Laser projector

A laser projector and laser light source technology, applied in the field of laser projectors, can solve the problems of high production cost, color border, high heat, etc., and achieve the effects of fast speed, high gray level, and high light utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

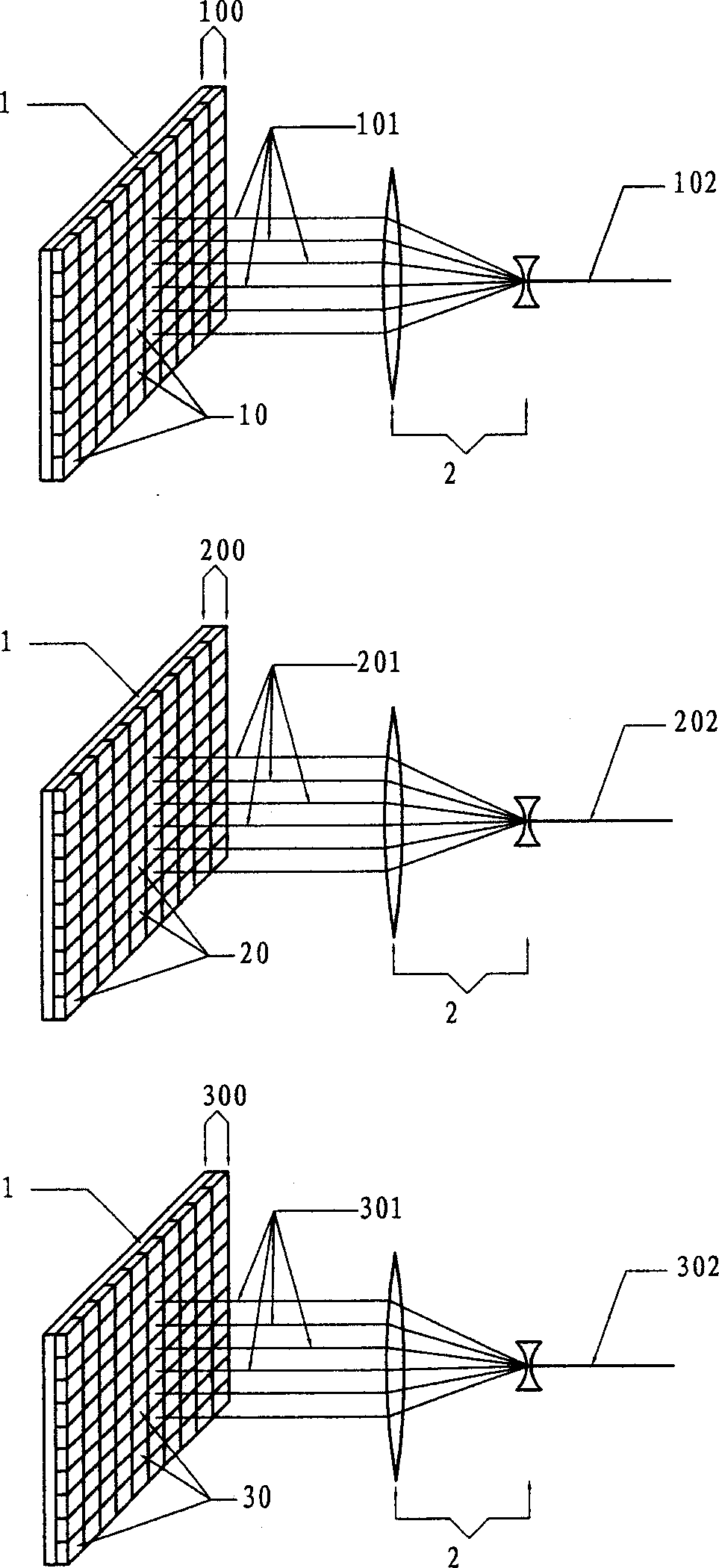

[0038] figure 1 Middle: The upper figure shows that multiple red laser diodes 10 are installed on the substrate 1 and arranged in a plate shape to form a red laser light source plate 100. 100 emits multiple parallel laser beams 101, enters the converging lens group 2, and converges into a red color. The total light beam 102; the middle figure shows that a plurality of green laser diodes 20 are installed on the substrate 1 and arranged in a plate shape to form a green laser light source board 200, which emits a plurality of parallel laser beams 201, enters the converging lens group 2, and converges into a green total light beam 202; the figure below shows that multiple blue laser diodes 30 are installed on the substrate 1 and arranged in a plate shape to form a blue laser light source plate 300, which emits multiple parallel laser beams 301 and enters the converging lens Group 2, converging into a blue total light beam 302 .

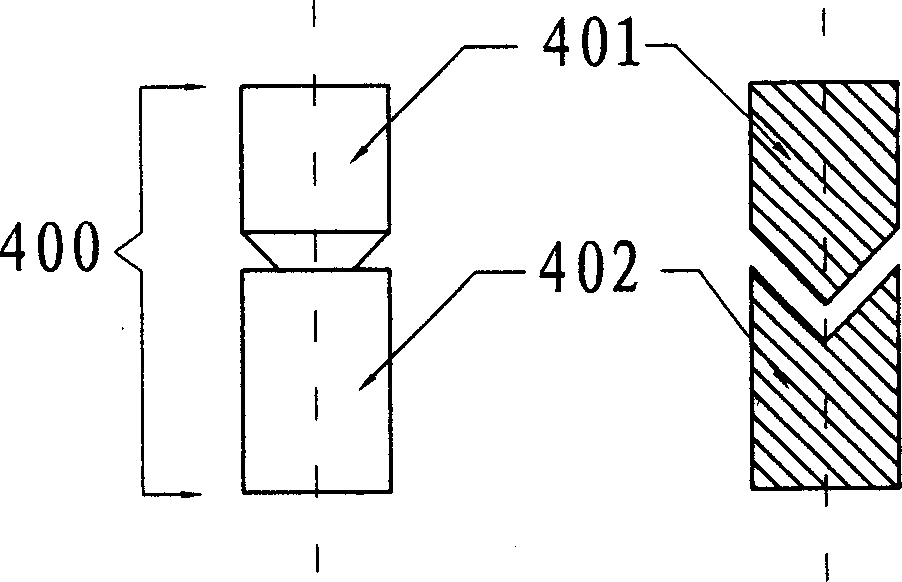

[0039] like figure 2 As shown: the convex surfac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap