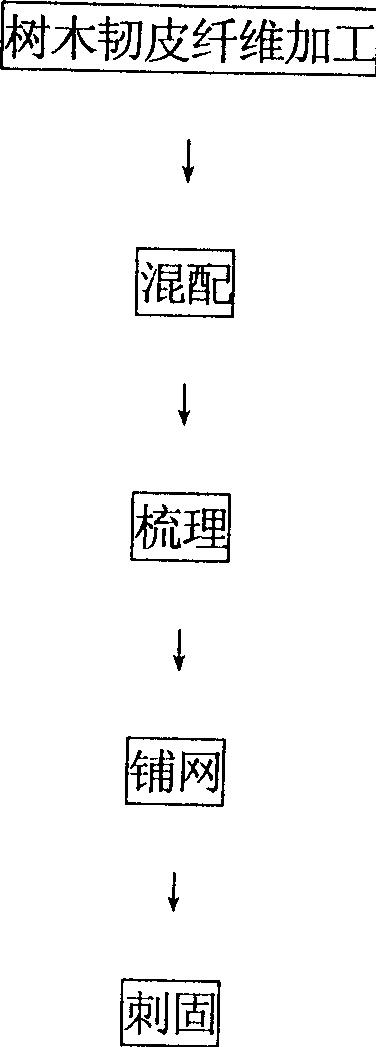

Tree bast fiber non-woven cloth and its processing method

A technology of bast fiber and processing method, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problem that it is impossible to provide mulberry bark, and achieve huge economic and social benefits, wide application and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

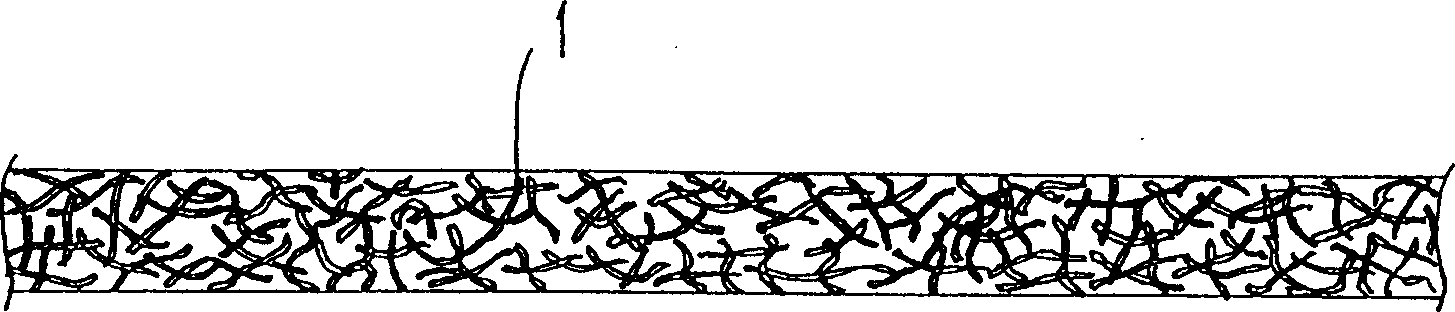

[0023] Such as figure 2 Shown, the tree bast fiber nonwoven fabric of the present invention is made of the tree bast fiber 1 of 100% by weight, and the length of the tree bast fiber 1 is 15~40mm, fineness 0.5~1.5D; The skin fibers 1 are evenly mixed with each other, interspersed and interwoven to form a three-dimensional net-like braided structure. The specific processing methods of non-woven fabrics are as follows:

[0024] (1) Tree bast fiber processing: the freshly felled spruce trees are processed by peeling → sorting → degumming → removing slag and impurities → drying → health preservation → tanning → crushed stems → combing → drying → boxing and grading. Tree bast fiber 1 with a length of 15-40mm and a fineness of 0.5-1.5D.

[0025] (2) Compounding: 5% talcum powder is mixed into the bast fiber 1, and the traditional compounding machine is used to carry out two compoundings.

[0026] (3) Carding: carding carried out according to the existing traditional cotton spinni...

