Self-modulating inert gas gire suppression system

A technology for gas and gas regulation, applied in pipeline systems, gas treatment applications, gas/liquid distribution and storage, etc., can solve expensive and other problems, and achieve the effect of economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

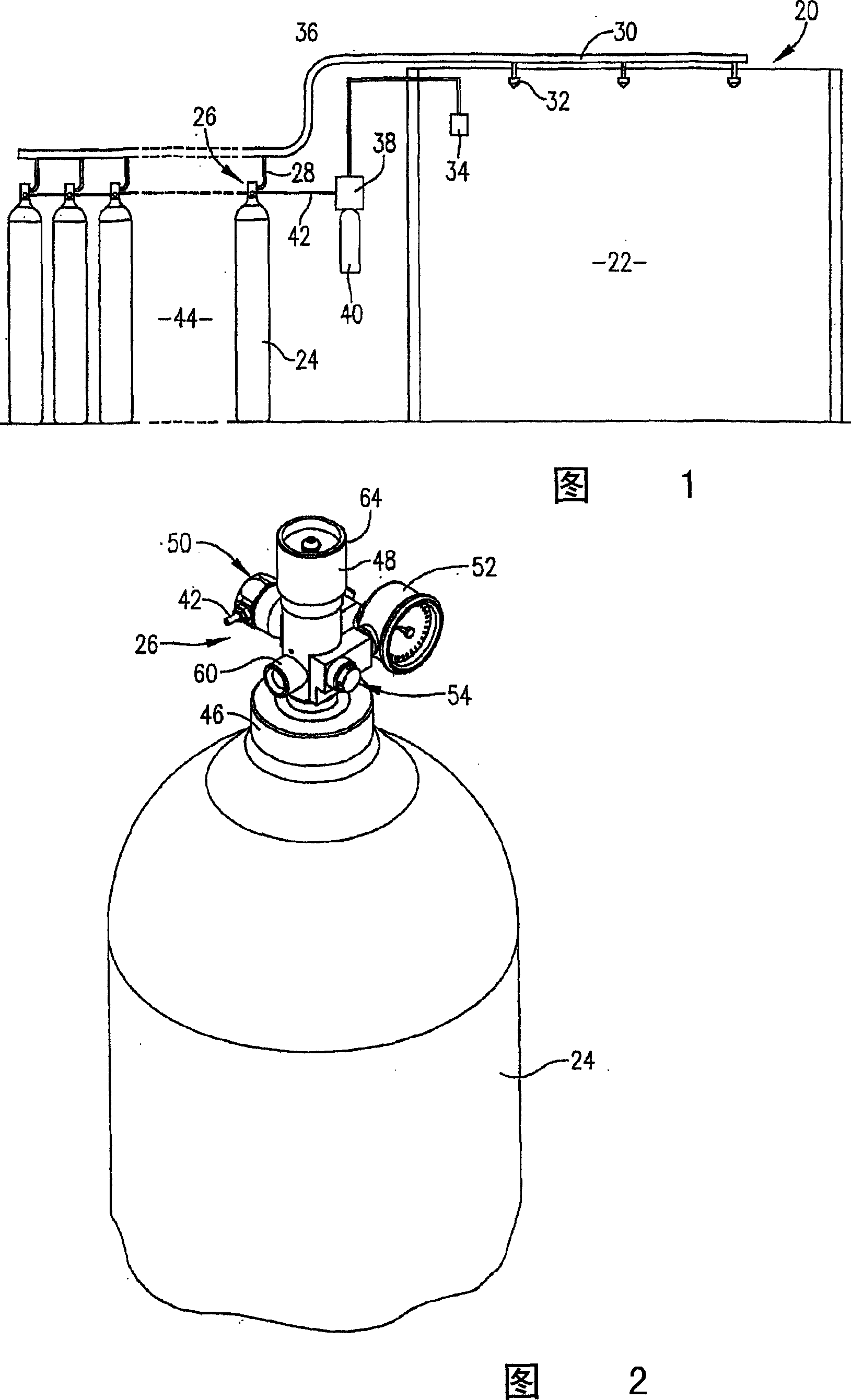

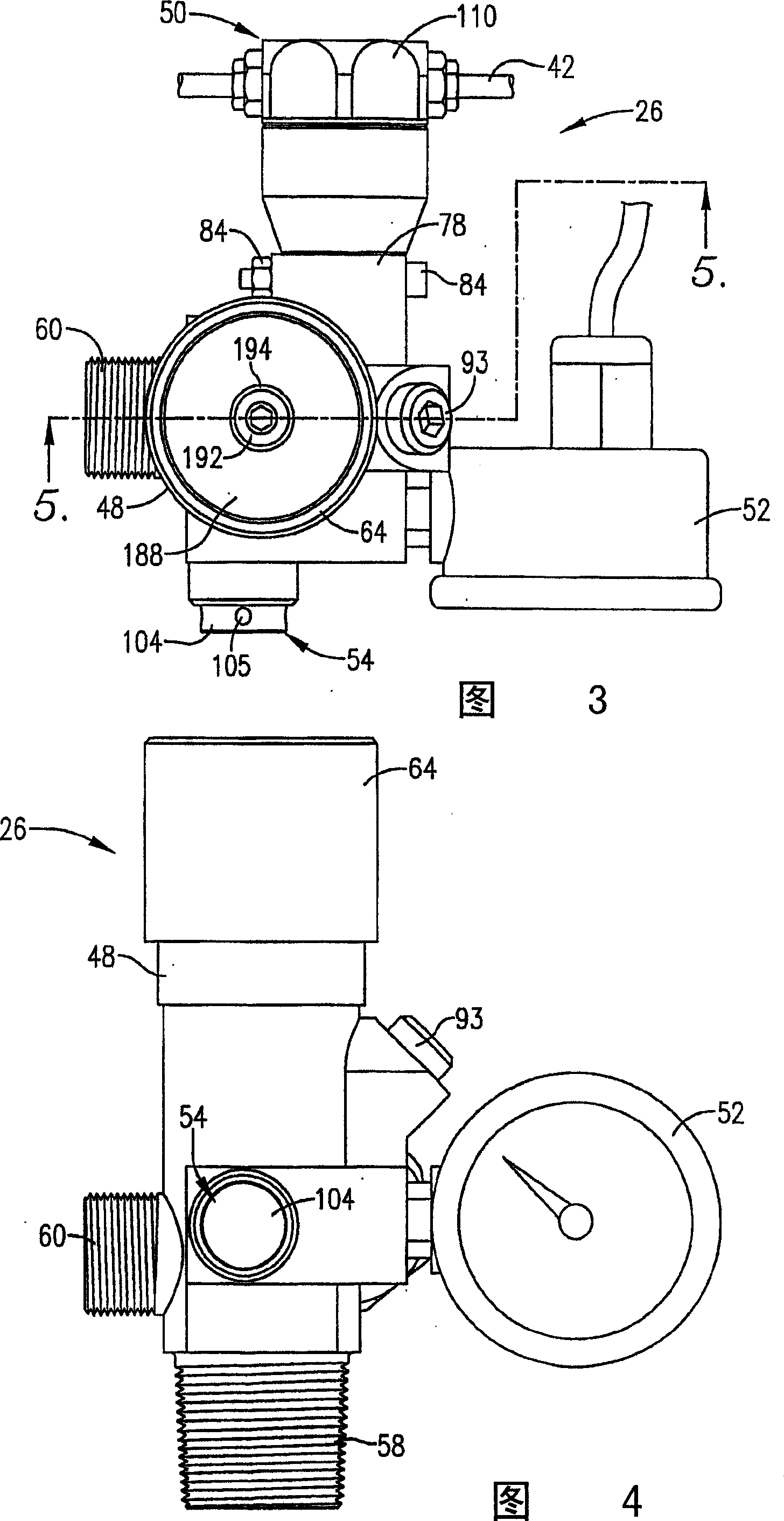

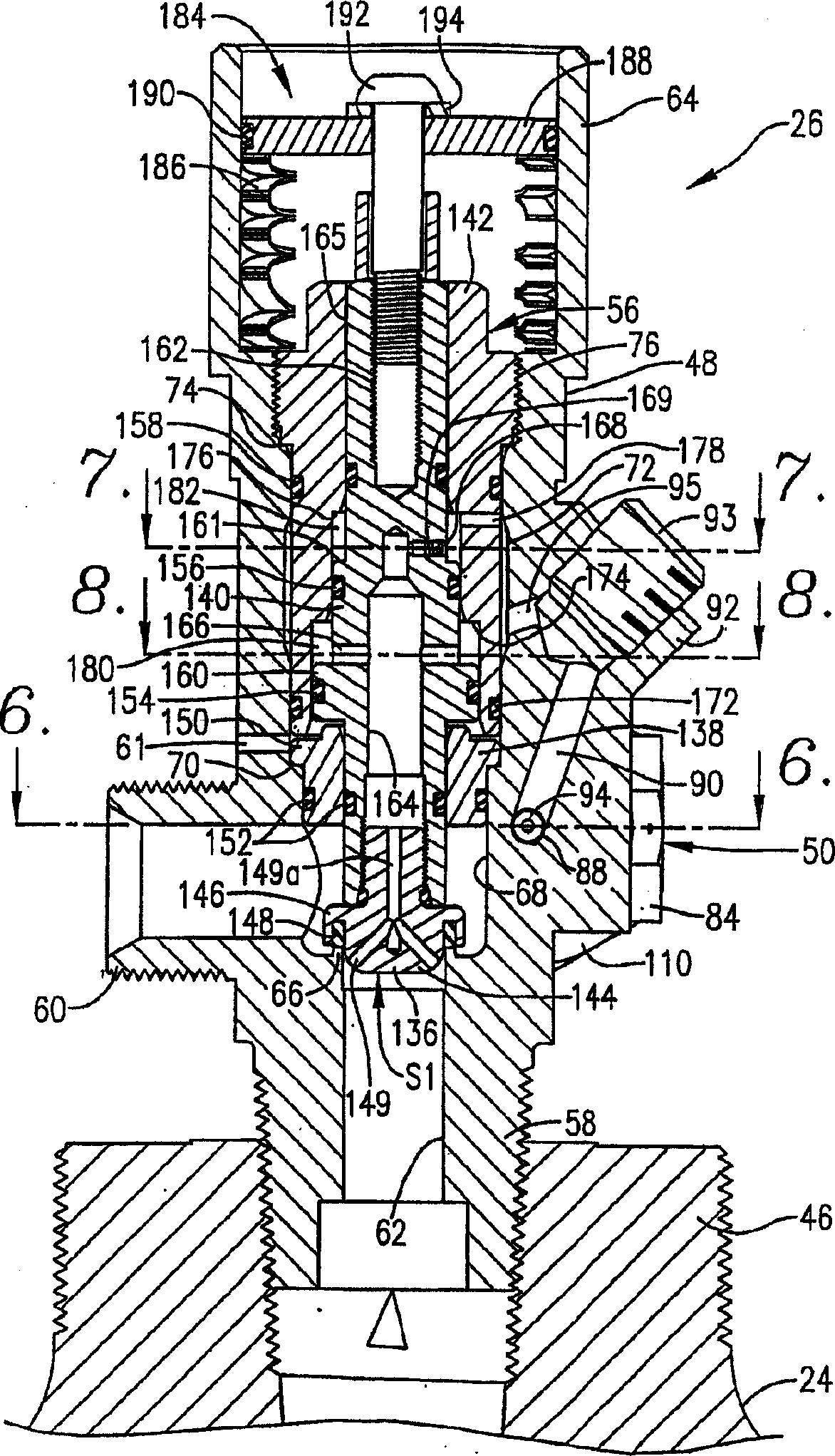

[0029]Referring now to the drawings, a hazard suppression system 20 is schematically shown in FIG. 1 . System 20 is designed to protect an enclosed room 22 where computer equipment or other valuable equipment may be housed. Generally, the system 20 includes a plurality of high pressure inert gas cylinders 24 each containing a valve unit 26 . Each valve unit 26 is connected to a manifold assembly 30 by a conduit 28 . As shown, assembly 30 extends into room 22 and incorporates a plurality of nozzles 32 for delivering inert gas into room 22 to suppress hazards. The piping that makes up the system 30 may be conventional 40 gauge pipe, as opposed to the heavy duty 160 gauge manifolds and pressure reducing orifice plates required by prior art systems of this type. The overall system 20 also includes a hazard detector 34 connected by a cable 36 to a solenoid valve 38 . Solenoid valve 38 is operably connected to a small gas cylinder 40, typically containing pressurized nitrogen or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com