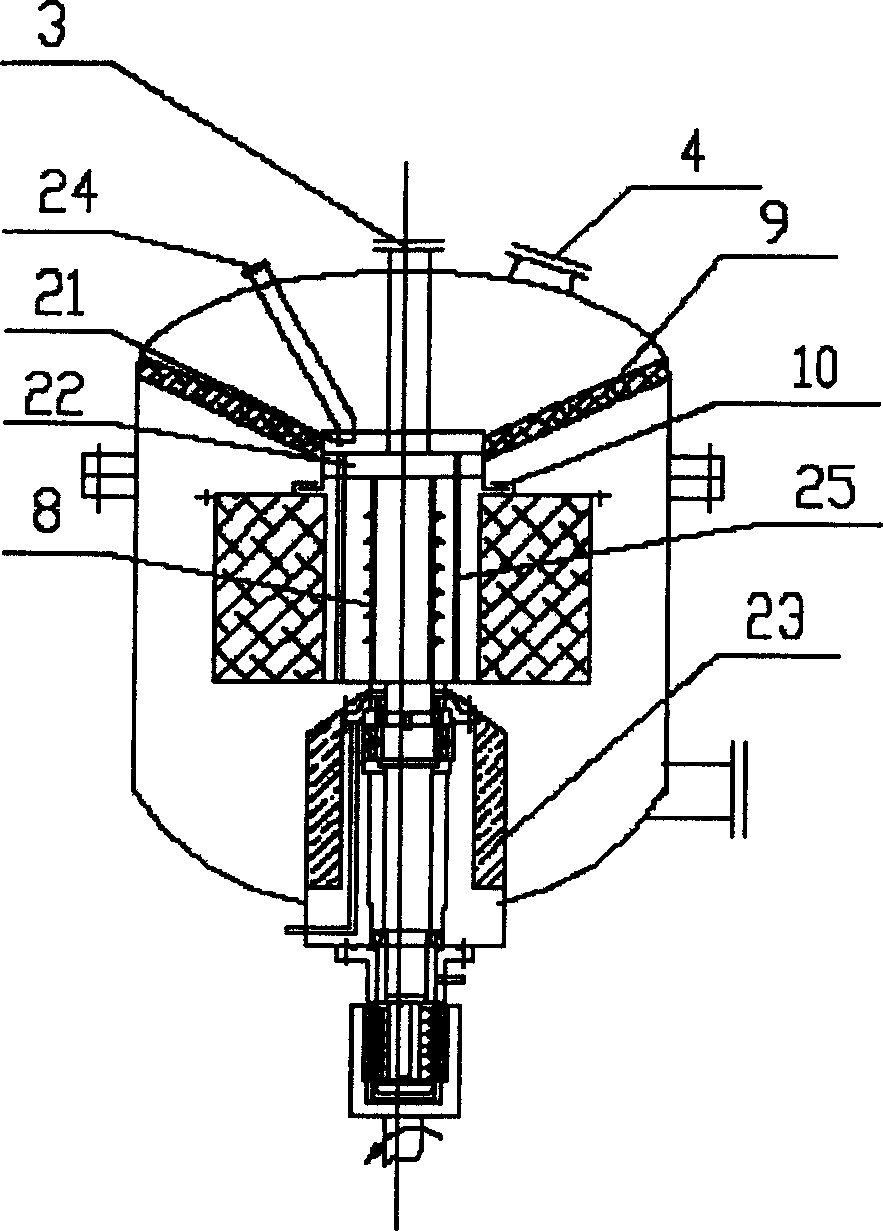

[0033] The high gravity rotating bed reactor adopts such as figure 2 The structure shown, the process is as follows Figure 4 As shown, a catalyst with an average particle size of 40 μm containing 0.4% (wt) Pd (made of Al by sol-gel method) 2 o 3 , spray-dried to obtain Al 2 o 3 Powder, sieved to obtain a carrier with an average particle size of 40 μm, and the catalyst) 15ml was suspended in the C4 raw material liquid by sieving, and hydrogen was intr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com