Plate heat exchanger

A technology of plate heat exchangers and heat exchangers, applied in the direction of indirect heat exchangers, heat exchanger types, heating methods, etc., can solve problems such as large energy consumption, and achieve the effect of easy maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

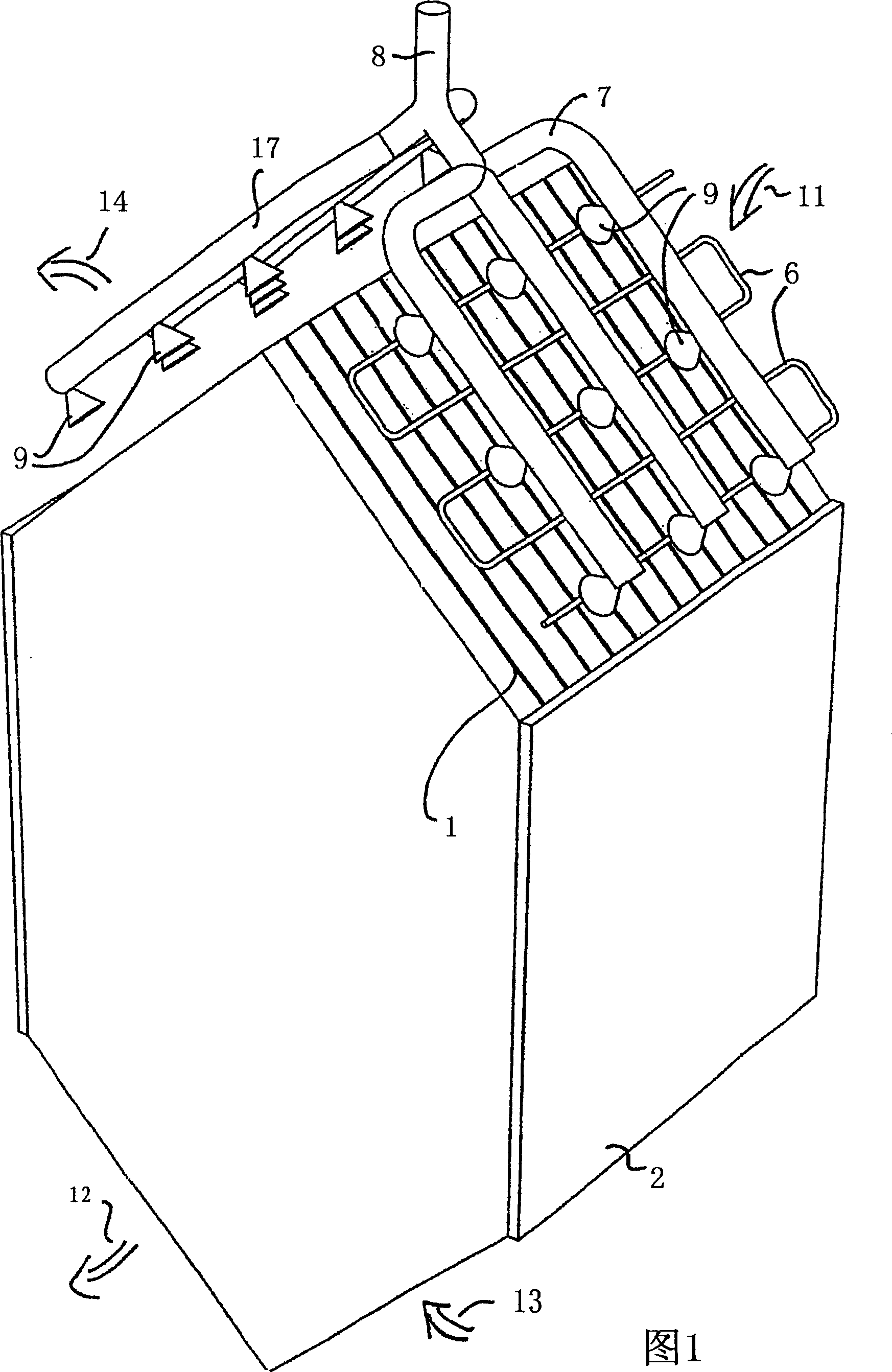

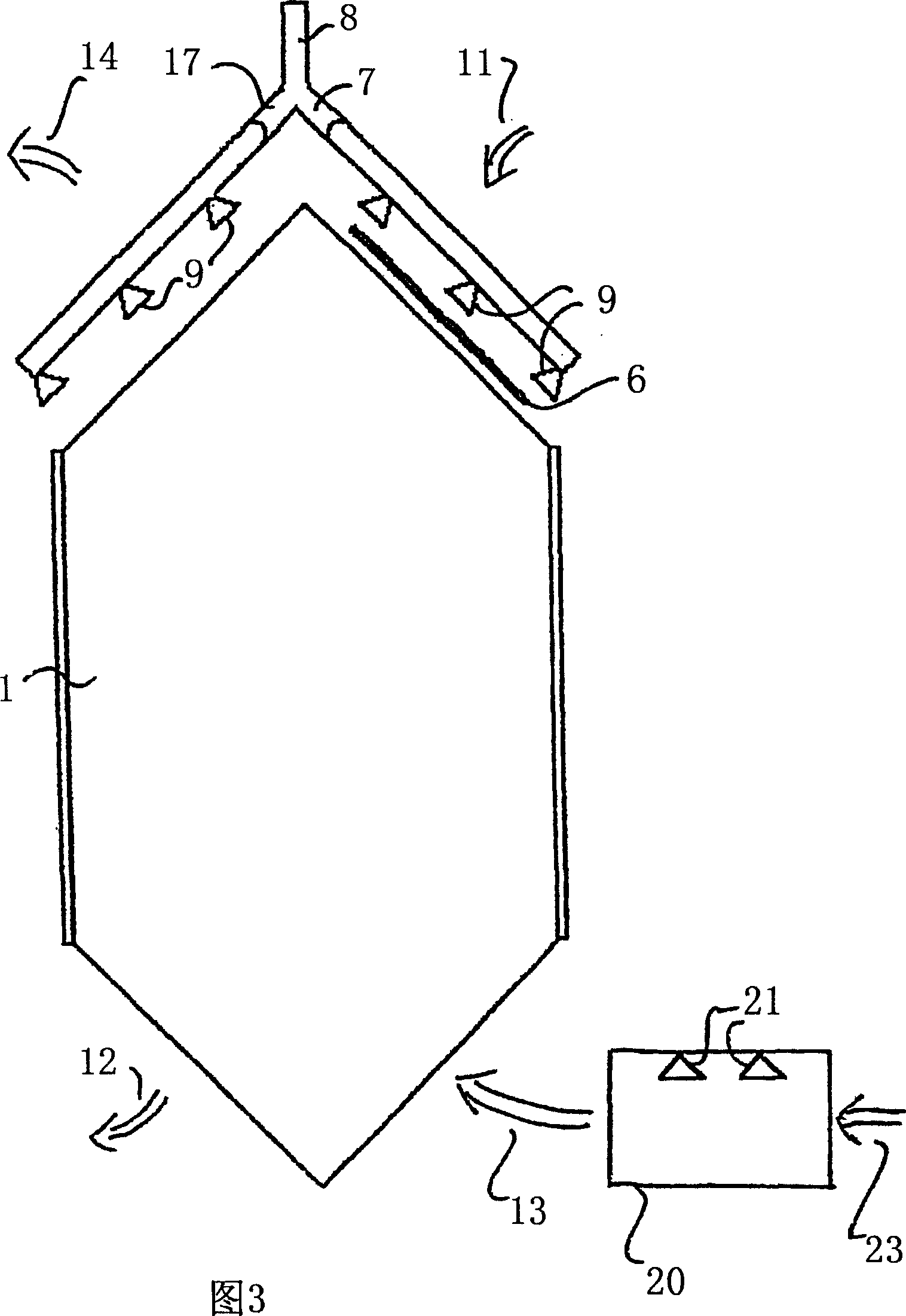

[0015] Figure 1 schematically shows a plate heat exchanger according to an exemplary embodiment of the present invention. The plate heat exchanger generally comprises a plurality of plates 1 arranged parallel to one another. The plate 1 forms a hexagonal shape, but any other shape can also be selected. The cavity created by the plate is shown in the figure 2 Among them, the reference number 2 represents the closed side wall placed opposite.