Embodiment 2

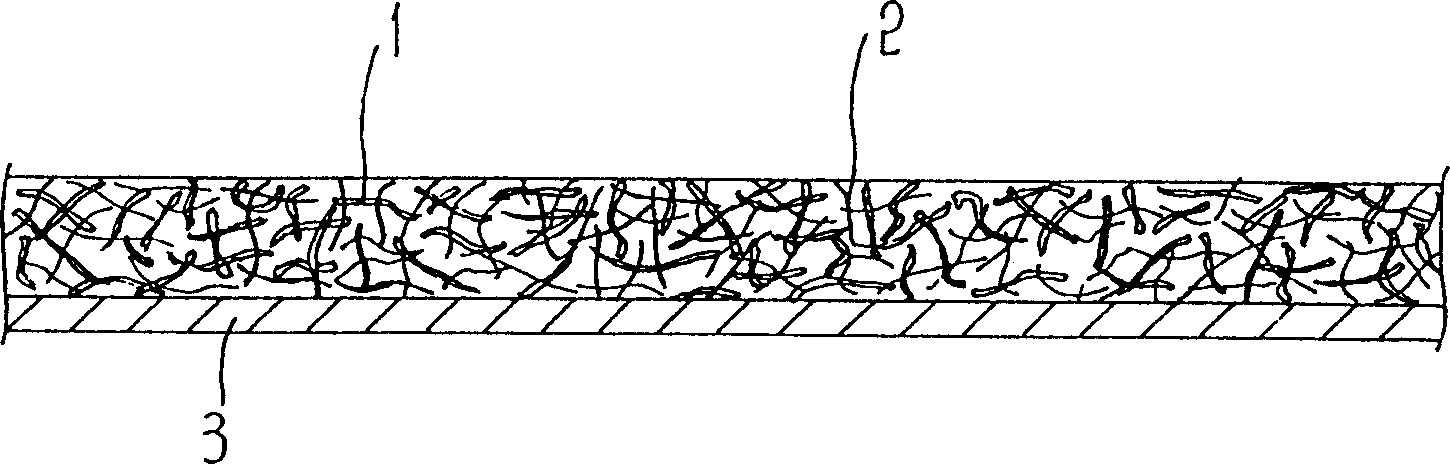

[0030] Such as image 3 Shown in, the tree bast fiber nonwoven fabric of the present invention is made up of the tree bast fiber 1 of 70% weight part and the ramie fiber 2 of 30% weight part, and the length of tree bast fiber 1 is 10~35mm, The fineness is 0.3-2D; the length of the ramie fiber 2 is 5mm-45mm, and the fineness is 0.3D-2.5D. Tree bast fibers 1, ramie fibers 2, and tree bast fibers 1 and ramie fibers 2 interpenetrate and interweave to form a three-dimensional net-like weaving structure; a nylon net-like bottom is also provided under the non-woven fabric. cloth3. The specific processing methods of non-woven fabrics are as follows:

[0031] (1) Tree bast fiber processing: the newly felled banyan tree branches are peeled → sorted → degummed → slag and impurity removed → dried → health → tanning → broken stems → combing → drying → binning and grading to form lengths Tree bast fiber 10-35mm, fineness 0.3-2D.

[0032] (2) Compounding: 70% of the tree bast fiber 1 was...

Embodiment 3

[0037] Such as Figure 4 As shown, the tree bast fiber nonwoven fabric adopts 50% by weight of tree bast fiber 1 and 50% by weight of cotton fiber 2. The length of tree bast fiber 1 is 20-40mm, and the fineness is 1.5D-2.5 D; Tree bast fibers 1, cotton fibers 2, and tree bast fibers 1 and cotton fibers 2 interweave and interweave to form a three-dimensional network weaving structure; on the upper surface, middle and The lower surface is also provided with three layers of nylon mesh base cloth 3 . The specific processing methods of non-woven fabrics are as follows:

[0038] (1) Tree bast fiber processing: the freshly felled oleander is processed by peeling→sorting→degumming→removing slag and impurities→drying→health→tanning→broken stems→combing→drying→boxing and grading. Tree bast fiber 1 with a length of 20-40mm and a fineness of 1.5-2.5D.

[0039] (2) Mixing: After mixing 50% of the tree bast fiber 1 with 3% talcum powder and 50% by weight of the cotton fiber 2, the tradit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com