Electron ballast passive power factor correcting circuit

A technology of passive power factor and electronic ballast, which is applied in the direction of electric light source, AC power input conversion to DC power output, output power conversion device, etc., which can solve the problems that integrated fluorescent lamp components cannot be used and the cost is high. Achieve the effect of simple structure and improved life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

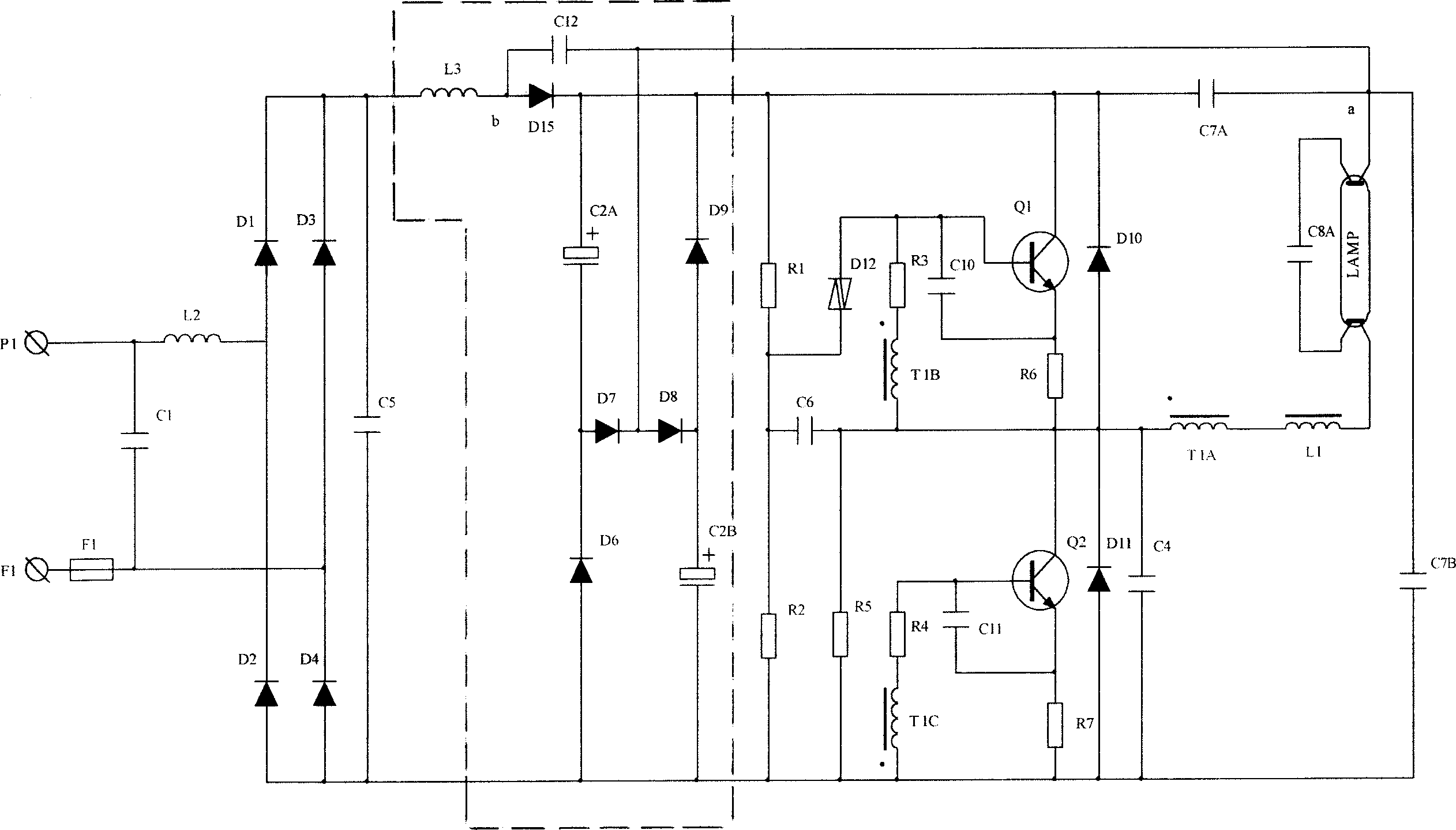

[0017] refer to figure 1 , the electronic ballast circuit includes a power input circuit, a passive power factor correction circuit and a DC / AC conversion circuit, wherein the power input circuit includes a filter circuit composed of capacitor C1 and inductor L2 and a filter circuit composed of D1, D2, D3, D4 Full-wave rectification circuit and capacitor C5. The DC / AC conversion circuit includes a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, a resistor R6, a resistor R7, a capacitor C4, a capacitor C6, a capacitor C10, a capacitor C11, a DC blocking capacitor C7A, and a DC blocking capacitor C7B, capacitor C8A, diode D10, diode D11, bidirectional trigger diode D12, oscillating coil T1A, oscillating coil T1B, oscillating coil T1C, inductor L1, transistor Q1 and transistor Q2.

[0018] The passive power factor correction circuit includes a BOOST circuit and a flow-by-stream circuit. The BOOST circuit includes an inductor L3, a capacitor C12 and a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com