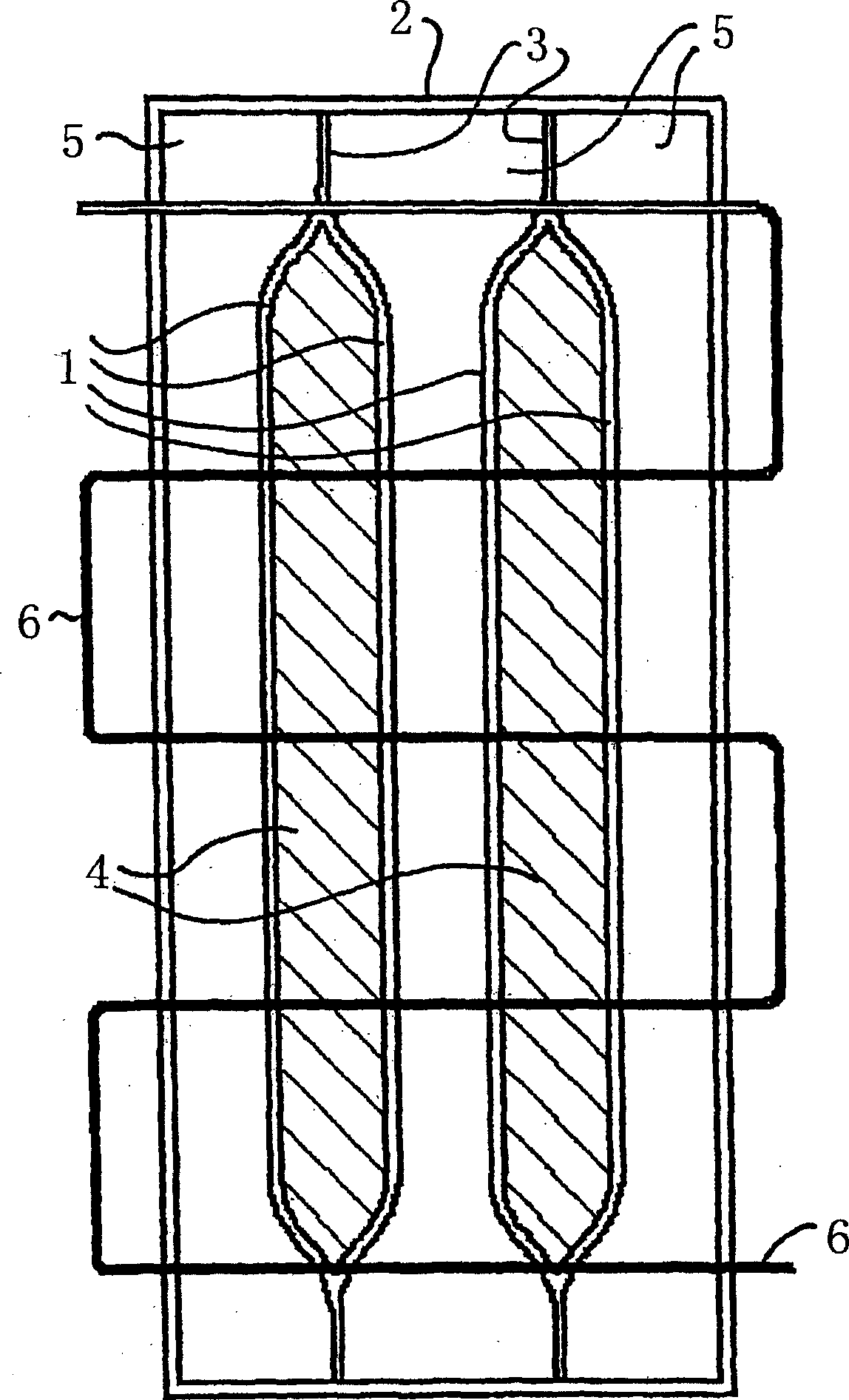

[0016] figure 2 A schematic partial view of the principle of a plate heat exchanger according to FIG. 1 is shown, with fewer plates 1 than shown in FIG. 1 . Between the side walls 2 , two pairs of plates 1 are welded together at their side end regions 3 and fastened to the outer wall 2 . Other configurations (such as glued joints) are also conceivable. This results in a cavity structure between the corresponding pair of plates 1, which are in figure 2 Marked by shading. These cavities denoted by reference numeral 4 can, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com