Intelligent optimizing set during process of shaft roasting

A technology of intelligent optimization and setting methods, which is applied in the direction of furnaces, vertical furnaces, furnace types, etc., can solve the problems of waste of raw materials, metal recovery rate, difficulty in guaranteeing and reducing roasting quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

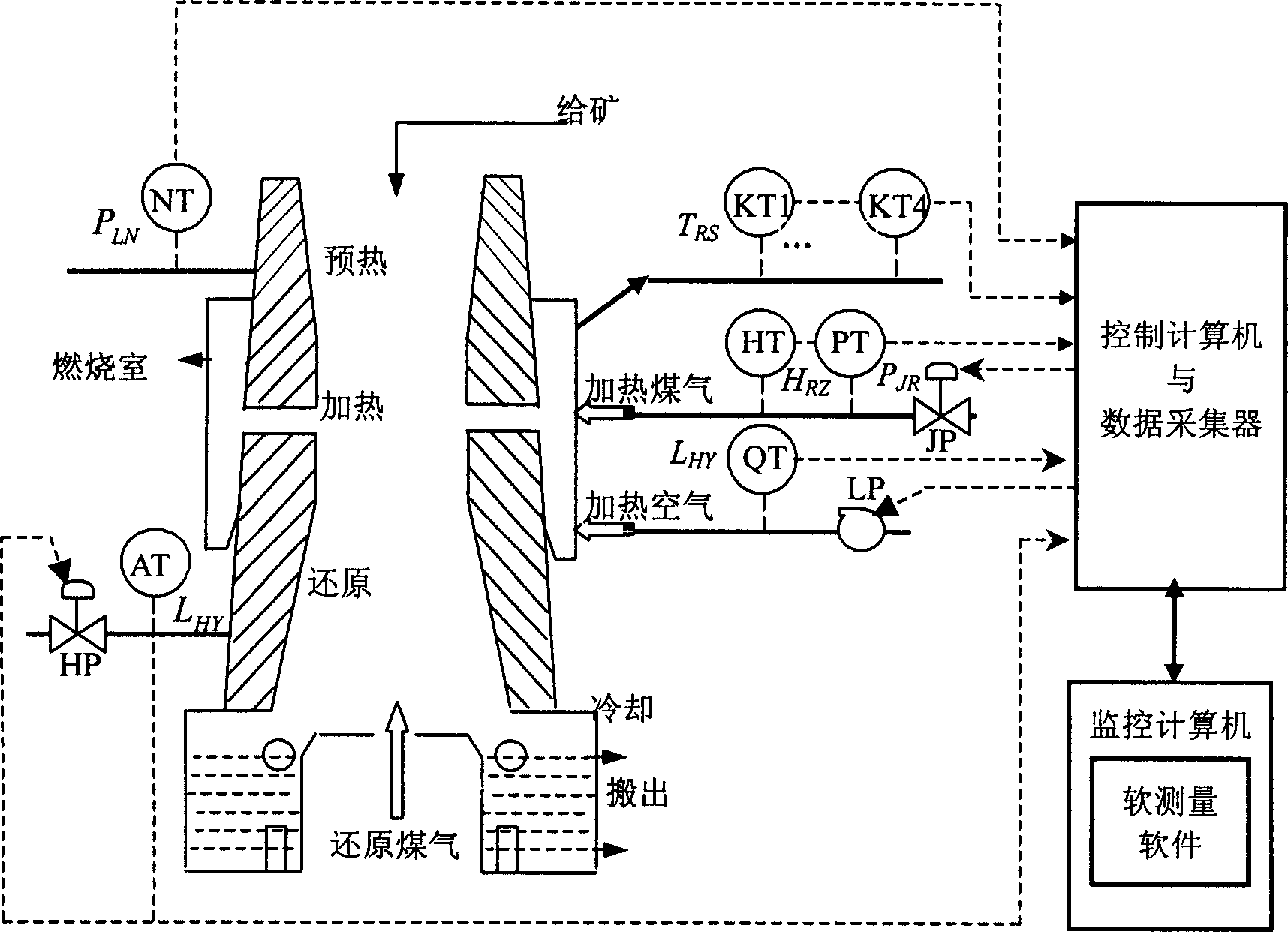

[0104] Taking the shaft furnace magnetization roasting section of a large-scale iron ore dressing plant as an example, the main iron ore of the dressing plant is pyrite and limonite, and the gangue is mainly barite, quartz, jasper and iron dolomite. The actual iron grade of the ore is 33%. The purpose of the shaft furnace roasting is to convert the weakly magnetic hematite (Fe 2 o 3 ) reduced to strong magnetic magnetite (Fe 3 o 4 ), so that it can be sorted on a magnetic separator with low magnetic field strength for sorting out strong magnetic minerals, so as to improve the metal recovery rate.

[0105] Install the following measuring instruments according to the requirements of this manual, including:

[0106] Four NiCrSi-NiSiMg thermocouples for online measurement of combustion chamber temperature T RS ;

[0107] A Verabar flowmeter for online measurement of heating gas flow L JR ;

[0108] A Verabar flowmeter for online measurement of the heating air flow L KQ ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com